Cylinder Block -- Inspection |

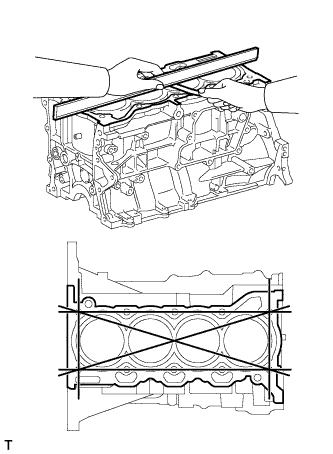

| 1. INSPECT CYLINDER BLOCK FOR WARPAGE |

Using a straightedge and feeler gauge, measure the warpage of the surface that contacts the cylinder head gasket.

- Maximum warpage:

- 0.05 mm (0.00197 in.)

|

| 2. INSPECT CYLINDER BORE |

Using a cylinder gauge, measure the cylinder bore diameter at positions A and B in both the thrust and axial directions.

- Standard diameter:

- 80.500 to 80.513 mm (3.169 to 3.170 in.)

- Maximum diameter:

- 80.633 mm (3.1745 in.)

- Measurement Position:

Measurement Position Cylinder Bore Position A 10 mm (0.394 in.) from top edge B 50 mm (1.97 in.) from top edge

|

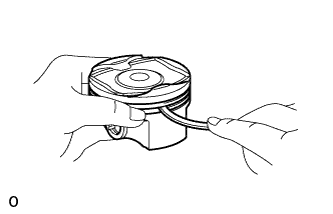

| 3. INSPECT PISTON |

Using a gasket scraper, remove the carbon from the piston top.

|

Using a groove cleaning tool or broken ring, clean the piston ring grooves.

|

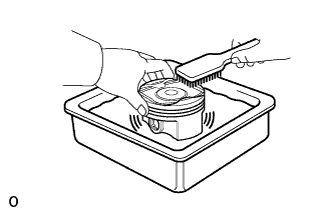

Using a brush and solvent, thoroughly clean the piston.

- NOTICE:

- Do not use a wire brush.

|

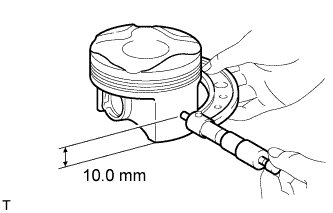

Using a micrometer, measure the piston diameter at a position that is 10.0 mm (0.394 in.) from the bottom of the piston (refer to the illustration).

- Standard piston diameter:

- 80.471 to 80.491 mm (3.168 to 3.169 in.)

|

| 4. INSPECT PISTON OIL CLEARANCE |

Subtract the piston diameter measurement from the cylinder bore diameter measurement.

- Standard oil clearance:

- 0.009 to 0.042 mm (0.000354 to 0.00165 in.)

- Maximum oil clearance:

- 0.08 mm (0.00315 in.)

| 5. INSPECT RING GROOVE CLEARANCE |

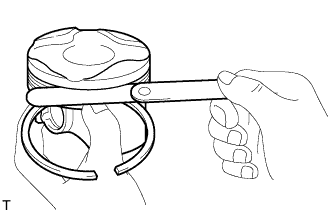

Using a feeler gauge, measure the clearance between a new piston ring and the wall of the ring groove.

- Standard Ring Groove Clearance:

Item Specified Condition No. 1 Compression Ring 0.02 to 0.07 mm (0.000787 to 0.00276 in.) No. 2 Compression Ring 0.02 to 0.06 mm (0.000787 to 0.00236 in.) Oil Ring 0.02 to 0.065 mm (0.000787 to 0.00256 in.)

|

| 6. INSPECT PISTON RING END GAP |

Using a piston, push the piston ring a little beyond the bottom of the ring travel, 50 mm (1.97 in.) from the top of the cylinder block.

|

Using a feeler gauge, measure the end gap.

