Dtc P0715 Input/Turbine Speed Sensor A Circuit

K111F Cvt. Toyota Rav4. Aca30, 33, 38 Gsa33 Zsa30, 35

DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

READ VALUE USING INTELLIGENT TESTER (SPD (NT) AND NT SENSOR VOLTAGE)

INSPECT TRANSMISSION REVOLUTION SENSOR (NT)

CHECK HARNESS AND CONNECTOR (TRANSMISSION REVOLUTION SENSOR (NT) - ECM)

REPLACE ECM

PERFORM INITIALIZATION

REPLACE ECM

PERFORM INITIALIZATION

DTC P0715 Input/Turbine Speed Sensor "A" Circuit |

DTC P0717 Input/Turbine Speed Sensor "A" Circuit No Signal |

DESCRIPTION

The ECM receives a signal from the turbine speed sensor (transmission revolution sensor (NT)) installed in the continuously variable transaxle to control the lock-up engagement pressure and forward and reverse clutch pressure.The transmission revolution sensor (NT) detects the continuously variable transaxle input shaft speed and sends it to the ECM.DTC Code

| DTC Detection Condition

- Diagnosis Condition

- Malfunction Status

- Malfunction Time

- Other

| Trouble Area

|

P0715

| - A transmission revolution sensor (NT) signal malfunction is not detected.

- The transmission revolution sensor (NT) output voltage is less than 0.1 V, or higher than 1.9 V.

- 2 seconds

- 1 trip detection logic

| - Open or short in transmission revolution sensor (NT) circuit

- Transmission revolution sensor (NT)

- ECM

|

P0717

| - The vehicle is driven with the shift lever in D, the output shaft speed is 300 rpm or more, and no error is detected in the park/neutral position switch.

- The speed indicated by the transmission revolution sensor (NT) is less than 300 rpm.

- 2 seconds

- 1 trip detection logic

| - Open or short in transmission revolution sensor (NT) circuit

- Transmission revolution sensor (NT)

- ECM

|

MONITOR DESCRIPTION

The turbine speed sensor detects the transaxle input shaft speed. The ECM determines the necessary gear ratio based on a comparison of the turbine speed sensor (input shaft speed) with the output speed sensor (output shaft speed).When the output shaft speed is higher than the expected value and the input shaft speed is less than 300 rpm while driving with the shift lever in D, the ECM will conclude that there is a malfunction in the transmission revolution sensor (NT). The ECM will illuminate the MIL and store the DTC.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.READ VALUE USING INTELLIGENT TESTER (SPD (NT) AND NT SENSOR VOLTAGE) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List.

In accordance with the display on the tester, read the Data List.

Engine and ECTTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

SPD (NT)

| Input turbine speed/

min.: 0 rpm

max.: 12750 rpm

| - Lock-up on (After warming up engine): Input turbine speed (NT) equal to engine speed

- Lock-up off (Idling with shift lever in P or N): Input turbine speed (NT) nearly equal to engine speed

- Vehicle stopped with shift lever in R: 0 rpm

| Data is displayed in increments of 50 rpm.

|

NT Sensor Voltage

| Input turbine speed (NT) sensor output voltage/

min.: 0 V

max.: 5 V

| Engine idling (Vehicle stopped with shift lever in P or N): Constantly changes between 0.8 to 1.6 V and 2.4 to 3.2 V

| -

|

ResultResult

| Proceed to

|

Data displayed is not as specified under Normal Condition

| A

|

Data displayed is as specified under Normal Condition

| B

|

| 2.INSPECT TRANSMISSION REVOLUTION SENSOR (NT) |

Remove the transmission revolution sensor (NT) (RAV4_ACA30 RM000000OE402CX.html).

Connect the battery to the sensor as shown in the illustration.

Wave a magnetic object left and right in front of the transmission revolution sensor (NT) tip (5 mm (0.197 in.) gap or closer) to change the high/low signals while measuring the current.

- NOTICE:

- Make sure to wave the magnetic object during the inspection. The current will not change without waving the magnetic object as indicated by the arrow in the illustration.

Measure the current according to the value(s) in the table below.

