Fuel Pressure Pulsation Damper Installation

INSTALL FUEL PRESSURE PULSATION DAMPER ASSEMBLY

INSTALL FUEL MAIN TUBE

INSTALL AIR CLEANER CAP SUB-ASSEMBLY

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

CHECK FOR FUEL LEAKS

INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

Fuel Pressure Pulsation Damper -- Installation |

| 1. INSTALL FUEL PRESSURE PULSATION DAMPER ASSEMBLY |

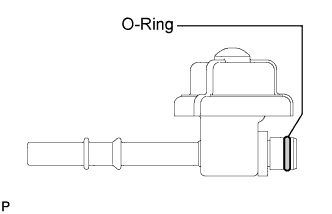

Apply a light coat of gasoline or spindle oil to the O-ring of the fuel pressure pulsation damper.

Install the fuel pressure pulsation damper with the 2 bolts.

- Torque:

- 9.0 N*m{90 kgf*cm, 80 in.*lbf}

- NOTICE:

- Make sure that the O-ring is not cracked or jammed before installing the damper.

| 2. INSTALL FUEL MAIN TUBE |

- HINT:

- Connect the metallic type connector (CAMRY_ACV40 RM000000YCO004X.html).

| 3. INSTALL AIR CLEANER CAP SUB-ASSEMBLY |

Install the air cleaner filter element onto the air cleaner case.

Insert the hinges. Install the air cleaner cap sub-assembly with the 2 bolts.

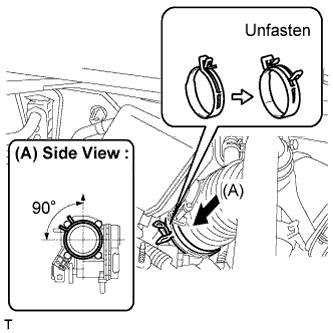

Align the matchmarks of the No. 1 air cleaner hose and throttle body, and then connect the air cleaner hose No. 1 to the throttle body and unfasten the No. 1 air cleaner hose clamp.

- NOTICE:

- Make sure that the hose clamp is at the correct angle.

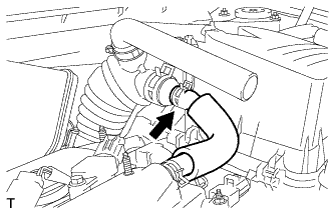

Connect the No. 2 ventilation hose to the air cleaner hose.

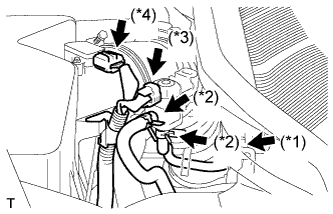

Connect the purge line hose to the clamp (*1).

Connect the 2 purge VSV vacuum hoses (*2).

Connect the purge VSV connector (*3).

Connect the mass air flow meter connector (*4).

| 4. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- HINT:

- CAMRY_ACV40 RM000000YCR003X_01_0001.html.

| 6. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY |

Install the engine cover with the 2 nuts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}