Engine Unit -- Disassembly |

| 1. REMOVE OIL FILLER CAP SUB-ASSEMBLY |

Remove the oil filler cap.

|

| 2. REMOVE OIL FILLER CAP GASKET |

Remove the oil filler cap gasket.

|

| 3. REMOVE VENTILATION VALVE SUB-ASSEMBLY |

Remove the ventilation valve.

|

| 4. REMOVE SPARK PLUG |

Remove the spark plugs.

|

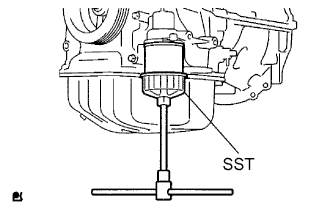

| 5. REMOVE OIL FILTER SUB-ASSEMBLY |

Using SST, remove the oil filter.

- SST

- 09228-06501

- HINT:

- Place a container for oil to be drained before removing the oil filter.

|

| 6. REMOVE OIL COOLER ASSEMBLY |

Remove the oil filter union, plate washer, nut, oil cooler and O-ring.

|

Remove the union bolt.

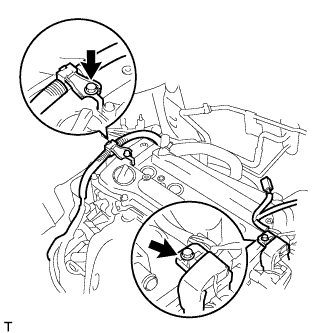

| 7. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY |

Remove the 2 bolts and disconnect the 2 engine wires.

|

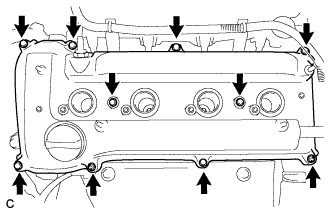

Remove the 8 bolts, 2 nuts, and the cylinder head cover.

|

| 8. REMOVE CYLINDER HEAD COVER GASKET |

Remove the cylinder head cover gasket.

|

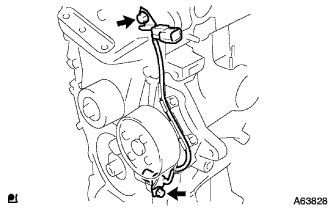

| 9. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY |

Lift the engine upward using the chain block.

- NOTICE:

- Do not lift the engine more than necessary.

Remove the bolt, nut and V-ribbed belt tensioner.

|

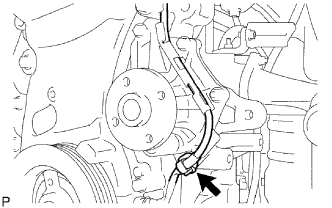

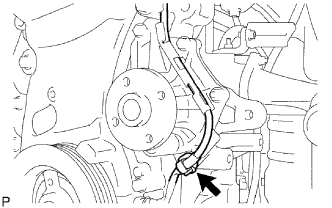

| 10. REMOVE CRANKSHAFT POSITION SENSOR |

Remove the wire harness clamp.

|

Separate the wire harness from the wire harness clamp bracket.

Remove the 2 bolts and sensor.

|

| 11. REMOVE CAMSHAFT POSITION SENSOR |

Remove the bolt and sensor.

|

| 12. REMOVE CRANKSHAFT PULLEY |

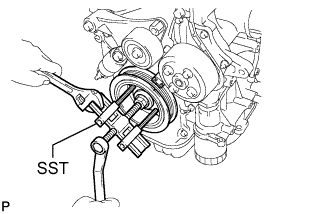

Using SST, fix the pulley in place and loosen the pulley bolt.

- SST

- 09213-54015(91651-60855)

09330-00021

|

Using SST, remove the pulley bolt and pulley.

- SST

- 09950-50013(09951-05010,09952-05010,09953-05020,09954-05021)

09950-40011(09957-04010)

- HINT:

- If necessary, remove the pulley and pulley bolt using SST.

|

| 13. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

Disconnect the camshaft timing oil control valve assembly connector.

|

Remove the bolt and camshaft timing oil control valve assembly.

| 14. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY |

Remove the 2 nuts, tensioner and gasket.

- NOTICE:

- Do not turn the crankshaft without the chain tensioner.

|

| 15. REMOVE WATER PUMP PULLEY |

|

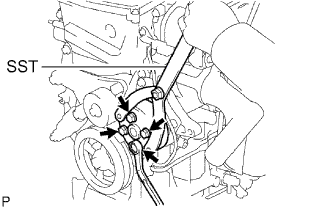

Using SST, remove the 4 bolts and water pump pulley.

