Continuously Variable Valve Lift Controller Installation

Engine. Toyota Rav4. Aca30, 33, 38 Gsa33 Zsa30, 35

INSTALL CONTINUOUSLY VARIABLE VALVE LIFT CONTROLLER ASSEMBLY

INSTALL CYLINDER HEAD COVER GASKET

INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

INSTALL AIR TUBE

INSTALL IGNITION COIL ASSEMBLY

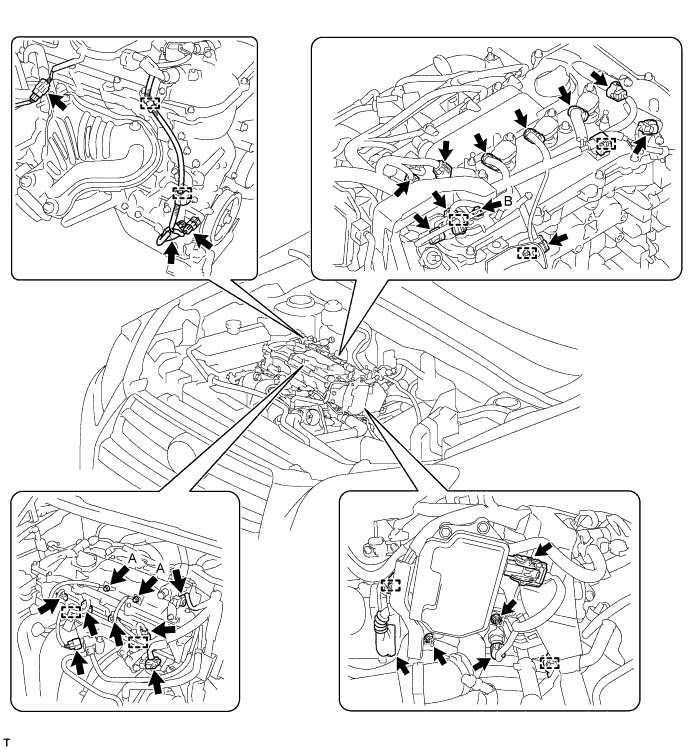

CONNECT ENGINE WIRE

INSTALL BATTERY TRAY

INSTALL BATTERY

INSTALL BATTERY CLAMP SUB-ASSEMBLY

INSTALL AIR CLEANER CASE SUB-ASSEMBLY

INSTALL AIR CLEANER CAP SUB-ASSEMBLY

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

INSTALL NO. 2 CYLINDER HEAD COVER

INSTALL RADIATOR SUPPORT OPENING COVER

Continuously Variable Valve Lift Controller -- Installation |

| 1. INSTALL CONTINUOUSLY VARIABLE VALVE LIFT CONTROLLER ASSEMBLY |

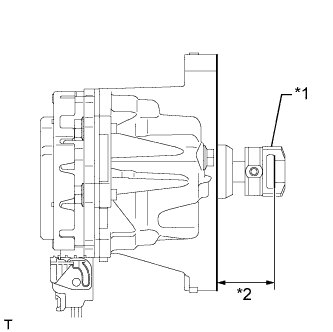

Measure the protruding distance of the continuously variable valve lift controller assembly.

Text in Illustration*1

| Connector

|

*2

| Protruding Distance

|

- HINT:

- When reinstalling the continuously variable valve lift controller assembly, perform the measurement after the valve lift control actuator connector is installed.

- It is not necessary to perform this measurement when installing a new continuously variable valve lift controller assembly as the protruding distance is 34.57 to 34.73 mm (1.36 to 1.37 in.).

- Standard protruding distance:

- 34.57 to 34.73 mm (1.36 to 1.37 in.)

If the protruding distance of the continuously variable valve lift controller assembly is not 34.57 to 34.73 mm (1.36 to 1.37 in.), perform the Active Test and adjust the protruding distance to the specified value (RAV4_ACA30 RM0000037CZ008X_01_0001.html).

Install a new O-ring to the continuously variable valve lift controller assembly.

- NOTICE:

- Align the protrusion of the O-ring with the protrusion of the continuously variable valve lift controller assembly.

- Make sure that the O-ring is not protruding from the groove in the continuously variable valve lift controller assembly.

