Torque Converter Clutch And Drive Plate -- Inspection |

| 1. INSPECT TORQUE CONVERTER ASSEMBLY |

Inspect the one-way clutch.

Press on the splines of the stator with a finger and rotate it. Check that it rotates smoothly when turned clockwise and rotates with difficulty when turned counterclockwise.

If necessary, clean the converter and recheck the one-way clutch.

Replace the converter if the one-way clutch still fails the inspection.

|

Determine the condition of the torque converter clutch assembly.

If the inspection result of the torque converter clutch assembly satisfies the following conditions, replace the torque converter clutch assembly.

Malfunction:- A metallic sound is emitted from the torque converter clutch assembly during the stall test or when the shift lever is moved to N.

- The one-way clutch is free or locked in both directions.

- The amount of powder in the fluid is more than the sample shown in the illustration.

- HINT:

- The sample shows approximately 0.025 liters (0.026 US qts, 0.022 Imp. qts) of fluid that is taken out from the removed torque converter clutch.

- A metallic sound is emitted from the torque converter clutch assembly during the stall test or when the shift lever is moved to N.

|

Replace the fluid in the torque converter clutch.

If the fluid is discolored and/or has a foul odor, stir the fluid in the torque converter clutch and drain it.

Clean and check the oil cooler and oil pipe line.

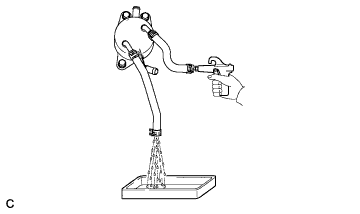

If the torque converter is inspected or the fluid is changed, clean the oil cooler and oil pipe line.

- HINT:

- Apply compressed air at 196 kPa (2 kgf/cm2, 28 psi) into the inlet hose.

- If an excessive amount of fine powder is found in the fluid, add new fluid using a bucket pump and clean the oil cooler and oil pipe line again.

- NOTICE:

- When inserting the air gun into the inlet hose, be sure not to damage the inside of the hose.

If the fluid is cloudy, inspect the oil cooler.

Prevent deformation of the torque converter clutch and damage to the oil pump gear.

When there is any damage to the end of the bolt for the torque converter and to the bottom of the bolt hole, replace the bolt and torque converter.

Make sure all of the bolts are the same length.

Bolts with washers must be used.

|

| 2. INSPECT DRIVE PLATE |

Check the drive plate for damage.

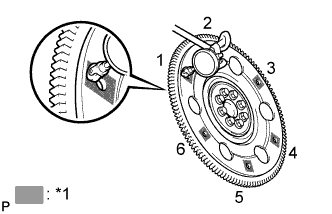

Set up a dial indicator and measure the runout of the 6 portions around the torque converter fitting surfaces.

Text in Illustration *1 Measurement Point - Maximum runout:

- 0.30 mm (0.0118 in.)

If installing a new dive plate, be careful of the orientation of the spacers and tighten the bolts (RAV4_ACA30 RM000003PXK003X_01_0069.html).

|