Underdrive Clutch Disassembly

INSPECT UNDERDRIVE PACK CLEARANCE

REMOVE UNDERDRIVE CLUTCH FLANGE NO. 2 HOLE SNAP RING

REMOVE NO. 1 UNDERDRIVE CLUTCH DISC

REMOVE UNDERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY

REMOVE UNDERDRIVE CLUTCH PISTON SET

REMOVE UNDERDRIVE CLUTCH DRUM O-RING

Underdrive Clutch -- Disassembly |

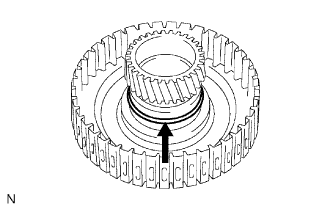

| 1. INSPECT UNDERDRIVE PACK CLEARANCE |

Install the underdrive clutch to the transaxle case.

- NOTICE:

- Be careful not to damage the oil seal rings.

Install a dial indicator as shown in the illustration.

Measure the underdrive clutch pack clearance while applying and releasing compressed air (392 kPa, 4.0 kgf/cm2, 57 psi).

- Standard pack clearance:

- 1.51 to 1.71 mm (0.0594 to 0.0673 in.)

If the pack clearance is not as specified, inspect the discs, plates and flange.

- HINT:

- There are 5 different thicknesses of flanges available.

- Standard flange thickness:

Mark

| Thickness

| Mark

| Thickness

|

1

| 3.0 mm (0.118 in.)

| 4

| 3.6 mm (0.142 in.)

|

2

| 3.2 mm (0.126 in.)

| 5

| 3.8 mm (0.150 in.)

|

3

| 3.4 mm (0.134 in.)

| -

| -

|

| 2. REMOVE UNDERDRIVE CLUTCH FLANGE NO. 2 HOLE SNAP RING |

Using a screwdriver, remove the snap ring.

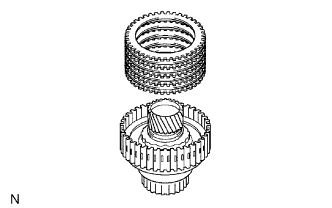

| 3. REMOVE NO. 1 UNDERDRIVE CLUTCH DISC |

Remove the flange, 4 discs and 4 plates from the underdrive clutch drum.

| 4. REMOVE UNDERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY |

Place SST on the clutch balancer and compress the spring with a press.

- SST

- 09350-32014

Using a snap ring expander, remove the snap ring.

- NOTICE:

- Stop the press when the spring seat is lowered to a position 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove. This prevents the spring seat from being deformed.

- Do not expand the snap ring excessively.

Remove the clutch balancer from the underdrive clutch drum.

Remove the return spring from the underdrive clutch drum.

| 5. REMOVE UNDERDRIVE CLUTCH PISTON SET |

Install the underdrive clutch to the transaxle case.

- NOTICE:

- Be careful not to damage the oil seal ring.

Holding the underdrive clutch piston by hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the transaxle case to remove the underdrive clutch piston.

| 6. REMOVE UNDERDRIVE CLUTCH DRUM O-RING |

Using a screwdriver, remove the O-ring from the underdrive clutch drum.