- SST

- 09960-10010(09962-01000,09963-00700)

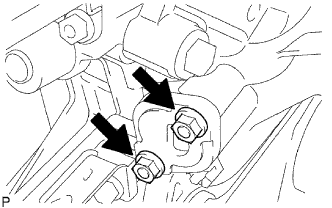

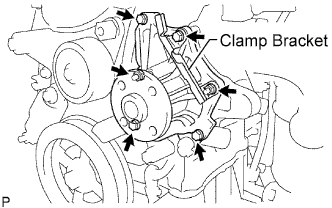

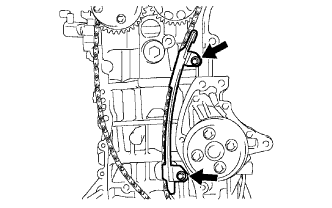

| 16. REMOVE WATER PUMP ASSEMBLY |

|

Remove the clamp of the crankshaft position sensor from the water pump.

Disconnect the wire of the crankshaft position sensor from the clamp bracket.

Remove the 4 bolts, 2 nuts and clamp bracket.

|

Using a screwdriver, pry between the water pump and cylinder block, and then remove the water pump.

- HINT:

- Tape the screwdriver tip before use.

- NOTICE:

- Be careful not to damage the contact surfaces of the water pump and cylinder block.

|

| 17. REMOVE OIL PAN DRAIN PLUG |

Remove the oil pan drain plug and gasket.

|

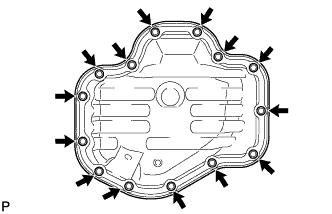

| 18. REMOVE OIL PAN SUB-ASSEMBLY |

Remove the 12 bolts and 2 nuts.

|

Insert the blade of oil pan seal cutter between the crankcase and oil pan. Cut through the sealer and remove the oil pan.

- NOTICE:

- Be careful not to damage the contact surfaces of the crankcase, chain cover and oil pan.

|

| 19. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY |

Using a E10 "TORX" socket, remove the stud bolt for the drive belt tensioner from the cylinder block.

|

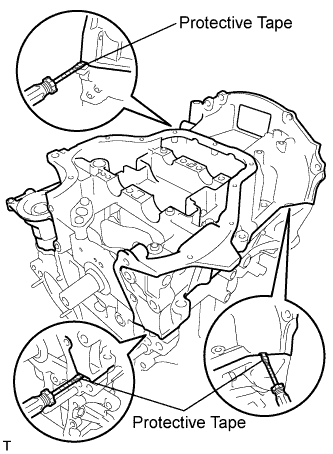

Remove the 12 bolts and 2 nuts.

Remove the timing chain cover by prying between the timing chain cover and cylinder head or cylinder block with a screwdriver.

- NOTICE:

- Be careful not to damage the contact surfaces of the timing chain cover, cylinder block and cylinder head.

- HINT:

- Tape the screwdriver tip before use.

|

| 20. REMOVE TIMING CHAIN CASE OIL SEAL |

Using a screwdriver and a hammer, remove the oil seal.

|

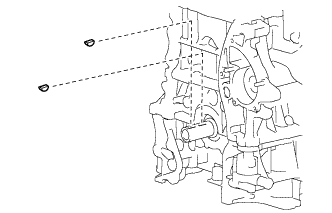

| 21. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE |

Remove the crankshaft position sensor plate.

|

| 22. REMOVE TIMING CHAIN GUIDE |

Remove the bolt and timing chain guide.

|

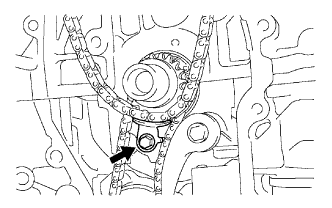

| 23. REMOVE CHAIN TENSIONER SLIPPER |

Remove the bolt and chain tensioner slipper.

|

| 24. REMOVE NO. 1 CHAIN VIBRATION DAMPER |

Remove the 2 bolts and chain vibration damper.

|

| 25. REMOVE CHAIN SUB-ASSEMBLY |

Remove the chain sub-assembly.

|

| 26. REMOVE CRANKSHAFT TIMING SPROCKET |

Remove the crankshaft timing sprocket.

