Steering Linkage Installation

INSTALL POWER STEERING LINK ASSEMBLY

INSTALL FRONT STABILIZER BAR FRONT

STABILIZE SUSPENSION

CONNECT STEERING GEAR OUTLET RETURN TUBE

CONNECT PRESSURE FEED TUBE ASSEMBLY

FULLY TIGHTEN NO. 2 STEERING INTERMEDIATE SHAFT SUB-ASSEMBLY

CONNECT TIE ROD END SUB-ASSEMBLY LH

CONNECT TIE ROD END SUB-ASSEMBLY RH

INSTALL FRONT SIDE MEMBER TO FRONT SUSPENSION CROSSMEMBER BRACE

INSTALL NO. 1 ENGINE UNDER COVER

INSTALL NO. 2 ENGINE UNDER COVER

INSTALL FRONT WHEEL

PLACE FRONT WHEELS FACING STRAIGHT AHEAD

INSTALL WINDSHIELD WIPER SWITCH ASSEMBLY

INSTALL HEADLIGHT DIMMER SWITCH ASSEMBLY

INSTALL SPIRAL CABLE SUB-ASSEMBLY

INSTALL STEERING COLUMN COVER UPPER

INSTALL STEERING COLUMN COVER LOWER

INSTALL STEERING WHEEL ASSEMBLY

INSPECT STEERING WHEEL CENTER POINT

INSTALL STEERING PAD ASSEMBLY

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

INSPECT SRS WARNING LIGHT

ADD POWER STEERING FLUID

BLEED AIR FROM POWER STEERING SYSTEM

CHECK POWER STEERING FLUID LEVEL IN RESERVOIR

CHECK FOR POWER STEERING FLUID LEAKAGE

INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

Steering Linkage -- Installation |

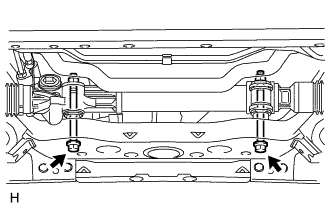

| 1. INSTALL POWER STEERING LINK ASSEMBLY |

Install the steering link with the 2 bolts and 2 nuts.

- Torque:

- 95 N*m{969 kgf*cm, 70 ft.*lbf}

- HINT:

- If necessary, return the differential to its original position and install the differential mount.

| 2. INSTALL FRONT STABILIZER BAR FRONT |

Install the front stabilizer bar to the vehicle body.

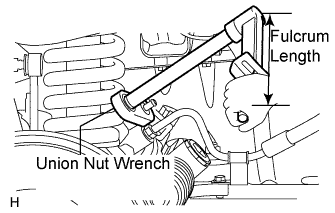

| 4. CONNECT STEERING GEAR OUTLET RETURN TUBE |

Using union nut wrench, connect the outlet return tube.

- Torque:

- 44 N*m{449 kgf*cm, 33 ft.*lbf}for use without union nut wrench

- 40 N*m{409 kgf*cm, 30 ft.*lbf}for use with union nut wrench

- HINT:

- Use a torque wrench with a fulcrum length of 300 mm (11.81 in.).

- This torque value is effective when union nut wrench is parallel to the torque wrench.

Install the hose with the clip.

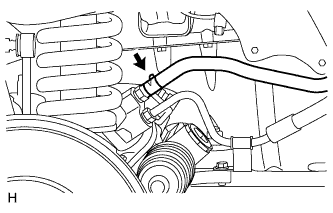

| 5. CONNECT PRESSURE FEED TUBE ASSEMBLY |

Install the pressure feed tube to the steering link with the bolt.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

Using union nut wrench, tighten the flare nut and connect the pressure feed tube.

- Torque:

- 44 N*m{449 kgf*cm, 33 ft.*lbf}for use without union nut wrench

- 40 N*m{409 kgf*cm, 30 ft.*lbf}for use with union nut wrench

- HINT:

- Use a torque wrench with a fulcrum length of 300 mm (11.81 in.).

- This torque value is effective when union nut wrench is parallel to the torque wrench.

| 6. FULLY TIGHTEN NO. 2 STEERING INTERMEDIATE SHAFT SUB-ASSEMBLY |

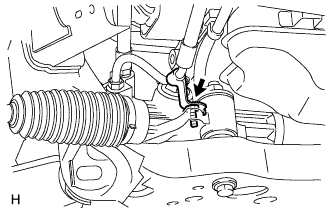

| 7. CONNECT TIE ROD END SUB-ASSEMBLY LH |

Connect the tie rod end to the steering knuckle arm with the nut.