Text in Illustration*1

| Protrusion

|

*2

| New O-Ring

|

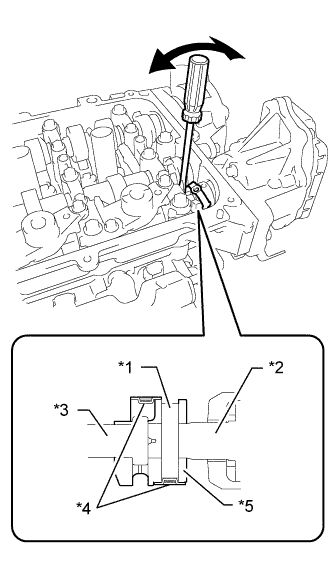

Rotate the crankshaft clockwise to retract the valve rocker shaft.

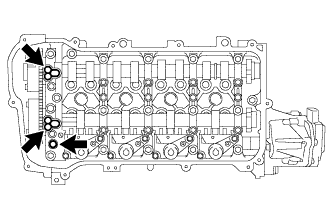

Rotate the crankshaft clockwise again until the intake camshaft position at the No. 1 cylinder and No. 3 cylinder is as shown in the illustration.

Install the valve lift control actuator connector clip to the valve lift control actuator connector.

- NOTICE:

- Be sure to insert the protrusions of the valve lift control actuator connector clip into the holes in the valve lift control actuator connector.

- HINT:

- When the continuously variable valve lift controller assembly is new, a valve lift control actuator connector is attached to it. Remove the valve lift control actuator connector before performing these procedures.

Install the valve lift control actuator connector to the valve rocker shaft and rotate the valve lift control actuator connector as shown in the illustration.

Insert the continuously variable valve lift controller assembly into the camshaft housing.

Place the wire harness clamp bracket onto the stud bolts.

Install the continuously variable valve lift controller assembly to the camshaft housing with the bolt and 2 nuts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

- NOTICE:

- Make sure the O-ring is not caught between the parts.

Using a screwdriver, slide the valve lift control actuator connector clip from the valve lift control actuator connector.

- NOTICE:

- Slide only the upper part of the valve lift control actuator connector clip as the straight pin falls out from the bottom if the valve lift control actuator connector clip is completely removed.

Using a screwdriver, lightly pry the valve lift control actuator connector and align the hole in the valve lift control actuator connector with the hole in the continuously variable valve lift controller assembly.

- NOTICE:

- Do not forcefully pry the valve lift control actuator connector.

- Do not damage the camshaft housing or camshaft bearing cap.

Text in Illustration*1

| Straight Pin

|

*2

| Controller Shaft

|

*3

| Rocker Shaft

|

*4

| Clip

|

*5

| Connector

|

Insert the straight pin into the valve lift control actuator connector.

- NOTICE:

- Do not use a tool to insert the straight pin. Insert the straight pin by hand.

- HINT:

- If the straight pin is difficult to insert, insert the pin while lightly prying the valve lift control actuator connector.

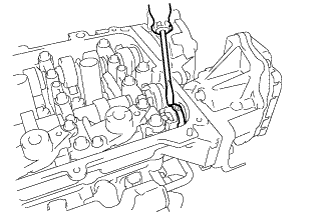

Using a screwdriver, install the valve lift control actuator connector clip to the valve lift control actuator connector.

- NOTICE:

- Insert the protrusion of the valve lift control actuator connector clip into the hole in the valve lift control actuator connector.

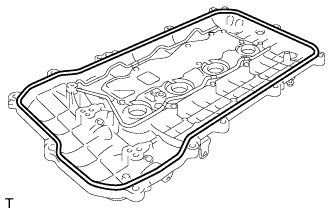

| 2. INSTALL CYLINDER HEAD COVER GASKET |

Install a new cylinder head cover gasket to the cylinder head cover.

- NOTICE:

- Remove any oil from the contact surfaces.

| 3. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

Install 3 new gaskets to the camshaft bearing cap.

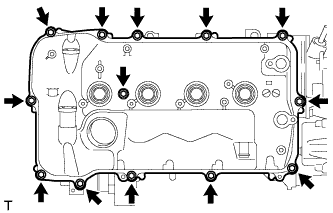

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard diameter:

- 4.0 mm (0.157 in.)

- NOTICE:

- Remove any oil from the contact surfaces.

- Install the cylinder head cover sub-assembly within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after the installation.

