Dtc P2716 Pressure Control Solenoid D Electrical (Shift Solenoid Valve Slt)

DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT TRANSMISSION WIRE (SLT)

CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

INSPECT SHIFT SOLENOID VALVE (SLT)

DTC P2716 Pressure Control Solenoid "D" Electrical (Shift Solenoid Valve SLT) |

DESCRIPTION

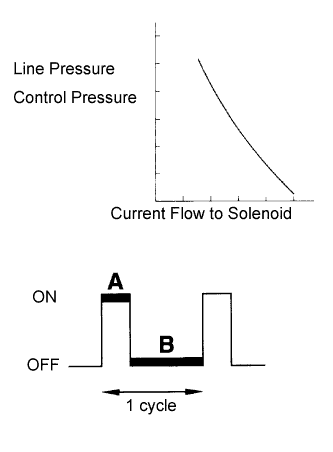

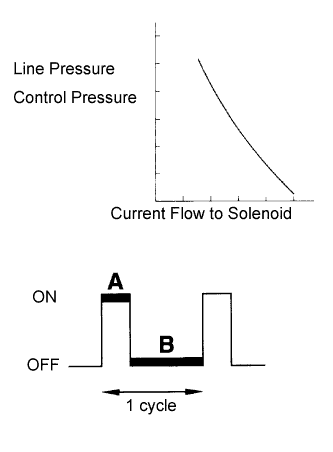

The linear solenoid valve (SLT) controls the transmission line pressure for smooth transmission operation based on signals from the throttle position sensor and the vehicle speed sensor. The ECM adjusts the duty cycle of the SLT solenoid valve to control hydraulic line pressure coming from the primary regulator valve. Appropriate line pressure assures smooth shifting with varying engine outputs.(*): Duty RatioThe duty ratio is the ratio of the period of continuity in one cycle.For example, if A is the period of continuity in one cycle, and B is the period of non-continuity, thenDuty Ratio=A/(A + B) x 100(%)DTC No.

| DTC Detection Condition

| Trouble Area

|

P2716

| Open or short is detected in shift solenoid valve SLT circuit for 1 second or more while driving (1-trip detecting logic).

| - Open or short in shift solenoid valve SLT circuit

- Shift solenoid valve SLT

- ECM

|

MONITOR DESCRIPTION

When an open or short in the linear solenoid valve (SLT) circuit is detected, the ECM interprets this as a fault. The ECM will turn on the MIL and store the DTC.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.INSPECT TRANSMISSION WIRE (SLT) |

Disconnect the transmission wire connector from the transaxle.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Specified Condition

20°C (68°F)

|

2 (SLT+) - 8 (SLT-)

| 5.0 to 5.6 Ω

|

Measure the resistance according to the value(s) in the table below.

- Standard resistance (Check for short):

Tester Connection

| Specified Condition

|

2 (SLT+) - Body ground

| 10 kΩ or higher

|

8 (SLT-) - Body ground

|

| 2.CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM) |

Connect the transmission wire connector to the transaxle.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Specified Condition

20°C (68°F)

|

C24-76 (SLT+) - C24-75 (SLT-)

| 5.0 to 5.6 Ω

|

Measure the resistance according to the value(s) in the table below.

- Standard resistance (Check for short):

Tester Connection

| Specified Condition

|

C24-76 (SLT+) - Body ground

| 10 kΩ or higher

|

C24-75 (SLT-) - Body ground

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 3.INSPECT SHIFT SOLENOID VALVE (SLT) |

Remove the shift solenoid valve (SLT).

Measure the resistance according to the value(s) in the table below.

- Standard resistance :

Tester Connection

| Specified Condition

20°C (68°F)

|

1 - 2

| 5.0 to 5.6 Ω

|

Connect the positive (+) lead with a 21 W bulb to terminal 2 and the negative (-) lead to terminal 1 of the solenoid valve connector, then check the movement of the valve.

- OK:

- The solenoid makes an operating sound.

| | REPLACE SHIFT SOLENOID VALVE (SLT) |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE TRANSMISSION WIRE |

|