Engine -- On-Vehicle Inspection |

- HINT:

- The type of ignition switch used on this model differs according to the specifications of the vehicle. For the expressions listed in this section, refer to the "Ignition Switch Expressions" precaution (RAV4_ACA30 RM000001VBG005X.html).

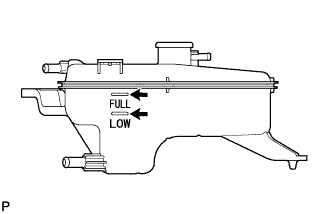

| 1. INSPECT ENGINE COOLANT |

Check that the engine coolant is between the LOW and FULL lines when the engine is cold.

If the level is low, check for leakage and add TOYOTA Super Long Life Coolant (SLLC) or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, and non-borate coolant with long-life hybrid organic acid technology up to the FULL line.

|

| 2. INSPECT ENGINE OIL |

Warm up the engine, and then stop the engine and wait for 5 minutes.

Check that the oil level is between the dipstick low level mark and full level mark.

If the level is low, check for leakage and add oil up to the full level mark.- NOTICE:

- Do not fill with engine oil above the full level mark.

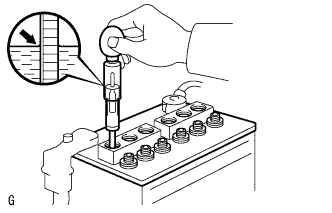

| 3. INSPECT BATTERY |

- NOTICE:

- If the battery is weak or if the engine is difficult to start, perform the following procedures.

Check the battery for damage or deformation. If severe damage, deformation or leakage is found, replace the battery.

Check the electrolyte quantity of each cell.

- HINT:

- Before checking the battery voltage, turn off all the electrical systems (headlights, blower motor, rear defogger, etc.).

For maintenance-free batteries:

- If the electrolyte quantity is below the lower line, replace the battery.

- If the electrolyte quantity is above the lower line, check the battery voltage when cranking the engine. If the voltage is below 9.6 V, recharge or replace the battery.

- If the electrolyte quantity is below the lower line, replace the battery.

For non-maintenance-free batteries:

- If the electrolyte quantity is below the lower line, add distilled water to each cell. Then, recharge the battery and check the electrolyte's specific gravity.

- Standard specific gravity:

- 1.25 to 1.29 at 20°C (68°F)

- If the electrolyte quantity is below the lower line, add distilled water to each cell. Then, recharge the battery and check the electrolyte's specific gravity.

Check the battery voltage.

Turn the engine switch off and turn on the headlights for 20 to 30 seconds. This will remove the surface charge from the battery.

Measure the battery voltage between the negative (-) and positive (+) terminals of the battery.

- Standard voltage:

- 12.5 to 12.9 V at 20°C (68°F)

| 4. INSPECT AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

Remove the air cleaner cap.

Remove the air filter element.

Visually check that the air filter is not excessively damaged or oily.

If necessary, replace the air cleaner filter element.

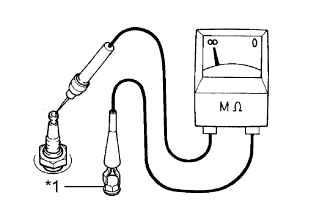

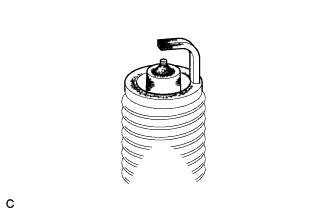

| 5. INSPECT SPARK PLUG |

- NOTICE:

- Do not use a wire brush for cleaning.

- Do not attempt to adjust the electrode gap of a used spark plug.

Check the electrode.

Using a megohmmeter, measure the insulation resistance.

- Standard resistance:

- 10 MΩ or higher

If the result is not as specified, clean the spark plug with a spark plug cleaner and measure the resistance again.Text in Illustration *1 Ground - HINT:

- If a megohmmeter is not available, perform the following simple inspection instead.

|

Alternative inspection method:

Quickly accelerate the engine to 4000 rpm 5 times.

Remove the spark plug.

Visually check the spark plug.

If the electrode is dry, the spark plug is functioning properly. If the electrode is damp, proceed to the next step.

Check the spark plug for any damage to its thread and insulator.

If there is any damage, replace the spark plug.- Recommended Spark Plug:

Manufacturer Product DENSO SC20HR11

Reference:

Check the spark plug electrode gap.

- Maximum electrode gap for used spark plug:

- 1.3 mm (0.0512 in.)

- Electrode gap for new spark plug:

- 1.0 to 1.1 mm (0.0394 to 0.0433 in.)

Clean the spark plug.

