Camshaft (For Bank 2) -- Installation |

| 1. INSTALL NO. 3 CAMSHAFT |

Apply engine oil to the camshaft journals, camshaft housings and bearing caps.

Install the No. 3 camshaft to the camshaft housing.

| 2. INSTALL NO. 4 CAMSHAFT |

Apply engine oil to the camshaft journals, camshaft housings and bearing caps.

Install the No. 4 camshaft to the camshaft housing.

| 3. INSTALL CAMSHAFT BEARING CAP (for Bank 2) |

Confirm the marks and numbers on the camshaft bearing caps and place them each in their proper position and direction.

|

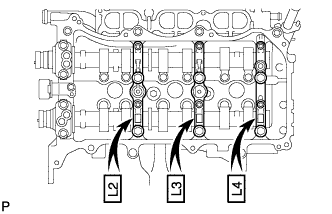

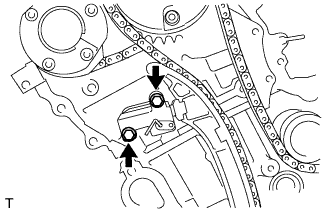

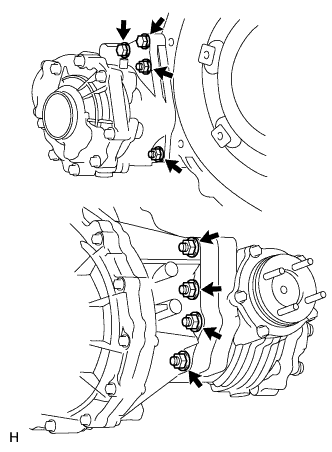

Temporarily install the 8 bolts in the order shown in the illustration.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

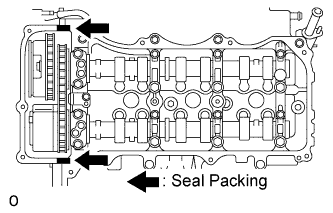

| 4. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY (for Bank 2) |

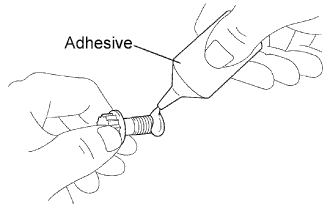

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.5 to 4.5 mm (0.138 to 0.177 in.)

- NOTICE:

- Remove any oil from the contact surface.

- Install the camshaft housing within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after the installation.

|

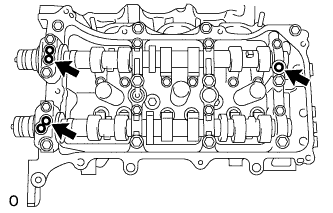

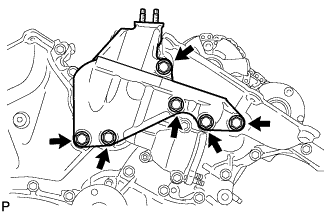

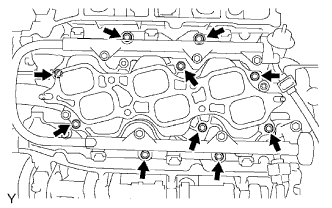

Install the camshaft housing and tighten the 13 bolts in the order shown in the illustration.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

- NOTICE:

- Make sure that the knock pin of the camshaft is positioned as shown in the illustration before installing the camshaft housing.

|

Tighten the 8 bolts in the order shown in the illustration.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

- NOTICE:

- Thoroughly wipe clean any seal packing.

|

Install 3 new gaskets.

|

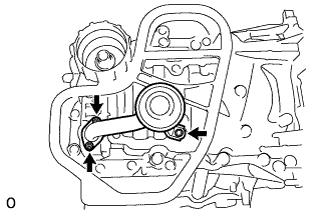

| 5. INSTALL NO. 3 CHAIN TENSIONER ASSEMBLY |

Install the chain tensioner with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

While pushing in the tensioner, insert a pin of φ1.0 mm (0.039 in.) into the hole to fix it in place.

