READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL)

INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY

INSPECT IGNITION SWITCH ASSEMBLY

READ VALUE USING INTELLIGENT TESTER

DTC P0617 Starter Relay Circuit High |

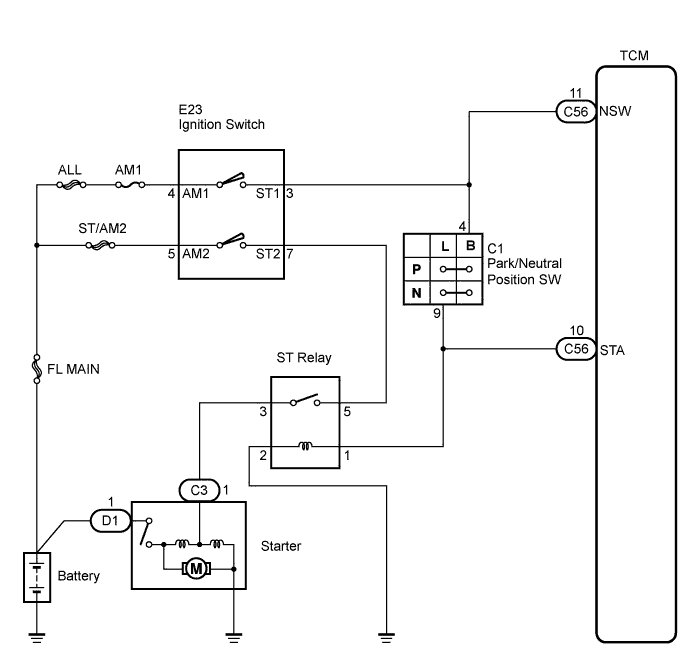

DESCRIPTION

While the engine is being cranked, the positive battery voltage is applied to terminal STA of the TCM.If the TCM detects the Starter Control (STA) signal while the vehicle is being driven, it determines that there is a malfunction in the STA circuit. The TCM then illuminates the MIL and sets the DTC.

This monitor runs when the vehicle is driven at 20 km/h (12.4 mph) for over 20 seconds.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0617 | When conditions (a), (b) and (c) are met, positive (+B) battery voltage of 10.5 V or more is applied to TCM for 20 seconds (1 trip detection logic): (a) Vehicle speed more than 20 km/h (12.4 mph) (b) Engine speed more than 1,000 rpm (c) STA signal ON |

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- The following troubleshooting flowchart is based on the premise that the engine is cranked normally. If the engine does not crank, proceed to the problem symptoms table (CAMRY_ACV40 RM000000PDG0ABX.html).

- Read freeze frame data using the intelligent tester. The TCM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction (CAMRY_ACV40 RM000000PDS01FX.html).

| 1.READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to the ON position and turn the tester on.

Enter the following menus: Powertrain / ECT / Data List.

Check the value displayed on the tester when the ignition switch is turned to the ON position and the engine is started.

- OK:

Engine Switch Condition ON (IG) ENGINE START Starter Signal OFF ON

|

| ||||

| NG | |

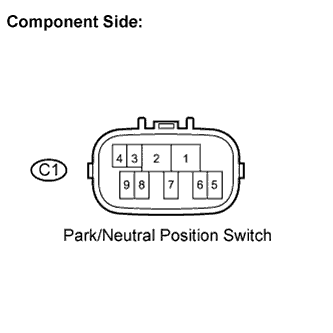

| 2.INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

Inspect the Park/Neutral Position (PNP) switch.

Disconnect the C1 switch connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Gear Selector Lever Position Tester Connection Specified Condition P 4 - 9 Below 1 Ω N 4 - 9 Below 1 Ω

Reconnect the PNP switch connector.

|

|

| ||||

| OK | |

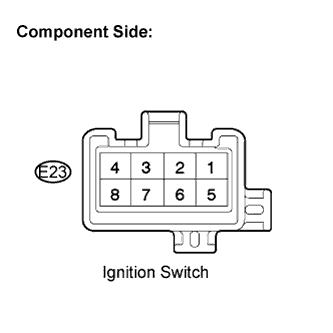

| 3.INSPECT IGNITION SWITCH ASSEMBLY |

Disconnect the E23 ignition switch connector.

|

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Switch Condition Tester Connection Specified Condition LOCK 3-4, 5-7 10 kΩ or higher START 3-4, 5-7 Below 1 Ω

Reconnect the ignition switch connector.

|

| ||||

| OK | |

| 4.READ VALUE USING INTELLIGENT TESTER |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to the ON position and turn the tester on.

Enter the following menus: Powertrain / ECT / Data List.

Check the value displayed on the tester when the ignition switch is turned to the ON position and the engine is started.

- OK:

Ignition Switch Condition ON (IG) ENGINE START Starter Signal OFF ON

|

| ||||

| OK | ||

| ||