Dtc P0016 Crankshaft Position - Camshaft Position Correlation (Bank 1 Sensor A)

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK VALVE TIMING (CHECK FOR LOOSE AND A JUMPED TOOTH OF TIMING CHAIN)

DTC P0016 Crankshaft Position - Camshaft Position Correlation (Bank 1 Sensor A) |

DTC P0017 Crankshaft Position - Camshaft Position Correlation (Bank 1 Sensor B) |

DTC P0018 Crankshaft Position - Camshaft Position Correlation (Bank 2 Sensor A) |

DTC P0019 Crankshaft Position - Camshaft Position Correlation (Bank 2 Sensor B) |

DESCRIPTION

In the VVT system, the appropriate intake and exhaust valve open and close timings are controlled by the ECM. The ECM performs intake and exhaust valve control by performing the following: 1) controlling the camshaft and camshaft oil control valve, and operating the camshaft timing gear; and 2) changing the relative positions of the gaps between the camshaft and crankshaft.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0016

| Deviation in crankshaft position sensor signal and VVT sensor 1 (for intake camshaft (bank 1)) signal (2 trip detection logic)

| - Mechanical system (Timing chain has jumped teeth or chain stretched)

- ECM

|

P0017

| Deviation in crankshaft position sensor signal and VVT sensor 1 (for exhaust camshaft (bank 1)) signal (2 trip detection logic)

| - Mechanical system (Timing chain has jumped teeth or chain stretched)

- ECM

|

P0018

| Deviation in crankshaft position sensor signal and VVT sensor 2 (for intake camshaft (bank 2)) signal (2 trip detection logic)

| - Mechanical system (Timing chain has jumped teeth or chain stretched)

- ECM

|

P0019

| Deviation in crankshaft position sensor signal and VVT sensor 2 (for exhaust camshaft (bank 2)) signal (2 trip detection logic)

| - Mechanical system (Timing chain has jumped teeth or chain stretched)

- ECM

|

WIRING DIAGRAM

Refer to DTC P0335 (Link).

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction (CAMRY_ACV40 RM000000PDS01FX.html).

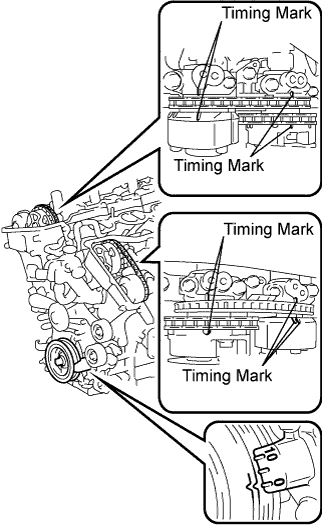

| 1.CHECK VALVE TIMING (CHECK FOR LOOSE AND A JUMPED TOOTH OF TIMING CHAIN) |

Remove the cylinder head covers RH and LH.

Turn the crankshaft pulley, and align its groove with the timing mark "0" of the timing chain cover.

Check that the timing marks of the camshaft timing gears are aligned with the timing marks of the bearing cap as shown in the illustration.

If not, turn the crankshaft 1 revolution (360°), then align the marks as above.

- OK:

- Timing marks on the camshaft timing gears are aligned as shown in the illustration.

Reinstall the cylinder head covers.

| | ADJUST VALVE TIMING (REPAIR OR REPLACE TIMING CHAIN) |

|

|