| 6. INSTALL CAMSHAFT TIMING GEARS AND NO. 2 CHAIN (for Bank 2) |

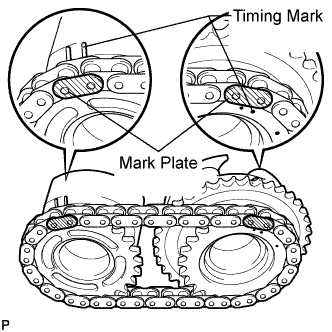

Align the mark plates (yellow) with the timing marks (2 dot mark) of the camshaft timing gears as shown in the illustration.

|

Apply a small amount of engine oil to the bolt threads and bolt-seating surface.

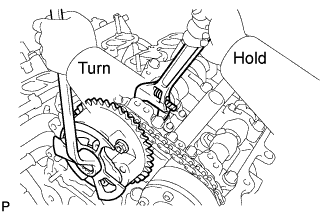

Align the knock pin of the camshaft with the pin hole of the camshaft timing gear. Install the camshaft timing gear and camshaft timing exhaust gear with the No. 2 chain installed.

Hold the hexagonal portion of the camshaft with a wrench, and tighten the 2 bolts.

- Torque:

- 100 N*m{1020 kgf*cm, 74 ft.*lbf}

|

Remove the pin from the No. 2 chain tensioner.

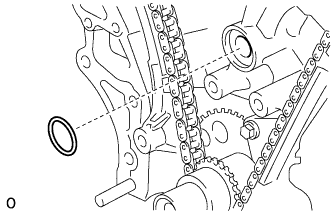

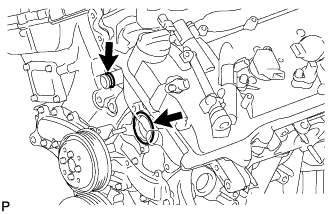

| 7. INSTALL IDLE SPROCKET ASSEMBLY |

Apply a light coat of engine oil to the rotating surface of the No. 1 idle gear shaft.

Temporarily install the No. 1 idle gear shaft and idle sprocket with the No. 2 idle gear shaft while aligning the knock pin of the No. 1 idle gear shaft with the knock pin groove of the cylinder block.

- NOTICE:

- Make sure that the idle gear is facing the correct direction.

|

Using a 10 mm hexagon wrench, tighten the No. 2 idle gear shaft.

- Torque:

- 60 N*m{612 kgf*cm, 44 ft.*lbf}

| 8. INSTALL NO. 1 CHAIN SUB-ASSEMBLY |

Align the mark plates and timing marks as shown in the illustration and install the chain.

- NOTICE:

- Do not pass the chain over the crankshaft. Rest the chain on top of the crankshaft.

- HINT:

- The chain mark plate is orange.

|

Turn the camshaft timing gear on the bank 1 counterclockwise to tighten the chain between the banks.

- NOTICE:

- If reusing the idle sprocket, align one of the idle sprocket's chain plate marks with one of the chain's chain plates when installing the idle sprocket.

|

Align the mark plate and timing mark as shown in the illustration and install the chain onto the crankshaft timing gear.

- HINT:

- The chain mark plate is yellow.

|

Temporarily tighten the pulley set bolt.

Turn the crankshaft clockwise to set it to the bank 1 block bore center line (TDC / compression).

|

| 9. INSTALL CHAIN TENSIONER SLIPPER |

Install the chain tensioner slipper.

| 10. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY |

Move the stopper plate upward to release the lock, and push the plunger deep into the tensioner.

|

Move the stopper plate downward to set the lock, and insert a hexagon wrench into the hole of the stopper plate.

