Compressor And Magnetic Clutch (For 5L-E) -- Reassembly |

| 1. INSTALL MAGNETIC CLUTCH ASSEMBLY |

Please the compressor and magnetic clutch in a vise.

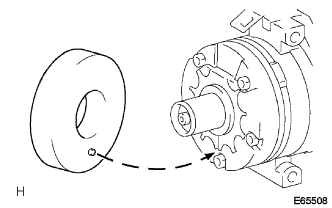

Install the magnet clutch starter with the parts shown in the illustration matched.

|

Using a snap ring expander, install a new snap ring with the chamfered side facing up.

- NOTICE:

- Take care not to damage the seal cover of the bearing when installing the snap ring.

|

Connect the connector.

Using a snap ring expander, install the magnet clutch rotor and a new snap ring with the chamfered side facing up.

- NOTICE:

- Do not expand the snap ring by more than 30.5 mm (1.20 in.) when installing it.

- Do not damage the seal cover of the bearing when installing the snap ring.

|

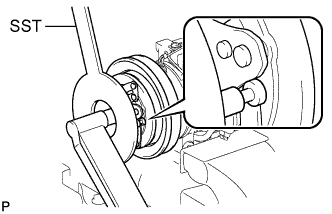

Install the magnet clutch washer and magnet clutch hub.

- NOTICE:

- Do not change the combination of the magnet clutch washer used before disassembly.

Using SST, install the magnet clutch hub and the magnet clutch washer with the bolt.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

- NOTICE:

- Make sure that there is no foreign matter or oil on the compressor shaft, bolt, and clutch hub.

|

| 2. INSPECT MAGNETIC CLUTCH CLEARANCE |

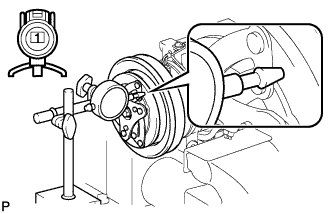

Set the dial indicator to the magnet clutch hub.

|

Connect the battery positive lead to terminal 1 of the magnet clutch connector and the negative lead to the ground wire. Turn the magnet clutch on and off and measure the clearance.

- Standard clearance:

- 0.35 to 0.60 mm (0.013 to 0.024 in.)

- NOTICE:

- Adjustment should be performed with 3 or less magnet clutch washers.

| 3. ADJUST COMPRESSOR OIL |

When replacing the compressor and magnetic clutch with a new one, gradually discharge the refrigerant gas from the service valve, and drain the following amount of oil from the new compressor and magnetic clutch before installation.

- Standard:

- (Oil capacity inside the new compressor and magnetic clutch: 80 + 15 cc (2.7 + 0.5 fl. oz.)) - (Remaining oil amount in the removed compressor and magnetic clutch) = (Oil amount to be removed from the new compressor when replacing)

- NOTICE:

- When checking the compressor oil level, observe the precautions on the cooler removal/installation.

- If a new compressor and magnetic clutch installed without removing some oil remaining in the pipes of the vehicle, the oil amount will be too large. This prevents heat exchange in the refrigerant cycle and causes refrigerant failure.

- If the volume of oil remaining in the removed compressor and magnetic clutch is too small, check for oil leakage.

- Be sure to use ND-OIL 8 for compressor oil.