- Standard Current:

Tester Connection

| Condition

| Specified Condition

|

1 - 2

| Low signal

| 4 to 8 mA

|

1 - 2

| High signal

| 12 to 16 mA

|

Text in Illustration*1

| Component without harness connected

(Transmission Revolution Sensor (NT))

|

*2

| Ammeter

|

*3

| Battery

|

*4

| 5 mm (0.197 in.) Gap or Closer

|

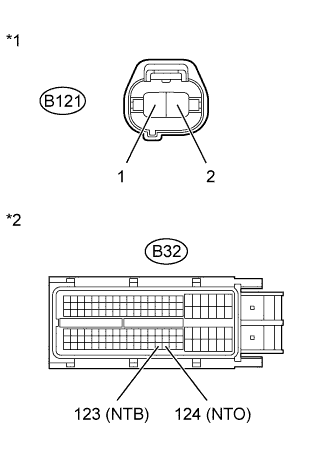

| 3.CHECK HARNESS AND CONNECTOR (TRANSMISSION REVOLUTION SENSOR (NT) - ECM) |

Disconnect the transmission revolution sensor (NT) connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

B121-1 - B32-124 (NTO)

| Always

| Below 1 Ω

|

B121-2 - B32-123 (NTB)

| Always

| Below 1 Ω

|

B121-1 or B32-124 (NTO) - Body ground

| Always

| 10 kΩ or higher

|

B121-2 or B32-123 (NTB) - Body ground

| Always

| 10 kΩ or higher

|

Text in Illustration*1

| Front view of wire harness connector

(to Transmission Revolution Sensor (NT))

|

*2

| Front view of wire harness connector

(to ECM)

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

Replace the ECM (RAV4_ACA30 RM0000017UO01KX.html).

- NOTICE:

- Performing reset memory will clear the learned values of both the yaw rate sensor assembly*1 or deceleration sensor*2 (deceleration sensor 0 point calibration) and CVT oil pressure (CVT oil pressure calibration). Make sure to perform reset memory, yaw rate sensor assembly*1 or deceleration sensor*2 0 point calibration and CVT oil pressure calibration when replacing any of the parts shown in the following table:

Replaced Part

|

- Continuously variable transaxle assembly

- ECM

- Oil pressure sensor

- Yaw rate sensor assembly (w/ VSC)

- Deceleration sensor (w/o VSC)

- Brake actuator assembly (skid control ECU)

|

- After performing reset memory, always perform yaw rate sensor assembly*1 or deceleration sensor*2 (deceleration sensor 0 point) calibration first, and then CVT oil pressure calibration.

- Always perform 0 point calibration with the vehicle on level ground.

- Do not shake or vibrate the vehicle during 0 point calibration.

Using the intelligent tester, perform reset memory, deceleration sensor 0 point calibration and CVT oil pressure calibration (RAV4_ACA30 RM000003UQR002X.html).

Check that no DTC is stored.

Replace the ECM (RAV4_ACA30 RM0000017UO01KX.html).

- NOTICE:

- Performing reset memory will clear the learned values of both the yaw rate sensor assembly*1 or deceleration sensor*2 (deceleration sensor 0 point calibration) and CVT oil pressure (CVT oil pressure calibration). Make sure to perform reset memory, yaw rate sensor assembly*1 or deceleration sensor*2 0 point calibration and CVT oil pressure calibration when replacing any of the parts shown in the following table:

Replaced Part

|

- Continuously variable transaxle assembly

- ECM

- Oil pressure sensor

- Yaw rate sensor assembly (w/ VSC)

- Deceleration sensor (w/o VSC)

- Brake actuator assembly (skid control ECU)

|

- After performing reset memory, always perform yaw rate sensor assembly*1 or deceleration sensor*2 (deceleration sensor 0 point) calibration first, and then CVT oil pressure calibration.

- Always perform 0 point calibration with the vehicle on level ground.

- Do not shake or vibrate the vehicle during 0 point calibration.

Using the intelligent tester, perform reset memory, deceleration sensor 0 point calibration and CVT oil pressure calibration (RAV4_ACA30 RM000003UQR002X.html).

Check that no DTC is stored.