|

| 27. REMOVE NO. 2 CHAIN SUB-ASSEMBLY |

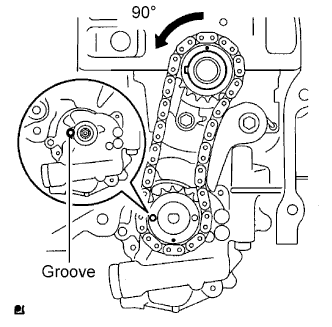

Turn the crankshaft by 90° counterclockwise to align the adjusting hole of the oil pump drive shaft sprocket with the groove of the oil pump.

|

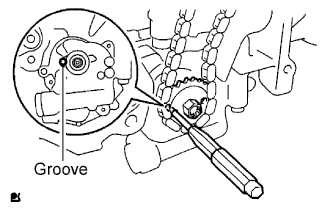

Insert a 4 mm diameter bar into the adjusting hole of the oil pump drive shaft sprocket to lock the gear in position, and then remove the nut.

|

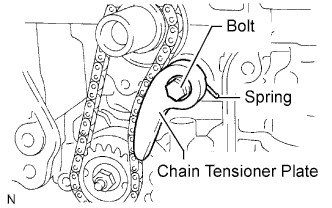

Remove the bolt, chain tensioner plate and spring.

|

Remove the chain tensioner, oil pump driven sprocket and chain.

|

| 28. REMOVE KEYS |

Remove the 2 pulley set keys from the crankshaft.

|

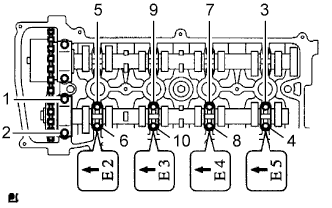

| 29. REMOVE NO. 2 CAMSHAFT |

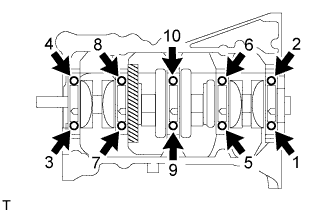

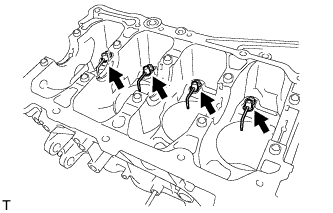

Using several steps, uniformly loosen and remove the 10 bearing cap bolts in the sequence shown in the illustration.

|

Remove the 5 bearing caps.

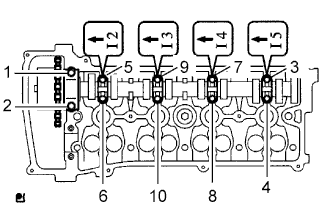

| 30. REMOVE CAMSHAFT |

Using several steps, uniformly loosen and remove the 10 bearing cap bolts in the sequence shown in the illustration.

|

Remove the 5 bearing caps.

| 31. REMOVE NO. 1 CAMSHAFT BEARING |

|

| 32. REMOVE NO. 2 CAMSHAFT BEARING |

Remove the No. 2 camshaft bearing.

|

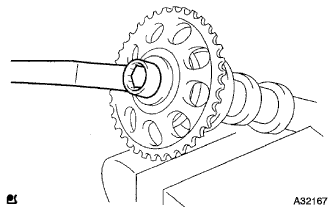

| 33. REMOVE CAMSHAFT TIMING SPROCKET |

Clamp the camshaft in a vise.

|

Remove the flange bolt of the camshaft timing sprocket.

| 34. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY |

Clamp the camshaft in a vise, and make sure that the camshaft timing gear does not rotate.

|

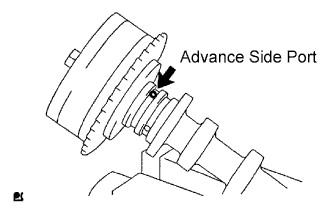

Cover all the oil ports except the advance side port shown in the illustration with vinyl tape.

Apply air pressure of 100 kPa (1.0 kgf/cm2, 14 psi) to the oil path, then turn the camshaft timing gear in the advance direction (counterclockwise) by hand.

- CAUTION:

- Cover the paths with a shop rag or piece of cloth to avoid oil splashes.

- HINT:

- Depending on the air pressure, the camshaft timing gear will turn to the advance angle side without applying force by hand. Also, if the pressure is difficult to apply because of air leakage from the port, the lock may be difficult to release.

|

Remove the flange bolt of the camshaft timing gear.

- NOTICE:

- Be sure not to remove the other 4 bolts.

