Front Crankshaft Oil Seal Installation

Engine. Toyota Rav4. Aca30, 33, 38 Gsa33 Zsa30, 35

INSTALL TIMING CHAIN COVER OIL SEAL

INSTALL CRANKSHAFT PULLEY

INSTALL V-RIBBED BELT

ADJUST V-RIBBED BELT

INSPECT V-RIBBED BELT

INSTALL FRONT SUSPENSION MEMBER REINFORCEMENT RH

ADD ENGINE OIL

INSPECT FOR OIL LEAK

INSTALL REAR ENGINE UNDER COVER RH

INSTALL NO. 1 ENGINE UNDER COVER

INSTALL FRONT WHEEL RH

INSTALL NO. 2 CYLINDER HEAD COVER

Front Crankshaft Oil Seal -- Installation |

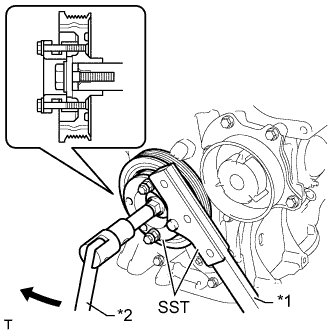

| 1. INSTALL TIMING CHAIN COVER OIL SEAL |

Apply MP grease to the lip of a new oil seal.

- NOTICE:

- Do not allow foreign matter to contact the lip of the oil seal.

- Do not allow MP grease to contact the dust seal.

Using SST and a hammer, tap in the oil seal until its surface is flush with the timing chain cover edge.

- SST

- 09223-22010

- NOTICE:

- Wipe off any extra grease from the crankshaft.

- Do not tap in the oil seal at an angle.

| 2. INSTALL CRANKSHAFT PULLEY |

Align the key groove of the pulley with the pulley set key.

Temporarily install the pulley with the pulley bolt.

Using SST, hold the pulley in place and tighten the pulley bolt.

Text in Illustration*1

| Hold

|

*2

| Turn

|

- SST

- 09330-00021

09213-58014(91551-80840)

- Torque:

- 190 N*m{1940 kgf*cm, 140 ft.*lbf}

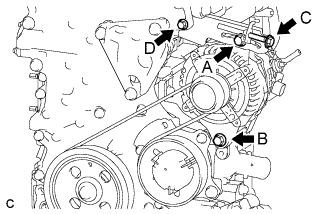

Temporarily install the V-ribbed belt.

Turn bolt C to adjust the tension of the V-ribbed belt.

Tighten bolts A and B.

- Torque:

- for bolt A:

- 19 N*m{189 kgf*cm, 14 ft.*lbf}

- for bolt B:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

- NOTICE:

- Do not loosen bolt D.

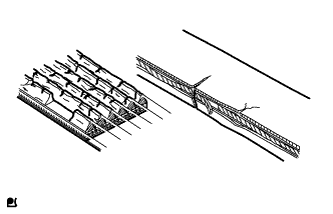

Check the belt for wear, cracks or other signs of damage.

If any of the following defects is found, replace the V-ribbed belt.

- The belt is cracked.

- The belt is worn out to the extent that the cords are exposed.

- The belt has chunks missing from the ribs.

Check that the belt fits properly in the ribbed grooves.

- HINT:

- Check with your hand to confirm that the belt has not slipped out of the grooves on the bottom to the pulley. If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt correctly.

|

Check the V-ribbed belt deflection and tension.

- Standard Deflection:

Item

| Specified Condition

|

New belt

| 7.0 to 8.2 mm (0.276 to 0.323 in.)

|

Used belt

| 7.6 to 10.0 mm (0.299 to 0.394 in.)

|

- Standard Tension:

Item

| Specified Condition

|

New belt

| 700 to 800 N (70 to 80 kgf, 157.4 to 179.8 lbf)

|

Used belt

| 550 to 750 N (55 to 75 kgf, 123.6 to 168.6 lbf)

|

- HINT:

- When inspecting the V-ribbed belt deflection, apply 98 N (10 kgf, 22.0 lbf) of tensile force to it.

- Check the V-ribbed belt deflection at the specified point.

- V-ribbed belt tension and deflection should be checked after 2 revolutions of engine cranking.

- Measure the belt tension when the engine is cold.

- When adjusting the belt, be sure to adjust it so that the tension is as close as possible to the median of the specified range.

- When replacing the belt with a new one, be sure to perform the following after adjusting the belt: idle the engine for 5 minutes, and then adjust the belt to the specified value for a new belt after the engine has cooled.

- When inspecting a belt which has been used for over 5 minutes, apply the used belt specifications.

- When using a belt tension gauge, confirm its accuracy by using a master gauge first.

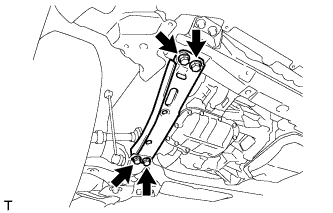

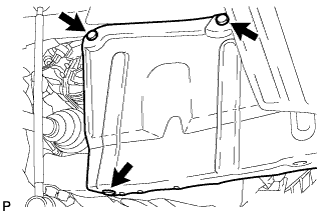

| 6. INSTALL FRONT SUSPENSION MEMBER REINFORCEMENT RH |

Install the reinforcement with the 4 bolts.

- Torque:

- 96 N*m{979 kgf*cm, 71 ft.*lbf}

Clean and install the oil pan drain plug together with a new gasket.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

Add new engine oil.

- Standard Oil Grade:

Oil Grade

| Oil Viscosity (SAE)

|

API grade SL or SM multigrade engine oil

| - 15W-40

- 20W-50

|

API grade SL "Energy-Conserving", SM "Energy-Conserving" or ILSAC multigrade engine oil

| - 0W-20

- 5W-20

- 5W-30

- 10W-30

|

- Standard Capacity:

Item

| Specified Condition

|

Drain and refill without oil filter change

| 3.9 liters (4.1 US qts, 3.4 Imp. qts)

|

Drain and refill with oil filter change

| 4.2 liters (4.4 US qts, 3.7 Imp. qts)

|

Dry fill

| 4.7 liters (5.0 US qts, 4.1 Imp. qts)

|

Install the oil filler cap.

Start the engine. Make sure that there are no oil leaks from the areas that were worked on.

| 9. INSTALL REAR ENGINE UNDER COVER RH |

Install the under cover with the 3 clips.

| 10. INSTALL NO. 1 ENGINE UNDER COVER |

Install the under cover with the 6 screws and 10 clips.

| 11. INSTALL FRONT WHEEL RH |

- Torque:

- 103 N*m{1050 kgf*cm, 76 ft.*lbf}

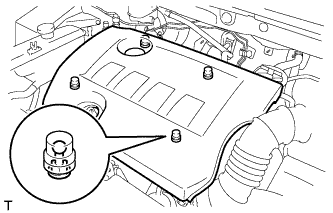

| 12. INSTALL NO. 2 CYLINDER HEAD COVER |

Attach the 4 clips to install the cover.

- NOTICE:

- Be sure to attach the clips securely.

- Do not apply excessive force or do not hit the cover to attach the clips. This may cause the cover to break.