Install the chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

Remove the lock pin of the chain tensioner. Check that each timing mark is aligned with the crankshaft at the TDC / compression.

|

Remove the pulley set bolt.

| 11. INSTALL TIMING CHAIN COVER OIL SEAL |

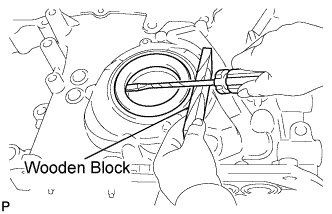

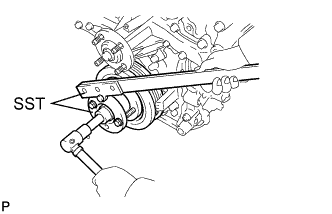

Using a screwdriver, pry out the oil seal.

- HINT:

- Tape the screwdriver tip before use.

- NOTICE:

- Do not damage the surface of the oil seal press fit hole.

|

Using SST and a hammer, tap in a new oil seal until its surface is flush with the timing chain cover edge.

- SST

- 09316-60011(09316-00011)

- NOTICE:

- Keep the lip free from foreign matter.

- Do not tap the oil seal at an angle.

- Make sure that the oil seal edge does not stick out of the timing chain case.

|

Apply MP grease to the lip of the oil seal.

| 12. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY |

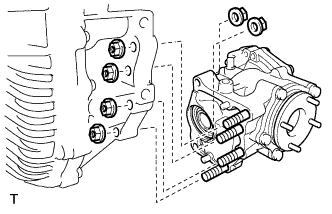

Install a new gasket.

|

Align the oil pump's drive rotor spline and the crankshaft as shown in the illustration.

|

Apply seal packing in a continuous bead to the engine unit as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Block, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.0 mm (0.118 in.) or more

- Standard length:

- 10 mm (0.394 in.)

- NOTICE:

- Be sure to clean and degrease the contact surfaces, especially the hatched areas in the illustration.

- When the contact surfaces are wet, wipe them off with an oil-free cloth before applying seal packing.

- Install the timing chain cover within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the timing chain cover.

Apply seal packing in a continuous line to the timing chain cover as shown in the illustration.

- Seal packing:

- For oil related part:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent - For water related part:

Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent

- Standard seal diameter:

Position Specified Condition A - A 6.0 mm (0.236 in.) B - B 6.5 mm (0.256 in.) Continuous line area 4.5 mm (0.177 in.) or more Dashed line area 3.5 mm (0.138 in.) or more Alternate long and short dashed line area 3.5 mm (0.138 in.) or more

- NOTICE:

- When the contact surfaces are wet, wipe them off with an oil-free cloth before applying seal packing.

- Install the timing chain cover within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the timing chain cover.

Temporarily install the timing chain cover with the 23 bolts and 2 nuts.

- NOTICE:

- Make sure that there is no oil on the bolts. If there is oil on the bolts, clean them before installing them.

- HINT:

- Bolt length:

- 40 mm (1.57 in.) for bolt A

- 55 mm (2.17 in.) for bolt B

- 25 mm (0.98 in.) for bolt C

Tighten the bolts in this order: Area 1, Area 2, Area 3, Area 4.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}for bolts in Area 1 and 2

- 21 N*m{214 kgf*cm, 15 ft.*lbf}for bolts and nuts in Area 3

- 43 N*m{438 kgf*cm, 32 ft.*lbf}for bolt A in Area 4

- 21 N*m{214 kgf*cm, 15 ft.*lbf}for bolts except A in Area 4

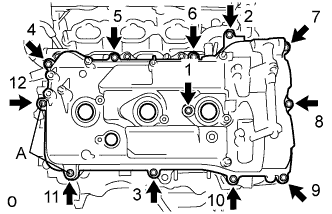

| 13. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 1) |

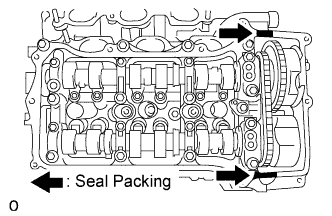

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surface.

- Install the crankcase within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after the installation.

|

Install a new gasket to the head cover.

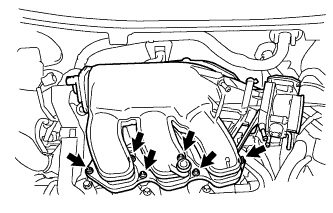

Install the head cover with the 12 bolts in the order shown in the illustration.

