Engine Unit -- Replacement |

| 1. REPLACE SPARK PLUG TUBE GASKET |

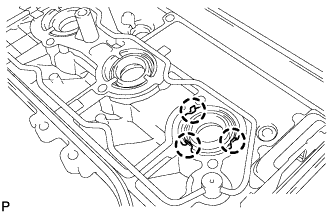

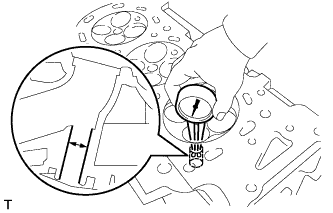

Pry up the claws of the ventilation baffle plate.

|

Using a screwdriver with its tip taped and a hammer, tap out the 6 spark plug tube gaskets.

|

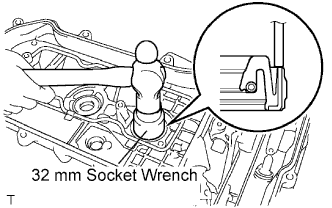

Using a 32 mm socket wrench, tap in 6 new spark plug tube gaskets to the head covers.

- NOTICE:

- Keep the lip free from foreign matter.

- Do not tap on the oil seal at an angle.

|

Return the claws of the ventilation baffle plate to its original positions.

| 2. REPLACE TIMING CHAIN COVER OIL SEAL |

Using a screwdriver, pry out the oil seal.

- HINT:

- Tape the screwdriver tip before use.

- NOTICE:

- Do not damage the surface of the oil seal press fit hole.

|

Using SST and a hammer, tap in a new oil seal until its surface is flush with the timing chain cover edge.

- SST

- 09316-60011(09316-00011)

- NOTICE:

- Keep the lip free from foreign matter.

- Do not tap the oil seal at an angle.

- Make sure that the oil seal edge does not stick out of the timing chain case.

|

Apply MP grease to the lip of the oil seal.

| 3. REPLACE ENGINE REAR OIL SEAL |

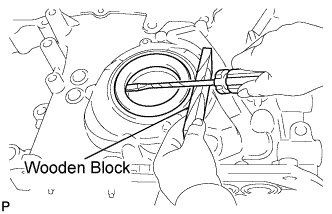

Place the oil seal retainer on wooden blocks.

|

Using a screwdriver and a hammer, tap out the oil seal.

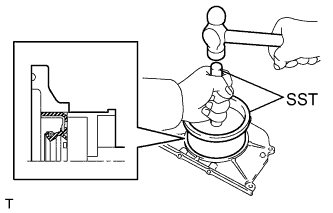

Using SST, tap in a new oil seal until its surface is flush with the oil seal retainer edge.

- SST

- 09223-15030

- NOTICE:

- Keep the lip free from foreign matter.

- Do not tap on the oil seal at an angle.

|

| 4. REPLACE INTAKE VALVE GUIDE BUSH |

Heat the cylinder head to approximately 80 to 100°C (176 to 212°F).

Place the cylinder head on wooden blocks.

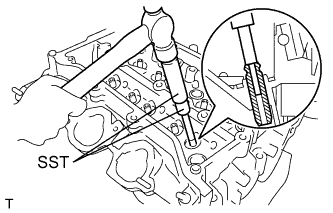

Using SST and a hammer, tap out the valve guide bush.

- SST

- 09201-10000(09201-01050)

09950-70010(09951-07100)

|

Using a caliper gauge, measure the bush bore diameter of the cylinder head.

- Standard cylinder bore diameter:

- 10.285 to 10.306 mm (0.4049 to 0.4057 in.)

|

Select a new guide bush (STD or O/S 0.05).

- Standard bush bore diameter:

Bush Size Specified Condition Use STD 10.335 to 10.356 mm (0.4069 to 0.4077 in.) Use O/S 0.05 10.285 to 10.306 mm (0.4049 to 0.4057 in.)

- HINT:

- If the bush bore diameter of the cylinder head is greater than 10.344 mm (0.4072 in.), machine the bush bore diameter to between 10.383 and 10.394 mm (0.4088 and 0.4092 in.).

- If the bush bore diameter of the cylinder head is greater than 10.344 mm (0.4072 in.), replace the cylinder head.