If the electrode has traces of wet carbon, clean the electrode with a spark plug cleaner and then dry it.- Air pressure:

- 588 kPa (6 kgf/cm2, 85 psi)

- Duration:

- 20 seconds or less

- HINT:

- Only use the spark plug cleaner when the electrode is free of oil. If the electrode has traces of oil, use gasoline to clean off the oil before using the spark plug cleaner.

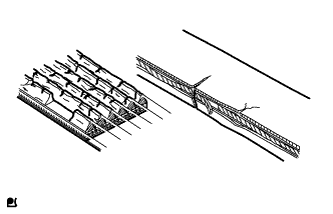

| 6. INSPECT V-RIBBED BELT |

Check the belt for wear, cracks or other signs of damage.

If any of the following defects is found, replace the V-ribbed belt.- The belt is cracked.

- The belt is worn out to the extent that the cords are exposed.

- The belt has chunks missing from the ribs.

- The belt is cracked.

|

Check that the belt fits properly in the ribbed grooves.

- HINT:

- Check with your hand to confirm that the belt has not slipped out of the grooves on the bottom to the pulley. If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt correctly.

|

Check the V-ribbed belt deflection and tension.

- Standard Deflection:

Item Specified Condition New belt 7.0 to 8.2 mm (0.276 to 0.323 in.) Used belt 7.6 to 10.0 mm (0.299 to 0.394 in.)

- Standard Tension:

Item Specified Condition New belt 700 to 800 N (70 to 80 kgf, 157.4 to 179.8 lbf) Used belt 550 to 750 N (55 to 75 kgf, 123.6 to 168.6 lbf)

- HINT:

- When inspecting the V-ribbed belt deflection, apply 98 N (10 kgf, 22.0 lbf) of tensile force to it.

- Check the V-ribbed belt deflection at the specified point.

- V-ribbed belt tension and deflection should be checked after 2 revolutions of engine cranking.

- Measure the belt tension when the engine is cold.

- When adjusting the belt, be sure to adjust it so that the tension is as close as possible to the median of the specified range.

- When replacing the belt with a new one, be sure to perform the following after adjusting the belt: idle the engine for 5 minutes, and then adjust the belt to the specified value for a new belt after the engine has cooled.

- When inspecting a belt which has been used for over 5 minutes, apply the used belt specifications.

- When using a belt tension gauge, confirm its accuracy by using a master gauge first.

|

| 7. INSPECT VALVE LASH ADJUSTER NOISE |

Rev up the engine several times. Check that the engine does not emit unusual noises.

If unusual noises occur, warm up the engine and idle it for over 30 minutes. Then perform the inspection above again.

If any defects or problems are found during the inspection above, perform a lash adjuster inspection (RAV4_ACA30 RM000002XR2015X_01_0014.html).

| 8. INSPECT IGNITION TIMING |

Warm up and stop the engine.

When using an intelligent tester:

Connect the intelligent tester to the DLC3.

Start the engine and idle it.

Turn the intelligent tester main switch on.

Enter the following menus: Powertrain / Engine and ECT / Data List / IGN Advance.

- Standard ignition timing:

- 8 to 12° BTDC @ idle

- HINT:

- Refer to the intelligent tester operator's manual for further details.

- NOTICE:

- Turn all the electrical systems and the A/C off.

- Check the ignition timing with the cooling fan off.

- When checking the ignition timing, the shift lever should be in neutral or P (for CVT).

When not using the intelligent tester:

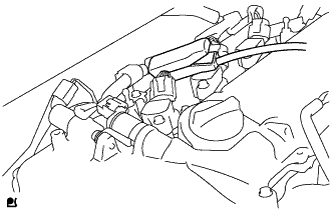

Remove the No. 2 cylinder head cover.

Connect the tester probe of a timing light to the wire of the ignition coil connector for the No. 1 cylinder.

- NOTICE:

- Use a timing light that detects primary signals.

Start the engine and idle it.

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

Text in Illustration *1 Front view of DLC3 - SST

- 09843-18040

- NOTICE:

- Confirm the terminal numbers before connecting them. Connecting the wrong terminals can damage the engine.

- When checking the ignition timing, the shift lever should be in neutral or P (for CVT).

Using the timing light, check the ignition timing.

- Standard ignition timing:

- 8 to 12° BTDC @ idle

- NOTICE:

- Turn all the electrical systems and the A/C off.

- Check the ignition timing with the cooling fan off.

- When checking the ignition timing, the shift lever should be in neutral or P (for CVT).

Remove SST from the DLC3.

Check that the ignition timing advances immediately when the engine speed is increased.

Turn the ignition switch off.

Remove the timing light.