- Torque:

- for Bolt A:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- for except Bolt A:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

- HINT:

- Make sure the tightening torque of bolts 1 and 11 is correct.

|

| 14. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 2) |

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surface.

- Install the crankcase within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after the installation.

|

Install a new gasket to the head cover.

Install the head cover with the 12 bolts in the order in the illustration.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}for bolt A

- 10 N*m{102 kgf*cm, 7 ft.*lbf}for except bolt A

- HINT:

- Make sure the tightening torque of bolts 1 and 10 is correct.

|

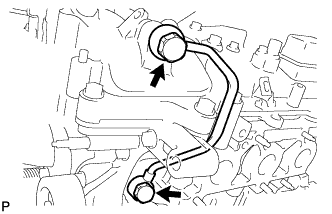

| 15. INSTALL OIL PIPE |

Make sure that there is no foreign matter on the mesh of the oil control valve filter.

|

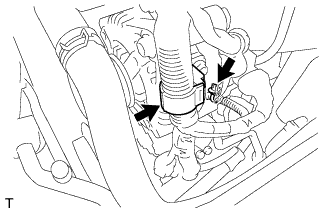

Install the oil control valve filter to the oil pipe union. Install 2 new gaskets and temporarily install the oil pipe (on the head cover side) with the oil pipe union.

- NOTICE:

- Remove any oil from the contact surface.

Install a new gasket and temporarily install the oil pipe (on the cylinder head side) with the oil pipe union.

- NOTICE:

- Remove any oil from the contact surface.

Install bolt A to the cylinder head.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Tighten the 2 oil pipe union bolts.

- Torque:

- 65 N*m{663 kgf*cm, 48 ft.*lbf}

| 16. INSTALL NO. 1 OIL PIPE |

Make sure that there is no foreign matter on the mesh of the oil control valve filter.

|

Install the oil control valve filter to the oil pipe union. Install 2 new gaskets and temporarily install the oil pipe (on the head cover side) with the oil pipe union.

Install a new gasket and temporarily install the oil pipe (on the cylinder head side) with the oil pipe union.

- NOTICE:

- Remove any oil from the contract surface.

Tighten the 2 oil pipe union bolts.

- Torque:

- 65 N*m{663 kgf*cm, 48 ft.*lbf}

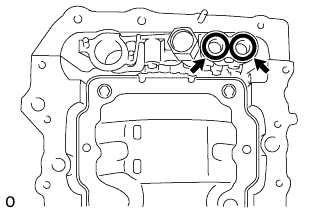

| 17. INSTALL OIL PAN SUB-ASSEMBLY |

Install 2 new O-rings to the timing chain cover.

|

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.0 to 4.0 mm (0.118 to 0.156 in.)

- NOTICE:

- Remove any oil from the contact surface.

- Install the oil pan within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the oil pan.

|

Install the oil pan with the 16 bolts and 2 nuts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}for bolt A

- 21 N*m{214 kgf*cm, 15 ft.*lbf}for bolts except A and nuts

|

| 18. INSTALL OIL STRAINER SUB-ASSEMBLY |

Install a new gasket and the oil strainer with the bolt and 2 nuts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

| 19. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY |

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.0 to 4.0 mm (0.118 to 0.156 in.)

- NOTICE:

- Remove any oil from the contact surface.

- Install the oil pan within 3 minutes and tighten the bolts within 10 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the oil pan.

|

Install the oil pan with the 16 bolts and 2 nuts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

Install a new gasket and the drain plug.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

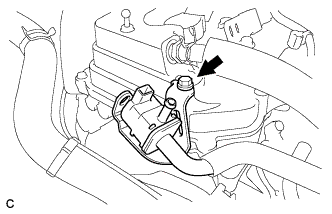

| 20. INSTALL WATER INLET HOUSING |

Install a new water inlet housing No. 1 gasket and water outlet pipe O-ring.

|

Install the water inlet housing with the 2 bolts and nut.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

- NOTICE:

- Be careful not to allow the O-ring to get caught between the parts.

|

Connect the water hose.

| 21. INSTALL CRANKSHAFT PULLEY |

Align the pulley set key with the key groove of the pulley, and slide on the pulley.

|

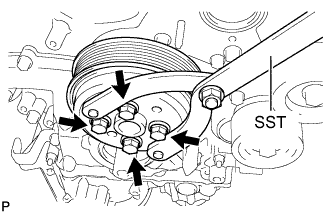

Using SST, install the pulley bolt.