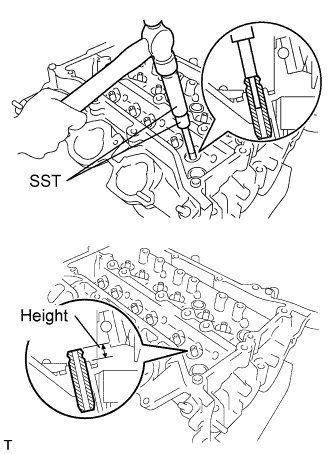

Heat the cylinder head to approximately 80 to 100°C (176 to 212°F).

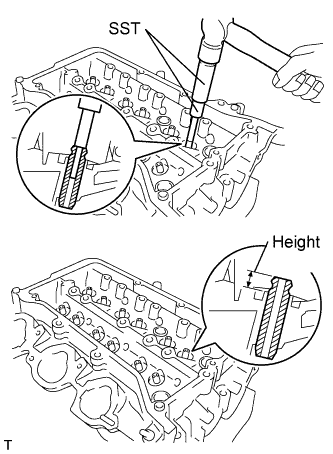

Using SST and a hammer, tap in a new guide bush to the specified protrusion height.

- Standard protrusion height:

- 9.1 to 9.9 mm (0.3582 to 0.3900 in.)

- SST

- 09201-10000(09201-01050)

09950-70010(09951-07100)

|

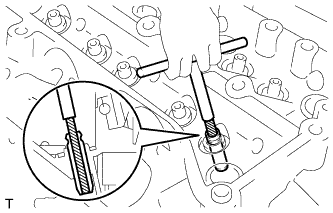

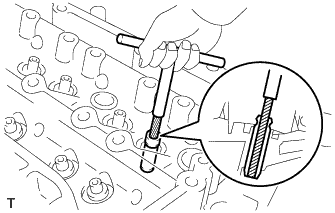

Using a sharp 5.5 mm reamer, ream the guide bush to obtain the standard specified clearance between the guide bush and valve stem.

|

| 5. REPLACE EXHAUST VALVE GUIDE BUSH |

Heat the cylinder head to approximately 80 to 100°C (176 to 212°F).

Place the cylinder head on wooden blocks.

Using SST and a hammer, tap out the valve guide bush.

- SST

- 09201-10000(09201-01050)

09950-70010(09951-07100)

|

Using a caliper gauge, measure the bush bore diameter of the cylinder head.

- Standard cylinder bore diameter:

- 10.285 to 10.306 mm (0.4049 to 0.4057 in.)

|

Select a new guide bush (STD or O/S 0.05).

- Standard bush bore diameter:

Bush Size Specified Condition Use STD 10.335 to 10.356 mm (0.4069 to 0.4077 in.) Use O/S 0.05 10.285 to 10.306 mm (0.4049 to 0.4057 in.)

- HINT:

- If the bush bore diameter of the cylinder head is greater than 10.344 mm (0.4072 in.), machine the bush bore diameter to between 10.383 and 10.394 mm (0.4088 and 0.4092 in.).

- If the bush bore diameter of the cylinder head is greater than 10.344 mm (0.4072 in.), replace the cylinder head.

Heat the cylinder head to approximately 80 to 100°C (176 to 212°F).

Using SST and a hammer, tap in a new guide bush to the specified protrusion height.

- SST

- 09201-10000(09201-01050)

09950-70010(09951-07100)

- Standard protrusion height:

- 9.30 to 9.70 mm (0.3661 to 0.3819 in.)

|

Using a sharp 5.5 mm reamer, ream the guide bush to obtain the standard specified clearance between the guide bush and valve stem.

|

| 6. REPLACE CYLINDER BLOCK STUD BOLT |

- NOTICE:

- If a stud bolt is deformed or the threads are damaged, replace it.

Remove the stud bolts.

Using an E8 "TORX" socket wrench, install the stud bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 7. REPLACE CYLINDER BLOCK STRAIGHT PIN |

- NOTICE:

- It is not necessary to remove the straight pin unless it is being replaced.

Remove the straight pin.

Using a plastic-faced hammer, tap in new straight pins to the cylinder block.