- Standard End Gap:

Item Specified Condition No. 1 Compression Ring 0.20 to 0.30 mm (0.00787 to 0.0118 in.) No. 2 Compression Ring 0.30 to 0.50 mm (0.0118 to 0.0197 in.) Oil Ring 0.10 to 0.40 mm (0.00394 to 0.0157 in.)

- Maximum End Gap:

Item Specified Condition No. 1 Compression Ring 0.50 mm (0.0197 in.) No. 2 Compression Ring 0.70 mm (0.0276 in.) Oil Ring 0.70 mm (0.0276 in.)

|

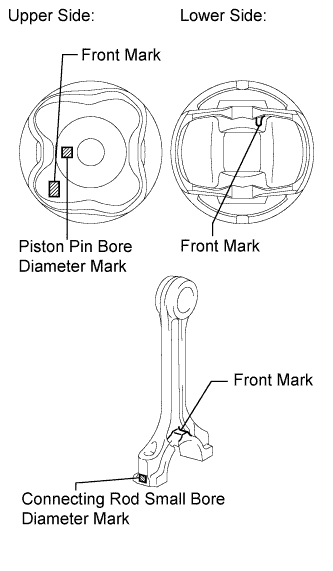

| 7. INSPECT PISTON PIN OIL CLEARANCE |

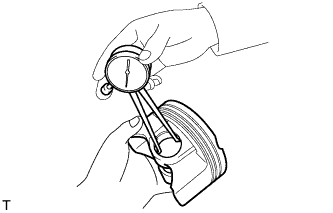

Using a caliper gauge, measure the piston pin bore diameter.

- Standard Piston Pin Bore Diameter:

Item Specified Condition Mark A 20.006 to 20.009 mm (0.78764 to 0.78775 in.) Mark B 20.010 to 20.012 mm (0.78779 to 0.78787 in.) Mark C 20.013 to 20.015 mm (0.78791 to 0.78799 in.)

|

Using a micrometer, measure the piston pin diameter.

- Standard Piston Pin Diameter:

Item Specified Condition Mark A 20.004 to 20.007 mm (0.78756 to 0.78768 in.) Mark B 20.008 to 20.010 mm (0.78771 to 0.78779 in.) Mark C 20.011 to 20.013 mm (0.78783 to 0.78791 in.)

- Measurement Position:

Measurement Position Piston Pin Position a 25 mm (0.984 in.) from side edge b 5 mm (0.197 in.) from side edge

|

Using a caliper gauge, measure the connecting rod small end bore diameter.

- Standard Connecting Rod Small End Bore Diameter:

Item Specified Condition Mark A 20.012 to 20.015 mm (0.78787 to 0.78799 in.) Mark B 20.016 to 20.018 mm (0.78803 to 0.78811 in.) Mark C 20.019 to 20.021 mm (0.78815 to 0.78823 in.)

|

Subtract the piston pin diameter measurement from the piston pin bore diameter measurement.

- Standard oil clearance:

- -0.001 to 0.005 mm (-0.0000394 to 0.000197 in.)

- Maximum oil clearance:

- 0.008 mm (0.000315 in.)

|

Subtract the piston pin diameter measurement from the connecting rod small end bore diameter measurement.

- Standard oil clearance:

- 0.005 to 0.011 mm (0.000197 to 0.000433 in.)

- Maximum oil clearance:

- 0.014 mm (0.000551 in.)

| 8. INSPECT CONNECTING ROD SUB-ASSEMBLY |

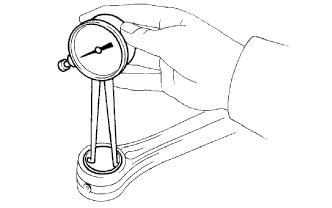

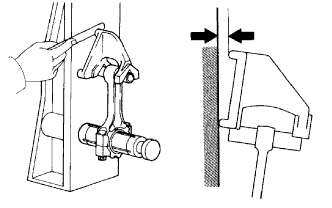

Using a connecting rod aligner and feeler gauge, check the connecting rod alignment.

Check for misalignment.

- Maximum misalignment:

- 0.05 mm (0.00197 in.) per 100 mm (3.94 in.)

Check for twist.

- Maximum twist:

- 0.15 mm (0.00591 in.) per 100 mm (3.94 in.)

|

| 9. INSPECT CRANKSHAFT |

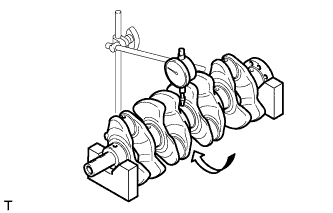

Inspect the circle runout.

Using a dial indicator and V-blocks, measure the circle runout as shown in the illustration.

- Maximum circle runout:

- 0.03 mm (0.00118 in.)

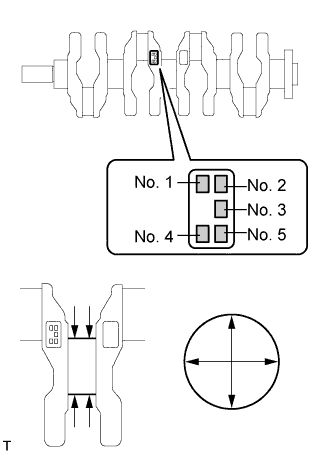

Inspect the main journals.

Using a micrometer, measure the diameter of each main journal.

- Standard diameter:

- 47.988 to 48.000 mm (1.8893 to 1.8898 in.)

Check each main journal for taper and distortion as shown in the illustration.

- Maximum taper and distortion:

- 0.004 mm (0.000157 in.)

- Standard Diameter (Reference):

Item Specified Condition Mark 0 47.999 to 48.000 mm (1.88972 to 1.88976 in.) Mark 1 47.997 to 47.998 mm (1.88964 to 1.88968 in.) Mark 2 47.995 to 47.996 mm (1.88956 to 1.88960 in.) Mark 3 47.993 to 47.994 mm (1.88948 to 1.88952 in.) Mark 4 47.991 to 47.992 mm (1.88941 to 1.88945 in.) Mark 5 47.988 to 47.990 mm (1.88929 to 1.88937 in.)

Inspect the crank pins.

Using a micrometer, measure the diameter of each crank pin.

- Standard diameter:

- 46.992 to 47.000 mm (1.8501 to 1.8505 in.)

Inspect each crank pin for taper and distortion.

- Maximum taper and distortion:

- 0.004 mm (0.000157 in.)

| 10. INSPECT CRANKSHAFT OIL CLEARANCE |

Check the crankshaft journals and bearings for pitting and scratches.

Install the crankshaft bearings (RAV4_ACA30 RM000002XA402NX_01_0007.html).

Install the upper crankshaft thrust washers (RAV4_ACA30 RM000002XA402NX_01_0009.html).

Clean each main journal and bearing.

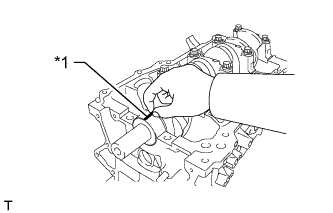

Place the crankshaft on the cylinder block.

Lay a strip of Plastigage across each journal.

Text in Illustration *1 Plastigage

|

Examine the front marks and numbers and place the bearing caps on the cylinder block.

- HINT:

- A number is marked on each crankshaft bearing cap to indicate the installation position.

Install the crankshaft bearing caps (RAV4_ACA30 RM000002XA402NX_01_0010.html).

- NOTICE:

- Do not turn the crankshaft.

Remove the crankshaft bearing caps (RAV4_ACA30 RM000002XA302MX_02_0120.html).

Measure the Plastigage at its widest point.

- Standard oil clearance:

- 0.016 to 0.039 mm (0.000630 to 0.00154 in.)

- Maximum oil clearance:

- 0.050 mm (0.00197 in.)

- NOTICE:

- Remove the Plastigage completely after the measurement.

- HINT:

- If replacing a bearing, select a new one with the same number. If the number of the bearing cannot be determined, calculate the correct bearing number by adding together the numbers imprinted on the cylinder block and crankshaft. Then select a new bearing with the calculated number according to the chart below. There are 4 sizes of standard bearings, marked "1", "2", "3" and "4" accordingly.

- Example:

Cylinder block "3" + Crankshaft "5" = Total number 8 (Use bearing "3")

Bearing Chart Cylinder Block + Crankshaft Bearing to be Used 0 to 2 "1" 3 to 5 "2" 6 to 8 "3" 9 to 11 "4" - Standard Cylinder Block Journal Bore Diameter:

Item Specified Condition Mark 0 52.000 to 52.002 mm (2.04724 to 2.04732 in.) Mark 1 52.003 to 52.004 mm (2.04736 to 2.04740 in.) Mark 2 52.005 to 52.006 mm (2.04744 to 2.04748 in.) Mark 3 52.007 to 52.009 mm (2.04752 to 2.04759 in.) Mark 4 52.010 to 52.011 mm (2.04763 to 2.04767 in.) Mark 5 52.012 to 52.013 mm (2.04771 to 2.04775 in.) Mark 6 52.014 to 52.016 mm (2.04779 to 2.04787 in.)

- Standard Crankshaft Journal Diameter:

Item Specified Condition Mark 0 47.999 to 48.000 mm (1.88972 to 1.88976 in.) Mark 1 47.997 to 47.998 mm (1.88964 to 1.88968 in.) Mark 2 47.995 to 47.996 mm (1.88956 to 1.88960 in.) Mark 3 47.993 to 47.994 mm (1.88948 to 1.88952 in.) Mark 4 47.991 to 47.992 mm (1.88941 to 1.88945 in.) Mark 5 47.988 to 47.990 mm (1.88929 to 1.88937 in.)

- Standard Bearing Center Wall Thickness:

Item Specified Condition Mark 1 1.994 to 1.997 mm (0.07850 to 0.07862 in.) Mark 2 1.998 to 2.000 mm (0.07866 to 0.07874 in.) Mark 3 2.001 to 2.003 mm (0.07878 to 0.07886 in.) Mark 4 2.004 to 2.006 mm (0.07890 to 0.07898 in.)

| 11. INSPECT CRANKSHAFT BEARING CAP BOLT |

Using a vernier caliper, measure the length of the crankshaft bearing cap bolt from the seat to the end.

- Standard length:

- 84.3 to 85.7 mm (3.32 to 3.37 in.)

- Maximum length:

- 86.7 mm (3.41 in.)

|

Using a vernier caliper, measure the diameter of the elongated thread at the measuring area.

- Distance:

- 55.0 mm (0.197 in.)

- Standard diameter:

- 9.77 to 9.96 mm (0.385 to 0.392 in.)

- Minimum diameter:

- 9.1 mm (0.358 in.)

| 12. INSPECT CONNECTING ROD BOLT |

Using a vernier caliper, measure the tension portion diameter of the bolt.

- Standard diameter:

- 6.6 to 6.7 mm (0.260 to 0.264 in.)

- Minimum diameter:

- 6.4 mm (0.252 in.)

|

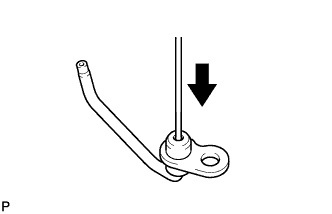

| 13. INSPECT NO. 1 OIL NOZZLE SUB-ASSEMBLY |

Push the check valve with a pin to check if it is stuck.

If stuck, replace the No. 1 oil nozzle.

|

Push the check valve with a pin to check if it moves smoothly.

If it does not move smoothly, clean or replace the No. 1 oil nozzle.

Apply air into A. Check that air does not leak through B.

If air leaks, clean or replace the No. 1 oil nozzle.

|

Push the check valve while applying air into A. Check that air passes through B.

If air does not pass through B, clean or replace the No. 1 oil nozzle.

|