- SST

- 09213-70011(09213-70020)

09330-00021

- Torque:

- 250 N*m{2549 kgf*cm, 184 ft.*lbf}

| 22. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY |

Install the No. 1 vacuum switching valve with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7.4 ft.*lbf}

|

| 23. INSTALL RADIO SETTING CONDENSER |

Install the 2 radio setting condensers with the 2 bolts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

|

| 24. INSTALL FRONT NO. 1 ENGINE MOUNTING BRACKET |

Install the engine mounting bracket with the 6 bolts.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

- NOTICE:

- Install the water inlet and mounting bracket within 15 minutes after installing the chain cover.

- Do not start the engine for at least 2 hours after the installation.

|

| 25. INSTALL WATER PUMP PULLEY |

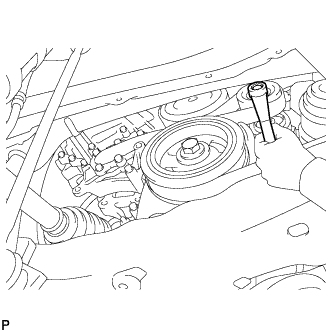

Temporarily install the water pump pulley with the 4 bolts.

|

Using SST, hold the water pump pulley.

- SST

- 09960-10010(09962-01000,09963-00700)

Tighten the 4 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 26. INSTALL NO. 2 TIMING GEAR COVER |

Install the gear cover with the 2 bolts.

- Torque:

- 6.0 N*m{61 kgf*cm, 53 in.*lbf}

| 27. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY |

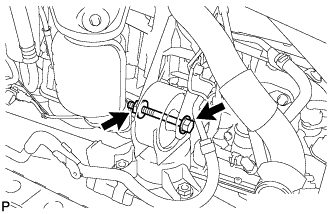

Temporarily install the V-ribbed belt tensioner with the 5 bolts.

|

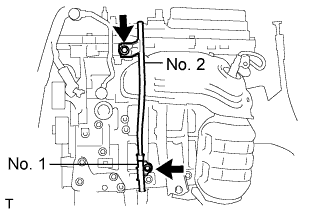

Install the V-ribbed belt tensioner by tightening the bolt 1 and bolt 2 in the order shown in the illustration.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

Tighten the other bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

Each bolt length is as follows: A 70 mm (2.76 in.) B 35 mm (1.37 in.)

| 28. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH |

Install a new gasket as shown in the illustration.

|

Install the manifold with the 6 nuts in the order shown in the illustration.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

| 29. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR |

Install the No. 2 heat insulator with the 3 bolts.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

| 30. INSTALL NO. 2 MANIFOLD STAY |

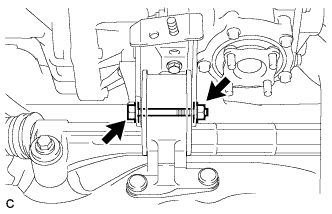

Install the No. 2 manifold stay with the bolt and nut in the order shown in the illustration.

- Torque:

- 34 N*m{347 kgf*cm, 25 ft.*lbf}

|

| 31. INSTALL OIL DIPSTICK GUIDE |

Install 2 new O-rings to the guide.

|

Apply a light coat of engine oil to the O-rings.

Push in the guide end into the guide hole.