Install the cylinder head cover with a new seal washer and the 13 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

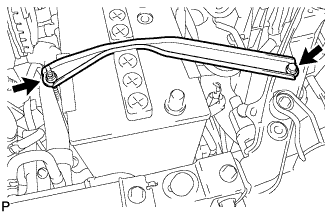

Install the air tube with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the No. 2 air hose and No. 1 fuel vapor feed hose.

Connect the 2 union to connector tube hoses.

Connect the fuel vapor feed hose to the purge VSV.

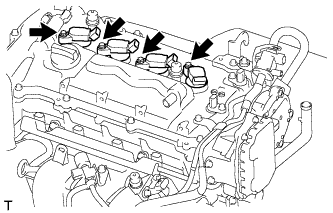

| 5. INSTALL IGNITION COIL ASSEMBLY |

Install the 4 ignition coils with the 4 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

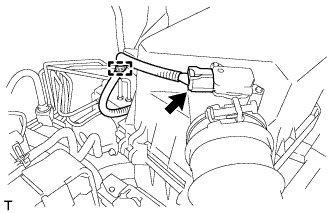

Attach the 9 clamps, and then connect the connectors.

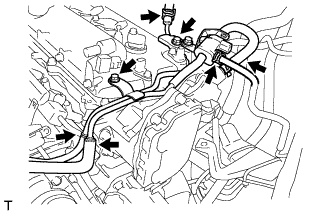

Connect the engine wire with the 3 bolts and 2 nuts.

- Torque:

- for bolt A:

- 8.4 N*m{85 kgf*cm, 74 in.*lbf}

- for bolt B:

- 7.7 N*m{78 kgf*cm, 68 in.*lbf}

- for nut:

- 7.7 N*m{78 kgf*cm, 68 in.*lbf}

| 9. INSTALL BATTERY CLAMP SUB-ASSEMBLY |

Attach the hook of the battery clamp to the front battery bracket.

Partially tighten the nut and temporarily install the bolt.

Adjust the battery clamp position.

Tighten the nut and bolt.

- Torque:

- for bolt:

- 17 N*m{168 kgf*cm, 12 ft.*lbf}

- for nut:

- 4.9 N*m{50 kgf*cm, 43 in.*lbf}

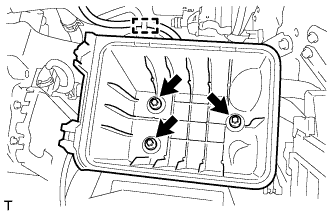

| 10. INSTALL AIR CLEANER CASE SUB-ASSEMBLY |

Install the air cleaner case with the 3 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Attach the wire harness clamp to the air cleaner case.

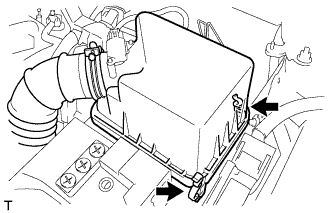

| 11. INSTALL AIR CLEANER CAP SUB-ASSEMBLY |

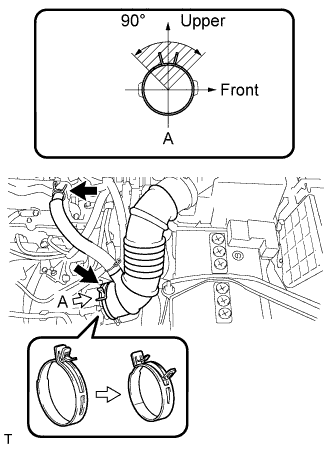

Insert the hinge part of the air cleaner cap and hose into the air cleaner case, and then fasten the 2 hook clamps.

Connect the No. 1 air cleaner hose to the throttle body and push apart the tabs of the No. 1 air cleaner hose clamp.

- HINT:

- The direction of the hose clamp is indicated in the illustration.

Connect the No. 2 ventilation hose to the cylinder head cover.

Attach the clamp.

Connect the mass air flow meter connector.

| 12. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

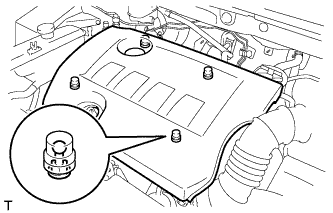

| 13. INSTALL NO. 2 CYLINDER HEAD COVER |

Attach the 4 clips to install the cover.

- NOTICE:

- Be sure to attach the clips securely.

- Do not apply excessive force or do not hit the cover to attach the clips. This may cause the cover to break.

| 14. INSTALL RADIATOR SUPPORT OPENING COVER |

Install the radiator support opening cover with the 9 clips.