- If planning to reuse the gear, be sure to release the straight pin lock before installing the gear.

|

| 35. REMOVE CYLINDER HEAD SUB-ASSEMBLY |

Using several steps, uniformly loosen and remove the 10 cylinder head bolts and 10 plate washers with a 10 mm bi-hexagon wrench in the sequence shown in the illustration.

- NOTICE:

- Head warpage or cracking could result from removing the bolts in the wrong order.

|

Using a screwdriver with its tip wrapped with tape, pry between the cylinder head and cylinder block, and remove the cylinder head.

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder head and cylinder block.

|

| 36. REMOVE CYLINDER HEAD GASKET |

Remove the cylinder head gasket.

|

| 37. REMOVE CYLINDER BLOCK WATER JACKET SPACER |

Using needle-nose pliers, remove the cylinder block water jacket spacer.

- NOTICE:

- Be sure to remove the water jacket spacer if turning the cylinder block upside down.

|

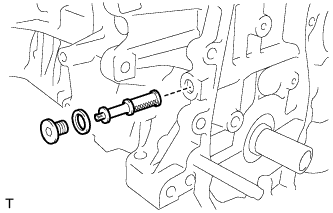

| 38. REMOVE OIL CONTROL VALVE FILTER |

Using an 8 mm socket hexagon wrench, remove the plug and filter.

|

| 39. REMOVE OIL PUMP ASSEMBLY |

Remove the 3 bolts, oil pump and gasket.

|

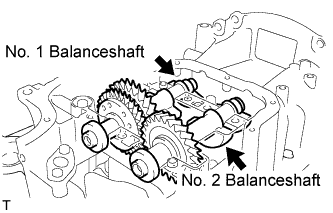

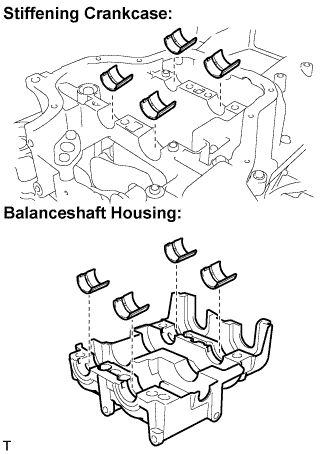

| 40. REMOVE NO. 1 AND NO. 2 BALANCESHAFT SUB-ASSEMBLY |

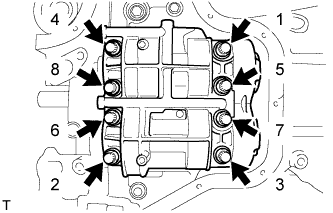

Uniformly loosen and remove the 8 bolts in the sequence shown in the illustration.

|

Remove the No. 1 and No. 2 balanceshafts.

|

| 41. REMOVE NO. 1 BALANCESHAFT BEARING |

Remove the balanceshaft bearings.

|

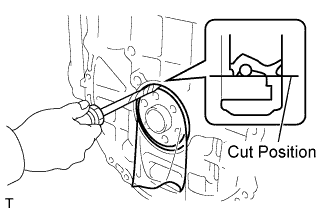

| 42. REMOVE ENGINE REAR OIL SEAL |

Using a knife, cut off the oil seal lip.

|

Using a screwdriver with its tip taped, pry out the oil seal.

- NOTICE:

- After removing the oil seal, check the crankshaft for damage. If it is damaged, smooth the surface with 400-grit sandpaper.

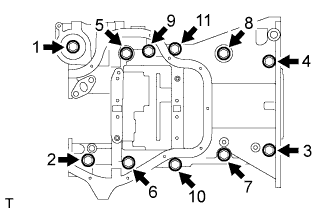

| 43. REMOVE STIFFENING CRANKCASE ASSEMBLY |

Uniformly loosen and remove the 11 bolts in the sequence shown in the illustration.

|

Using a screwdriver, remove the crankcase by prying between the crankcase and cylinder block.

- NOTICE:

- Be careful not to damage the contact surfaces of the crankcase and cylinder block.

|

Remove the O-ring from the cylinder block.

|

| 44. REMOVE PISTON SUB-ASSEMBLY WITH CONNECTING ROD |

Using a ridge reamer, remove all the carbon from the top of the cylinder.

|

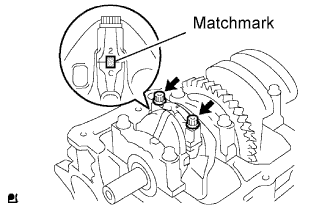

Check that the matchmarks on the connecting rod and cap are aligned to ensure the correct reassembly.