Install the No. 1 guide with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Install the No. 2 guide with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Install the dipstick.

| 32. INSTALL GENERATOR ASSEMBLY |

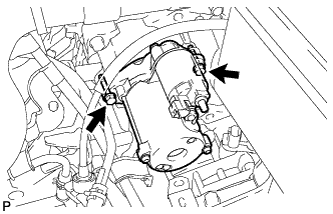

Install the generator with the 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

|

Install the bolt to the cylinder block.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

|

Connect the generator connector to the generator.

|

Connect the generator wire with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 88 in.*lbf}

Install the terminal cap.

Connect the 2 wire harness clamps.

|

| 33. INSTALL COOLER COMPRESSOR ASSEMBLY |

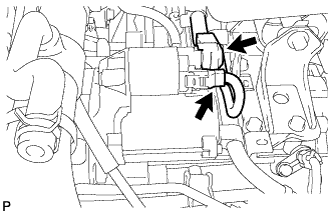

Install the cooler compressor with the 4 bolts.

- Torque:

- 24.5 N*m{250 kgf*cm, 18 ft.*lbf}

- NOTICE:

- Tighten the bolts in the order shown in the illustration to install the cooler compressor.

|

Connect the connector.

| 34. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY |

Install the idler pulley cover plate, idler pulley, No. 2 idler pulley cover plate with the bolt.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

|

| 35. INSTALL V-RIBBED BELT |

Rotate the tensioner pulley counterclockwise, and then install the V-ribbed belt.

|

If it is difficult to install the V-ribbed belt, perform the following procedure.

Put the V-ribbed belt on everything except the tensioner pulley as shown in the illustration.

While releasing the belt tension by turning the belt tensioner counterclockwise, put the V-ribbed belt on the tensioner pulley.

- NOTICE:

- Put the backside of the V-ribbed belt on the tensioner pulley and idler pulley.

- Check that the V-ribbed belt is properly set to each pulley.

|

| 36. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH |

Install a new gasket as shown in the illustration.

|

Install the manifold with the 6 nuts in the order shown in the illustration.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

| 37. INSTALL MANIFOLD STAY |

Install the manifold stay with the 2 bolts and nut in the order shown in the illustration.

- Torque:

- 34 N*m{347 kgf*cm, 25 ft.*lbf}

|

| 38. INSTALL INTAKE MANIFOLD |

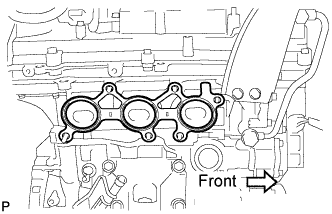

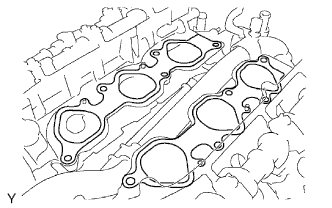

Set a new gasket on each cylinder head.

- NOTICE:

- Align the port holes of the gasket and cylinder head.

- Be careful of the installation direction.

|

Set the intake manifold on the cylinder heads.

Install and uniformly tighten the 6 bolts and 4 nuts in several passes.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

Connect the 6 fuel injector connectors.

| 39. INSTALL NO. 2 ENGINE MOUNTING STAY RH |

Install the mounting stay with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 40. INSTALL IGNITION COIL ASSEMBLY |

Install the 6 ignition coils to the cylinder head with the 6 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 41. INSTALL INTAKE AIR SURGE TANK ASSEMBLY |

- NOTICE:

- DO NOT apply oil to the bolts listed below: :

Tightening Parts Surge Tank and Intake Manifold No. 1 Surge Tank Stay and Cylinder Head Cover No. 1 Surge Tank Stay and Surge Tank Throttle Body Bracket and Cylinder Head Cover Throttle Body Bracket and Surge Tank

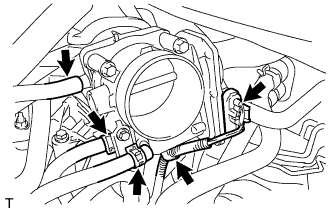

Install a new gasket to the surge tank.

Using a 5 mm hexagon socket wrench, install the 4 bolts and 2 nuts.