- Torque:

- 91 N*m{928 kgf*cm, 67 ft.*lbf}

Install a new cotter pin.

| 8. CONNECT TIE ROD END SUB-ASSEMBLY RH |

- HINT:

- Use the same procedures described for the LH side.

| 9. INSTALL FRONT SIDE MEMBER TO FRONT SUSPENSION CROSSMEMBER BRACE |

Install the crossmember brace with the 8 bolts.

- Torque:

- 50 N*m{510 kgf*cm, 37 ft.*lbf}

| 10. INSTALL NO. 1 ENGINE UNDER COVER |

Install the under cover with the 4 bolts.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 11. INSTALL NO. 2 ENGINE UNDER COVER |

Install the under cover with the 4 bolts.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 13. PLACE FRONT WHEELS FACING STRAIGHT AHEAD |

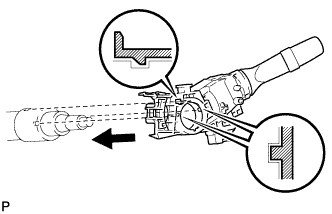

| 14. INSTALL WINDSHIELD WIPER SWITCH ASSEMBLY |

Attach the claw to install the windshield wiper switch.

- NOTICE:

- Do not push the claw with excessive force as damage may occur.

Connect the connectors.

| 15. INSTALL HEADLIGHT DIMMER SWITCH ASSEMBLY |

Install the headlight dimmer switch with the claw as shown in the illustration.

Install the headlight dimmer switch with the clamp.

Connect the connector.

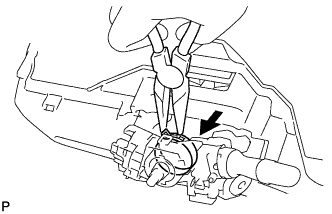

| 16. INSTALL SPIRAL CABLE SUB-ASSEMBLY |

| 17. INSTALL STEERING COLUMN COVER UPPER |

| 18. INSTALL STEERING COLUMN COVER LOWER |

Install the steering column with the 3 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Install the cover with the 3 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

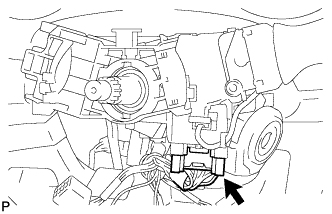

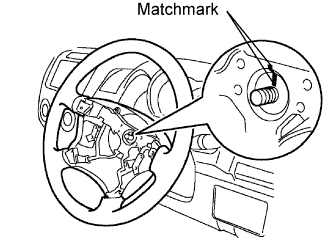

| 19. INSTALL STEERING WHEEL ASSEMBLY |

Align the matchmarks on the steering wheel and main shaft.

Install the steering set nut.

- Torque:

- 50 N*m{510 kgf*cm, 37 ft.*lbf}

| 20. INSPECT STEERING WHEEL CENTER POINT |

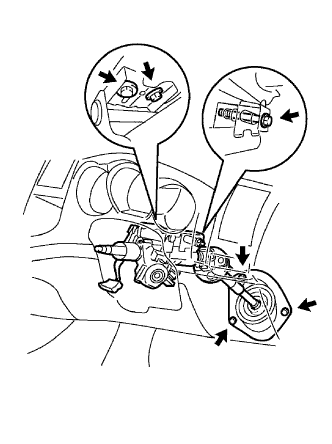

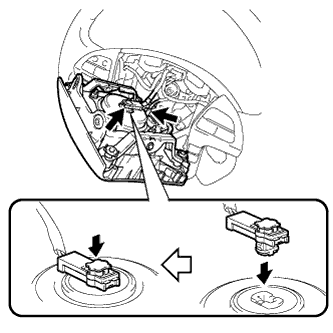

| 21. INSTALL STEERING PAD ASSEMBLY |

Support the steering pad with one hand.

Connect the connector to the steering pad.

- NOTICE:

- When handling the airbag connector, do not damage the airbag wire harness.

Connect the horn connector.

Confirm that the groove along the circumference of the "TORX" screw is attached to the screw case and place the steering pad onto the steering wheel.

Using a T30 "TORX" socket wrench, tighten the 2 screws.

- Torque:

- 8.8 N*m{90 kgf*cm, 78 in.*lbf}

| 22. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 23. INSPECT SRS WARNING LIGHT |

(Toyota Fortuner RM000000XFD0EGX.html)

| 24. ADD POWER STEERING FLUID |

| 25. BLEED AIR FROM POWER STEERING SYSTEM |

(Toyota Fortuner RM00000138601DX.html)

| 26. CHECK POWER STEERING FLUID LEVEL IN RESERVOIR |

| 27. CHECK FOR POWER STEERING FLUID LEAKAGE |

| 28. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT |

(Toyota Fortuner RM0000010MX01RX.html)