- HINT:

- The matchmarks on the connecting rods and caps are provided for ensuring the correct reassembly.

|

Using a 12 mm socket wrench, uniformly loosen the 2 bolts.

|

Using the 2 removed connecting rod cap bolts, remove the connecting rod cap and lower bearing by wiggling the connecting rod cap right and left.

- HINT:

- Keep the lower bearing inserted in the connecting rod cap.

Push the piston, connecting rod assembly and upper bearing through the top of the cylinder block.

- HINT:

- Keep the bearing, connecting rod and cap together.

- Arrange the piston and connecting rod assemblies in the correct order.

| 45. REMOVE CONNECTING ROD BEARING |

Remove the connecting rod bearings.

- HINT:

- Arrange the removed parts in the correct order.

| 46. REMOVE PISTON RING SET |

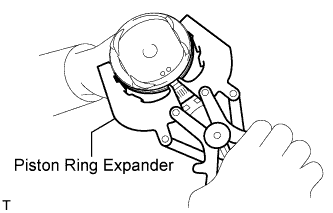

Using a piston ring expander, remove the 2 compression rings.

|

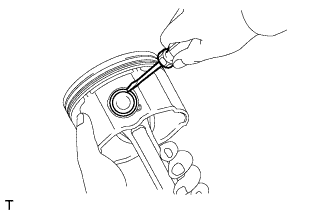

Remove the oil ring rail and oil ring expander by hand.

- HINT:

- Arrange the removed parts in the correct order.

| 47. REMOVE PISTON PIN HOLE SNAP RING |

Using a screwdriver, pry out the 2 snap rings.

|

| 48. REMOVE PISTON |

Gradually heat the piston to approximately 80 to 90°C (176 to 194°F).

|

Using a plastic hammer and brass bar, lightly tap out the piston pin and remove the connecting rod.

- HINT:

- The piston and pin are a matched set.

- Arrange the pistons, pins, rings, connecting rods and bearings in the correct order.

|

| 49. REMOVE CRANKSHAFT |

Uniformly loosen and remove the 10 main bearing cap bolts in the sequence shown in the illustration.

|

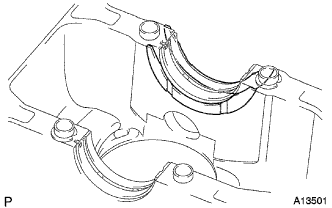

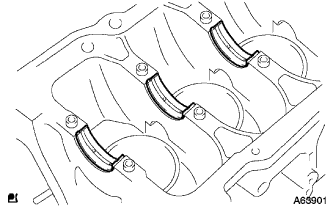

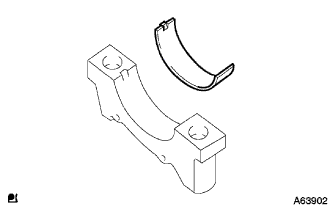

Use 2 removed main bearing cap bolts to remove the 5 main bearing caps and 5 lower bearings.

- NOTICE:

- Insert the bolts into one of the caps. Ease the cap out by gently pulling up and applying force toward the front and back side of the cylinder block, as shown in the illustration. Take care not to damage the contact surfaces of the cap and cylinder block.

- HINT:

- Keep the lower bearing and main bearing cap together.

- Arrange the main bearing caps in the correct order.

|

Lift out the crankshaft.

| 50. REMOVE UPPER CRANKSHAFT THRUST WASHER |

Remove the upper thrust washers from the cylinder block.

|

| 51. REMOVE CRANKSHAFT BEARING |

Remove the 5 upper main bearings from the cylinder block.

- HINT:

- Arrange the bearings in the correct order.

|

| 52. REMOVE NO. 2 CRANKSHAFT BEARING |

Remove the 5 lower main bearings from the 5 main bearing caps.

- HINT:

- Arrange the bearings in the correct order.

|

| 53. REMOVE STUD BOLT |

| 54. REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY |

Using a 5 mm hexagon wrench, remove the bolts and oil nozzles.

|

| 55. CLEAN CYLINDER BLOCK |

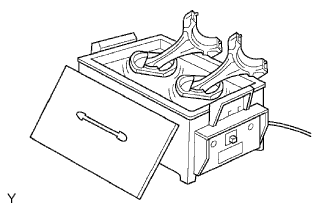

- NOTICE:

- If the cylinder is washed at high temperatures, the cylinder liner will stick out beyond the cylinder block. Always wash the cylinder block at a temperature of 45°C (113°F) or less.