- Torque:

- Bolt:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

- Nut:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

|

Install the throttle body bracket and No. 1 surge tank stay with the 4 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

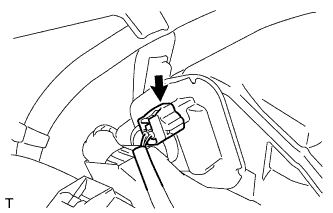

Connect the connector.

|

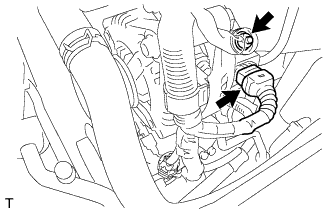

Connect the No. 1 ventilation hose and vacuum hose.

Install the clamp and connect the throttle body connector.

|

Connect the vapor feed hose.

Connect the 2 water by-pass hoses to the throttle body.

| 42. REMOVE ENGINE FROM ENGINE STAND |

Install a sling device and chain block to the engine.

Remove the engine from the engine stand.

| 43. INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY |

Clean the bolt and its hole.

|

Apply adhesive to 2 or 3 threads of the bolt end.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Using SST, hold the crankshaft.

- SST

- 09213-70011(09213-70020)

09330-00021

|

Install the flywheel, drive plate and drive plate spacer on the crankshaft.

Uniformly install and tighten the 8 bolts in the sequence shown in the illustration.

- Torque:

- 83 N*m{847 kgf*cm, 61 ft.*lbf}

- NOTICE:

- Do not start the engine for at least 1 hour after the installation.

|

| 44. INSTALL TRANSFER ASSEMBLY |

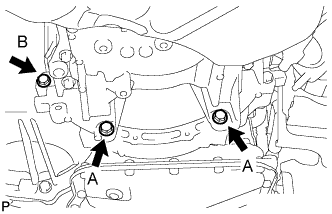

except K111F:

Install the transfer to the transaxle with the 6 nuts and 2 bolts.- Torque:

- 69 N*m{700 kgf*cm, 51 ft.*lbf}

|

for K111F:

Install the transfer to the transaxle with the 6 nuts and 2 bolts.- Torque:

- 69 N*m{700 kgf*cm, 51 ft.*lbf}

|

| 45. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY |

Install the automatic transaxle to the engine with the 7 upper side mounting bolts.

- Torque:

- 64 N*m{653 kgf*cm, 47 ft.*lbf}

- NOTICE:

- Make sure that the 2 knock pins are installed on the engine before installing the transaxle.

|

Install the 3 lower side mounting bolts.

- Torque:

- Bolt A:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

- Bolt B:

- 46 N*m{469 kgf*cm, 34 ft.*lbf}

|

Install the 6 torque converter clutch mounting bolts.

- Torque:

- 41 N*m{418 kgf*cm, 30 ft.*lbf}

- HINT:

- First install the black colored bolt and then the other 5 bolts.

|

Install the flywheel housing under cover with the 2 bolts.

- Torque:

- 7.8 N*m{80 kgf*cm, 69 in.*lbf}

|

| 46. INSTALL STARTER ASSEMBLY |

Install the starter with the 2 bolts.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

|

Connect the starter connector.

|

Install the terminal nut and cover the nut with the cap.

- Torque:

- 9.8 N*m{100 kgf*cm, 88 in.*lbf}

| 47. INSTALL ENGINE WIRE |

Install the engine wire to the engine.

| 48. INSTALL FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY |

Attach the engine together with the transaxle to the suspension crossmember and mounting.

Install the bolt which secures the engine mounting bracket to the mounting insulator.

- Torque:

- 95 N*m{969 kgf*cm, 70 ft.*lbf}

|

| 49. INSTALL FRONT CROSS MEMBER SUB-ASSEMBLY |

Install the bolt and nut which secure the engine mounting bracket to the mounting insulator.

- Torque:

- 145 N*m{1478 kgf*cm, 107 ft.*lbf}

|

| 50. INSTALL ENGINE WITH TRANSAXLE |

Install the engine with transaxle (RAV4_ACA30 RM0000019Y7015X.html).