- Standard protrusion:

Item Specified Condition Pin A 23 mm (0.91 in.) Pin B 6 mm (0.24 in.) Pin C 11 mm (0.43 in.) Pin D 9 mm (0.35 in.)

| 8. REPLACE CYLINDER HEAD RING PIN |

- NOTICE:

- It is not necessary to remove the ring pin unless it is being replaced.

Remove the ring pins.

|

Using a plastic-faced hammer, tap in a new ring pin until the pin stops.

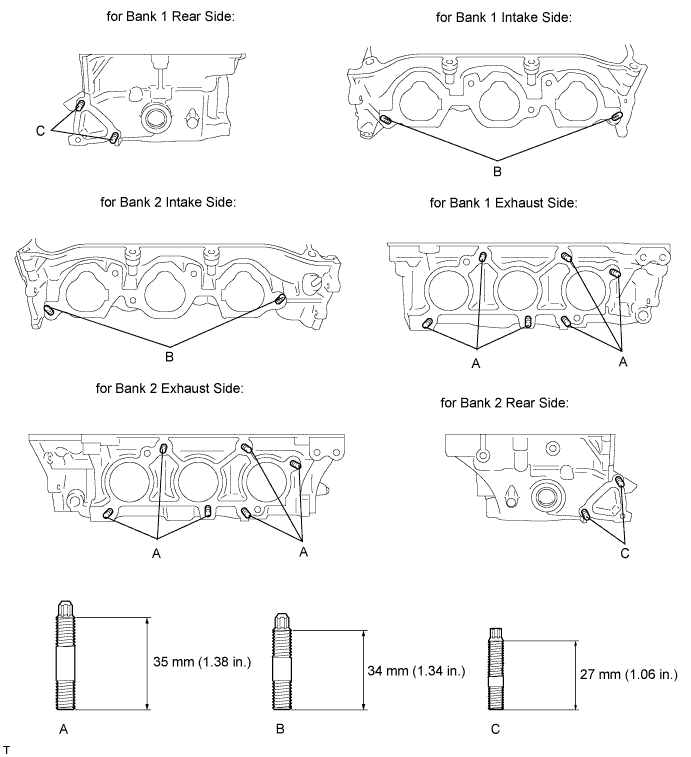

| 9. REPLACE CYLINDER HEAD STUD BOLT |

- NOTICE:

- If a stud bolt is deformed or the threads are damaged, replace it.

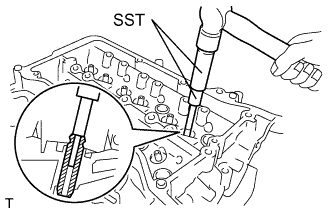

Remove the stud bolts.

Using E6 and E8 "TORX" socket wrenches, install the stud bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}for stud bolts A and B

- 4.0 N*m{41 kgf*cm, 35 in.*lbf}for stud bolt C

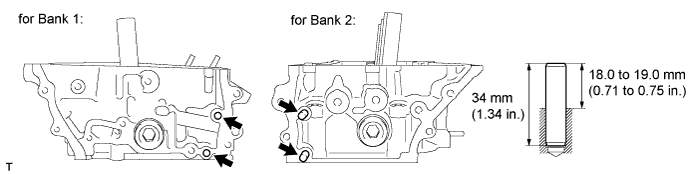

| 10. REPLACE CYLINDER HEAD SET STRAIGHT PIN |

- NOTICE:

- It is not necessary to remove the straight pin unless it is being replaced.

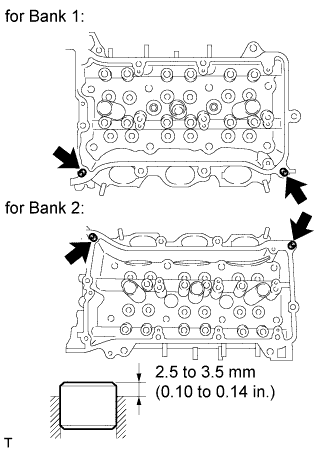

Using a plastic-faced hammer, tap in a new straight pin as shown in the illustration.

- Standard protrusion height:

- 18.0 to 19.0 mm (0.71 to 0.75 in.)