Install the No. 2 cylinder head cover.

| 9. INSPECT ENGINE IDLE SPEED |

Warm up and stop the engine.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Engine Speed.

- Standard Idle Speed:

Item Specified Condition for Manual Transaxle 580 to 680 rpm for CVT 600 to 700 rpm

- HINT:

- Refer to the intelligent tester operator's manual for further details.

- NOTICE:

- Turn all the electrical systems and the A/C off.

- Check the ignition timing with the cooling fan off.

- When checking the idling speed, the shift lever should be in neutral or P (for CVT).

Turn the ignition switch off.

Disconnect the intelligent tester from the DLC3.

When not using the intelligent tester:

Text in Illustration *1 Front view of DLC3 Using SST, connect a tachometer probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

- NOTICE:

- Confirm the terminal numbers before connecting them. Connecting the wrong terminals can damage the engine.

- When checking the idling speed, the shift lever should be in neutral or P (for CVT).

Check the idle speed.

- Standard Idle Speed:

Item Specified Condition for Manual Transaxle 580 to 680 rpm for CVT 600 to 700 rpm

Disconnect the tachometer probe from the DLC3.

|

| 10. INSPECT COMPRESSION |

Warm up and stop the engine.

Check for DTCs (RAV4_ACA30 RM000000PDK0BLX.html).

Remove the No. 2 cylinder head cover.

Remove the 4 bolts and 4 ignition coils.

Remove the 4 spark plugs.

Disconnect the 4 fuel injector connectors.

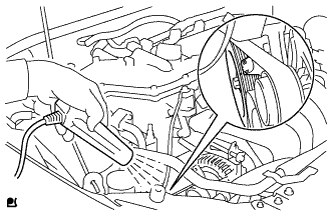

Inspect the cylinder compression pressure.

Insert a compression gauge into the spark plug hole.

Text in Illustration *1 Compression Gauge Fully open the throttle.

While cranking the engine, measure the compression pressure.

- Standard compression pressure:

- 1373 kPa (14.0 kgf/cm2, 199 psi) or higher

- Minimum pressure:

- 1079 kPa (11.0 kgf/cm2, 156 psi)

- Difference between each cylinder:

- 98 kPa (1.0 kgf/cm2, 14.2 psi) or less

- CAUTION:

- Wear protective gloves when measuring the compression to avoid injuring your hands on the outer cowl top panel.

- NOTICE:

- Use a fully-charged battery so the engine speed can be increased to 250 rpm or more.

- Inspect the other cylinders in the same way.

- Measure the compression in as short a time as possible.

If the cylinder compression is low, pour a small amount of engine oil into the cylinder through the spark plug hole, and then inspect it again.

- HINT:

- If adding oil increases the compression, the piston rings and/or cylinder bore may be worn or damaged.

- If the pressure stays low, the valve may be stuck or seated improperly, or there may be leakage from the gasket.

|

Connect the 4 fuel injector connectors.

Install the 4 spark plugs.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Install the 4 ignition coils with the 4 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the No. 2 cylinder head cover.

Clear the DTCs (RAV4_ACA30 RM000000PDK0BLX.html).

| 11. INSPECT CO/HC |

Start the engine.

Run the engine at 2500 rpm for approximately 180 seconds.

Insert the CO/HC meter testing probe at least 40 cm (1.31 ft.) into the tailpipe while idling.

Check the CO/HC concentration during idling and when the engine is running at 2500 rpm.

- HINT:

- When doing the 2 mode (with the engine idling/ running at 2500 rpm) test, the measuring procedures are determined by applicable local regulations.

- If the CO/HC concentration does not comply with the regulations, troubleshoot in the order given below.

Check the air fuel ratio sensor (RAV4_ACA30 RM000002WUP024X_01_0001.html) and heated oxygen sensor operation (RAV4_ACA30 RM000001Z1X00WX.html).

See the table below for possible causes, and then inspect the applicable parts and repair them if necessary.

CO HC Problems Possible Causes Normal High Rough idling - Faulty ignition:

- Incorrect timing

- Plugs are contaminated or shorted, or gaps are defective

- Incorrect valve clearance

- Leakage from intake or exhaust valves

- Leakage from cylinders

Low High Rough idling

(Fluctuating HC reading)- Vacuum leaks:

- PCV hoses

- Intake manifold

- Throttle body

- Brake booster line

- Lean mixture causing misfire

High High Rough idling

(Black smoke from exhaust)- Restricted air cleaner filter element

- Plugged PCV valve

- Faulty SFI system:

- Faulty pressure regulator

- Faulty engine coolant temperature sensor

- Faulty mass air flow meter

- Faulty ECM

- Faulty injectors

- Faulty throttle body

- Faulty ignition: