Transfer Assembly Reassembly

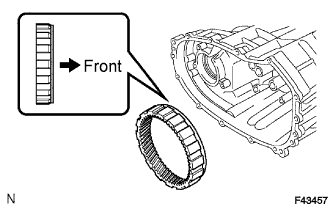

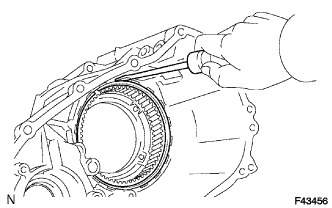

INSTALL TRANSFER LOW PLANETARY RING GEAR

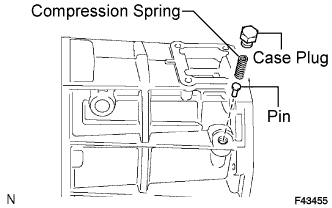

INSTALL TRANSFER CASE STRAIGHT PIN

INSTALL COMPRESSION SPRING

INSTALL TRANSFER CASE PLUG

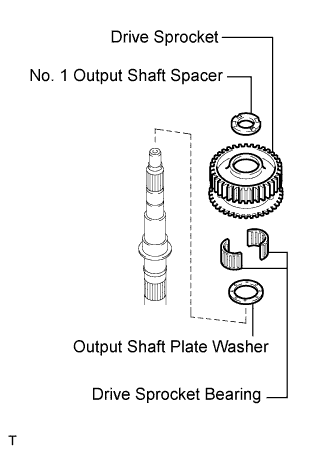

INSTALL TRANSFER OUTPUT SHAFT PLATE WASHER

INSTALL TRANSFER DRIVE SPROCKET BEARING

INSTALL TRANSFER DRIVE SPROCKET SUB-ASSEMBLY

INSTALL NO. 1 TRANSFER OUTPUT SHAFT SPACER

INSTALL REAR TRANSFER OUTPUT SHAFT RADIAL BALL BEARING

INSTALL TRANSFER OUTPUT SHAFT PLATE WASHER

INSTALL FRONT TRANSFER OUTPUT SHAFT NEEDLE ROLLER BEARING

INSTALL TRANSFER CLUTCH HUB

INSTALL CENTER DIFFERENTIAL CASE

INSTALL TRANSFER OUTPUT SHAFT SPACER BALL

INSTALL NO. 2 TRANSFER OUTPUT SHAFT SPACER

INSTALL TRANSFER LOW PLANETARY RING GEAR HOLE SNAP RING

INSPECT TRANSFER DRIVE SPROCKET RADIAL CLEARANCE

INSPECT TRANSFER DRIVE SPROCKET THRUST CLEARANCE

INSTALL TRANSFER LOW PLANETARY GEAR BEARING

INSTALL TRANSFER INPUT SHAFT BEARING

INSTALL TRANSFER LOW PLANETARY GEAR SPLINE PIECE

INSTALL TRANSFER INPUT SHAFT BEARING SNAP RING

INSTALL NO. 1 TRANSFER INPUT SHAFT SEAL RING

INSTALL TRANSFER LOW PLANETARY GEAR BEARING

INSTALL NO. 1 TRANSFER THRUST BEARING RACE

INSTALL TRANSFER INPUT SHAFT

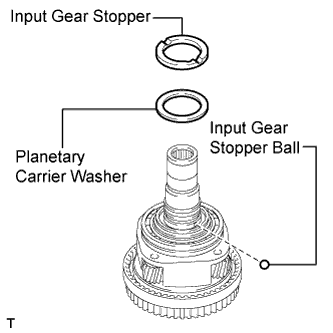

INSTALL MANUAL TRANSFER PLANETARY CARRIER WASHER

INSTALL TRANSFER INPUT GEAR STOPPER BALL

INSTALL TRANSFER INPUT GEAR STOPPER

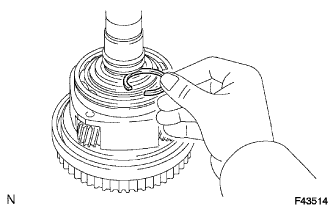

INSTALL TRANSFER INPUT GEAR STOPPER SHAFT SNAP RING

INSTALL TRANSFER CASE OIL SEAL

INSTALL TRANSFER LOW PLANETARY GEAR ASSEMBLY WITH TRANSFER INPUT SHAFT

INSTALL TRANSFER OIL PUMP GEAR

INSTALL TRANSFER OIL PUMP BODY O-RING

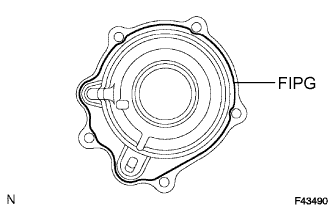

INSTALL TRANSFER OIL PUMP BODY SUB-ASSEMBLY

INSTALL TRANSFER CASE MAGNET

INSTALL TRANSFER OIL SEPARATOR SUB-ASSEMBLY

INSTALL NO. 1 TRANSFER CASE PLUG

INSTALL NO. 1 TRANSFER CASE PLUG

INSTALL TRANSFER INPUT GEAR RADIAL BALL BEARING

INSTALL TRANSFER DRIVEN SPROCKET BEARING

INSTALL REAR TRANSFER OUTPUT SHAFT, FRONT DRIVE CHAIN AND DRIVEN SPROCKET SUB-ASSEMBLY

INSTALL CENTER DIFFERENTIAL LOCK FORK SUB-ASSEMBLY WITH FRONT DRIVE CLUTCH SLEEVE

INSTALL NO. 2 TRANSFER GEAR SHIFT FORK WITH TRANSFER HIGH AND LOW CLUTCH SLEEVE

INSTALL TRANSFER OUTPUT SHAFT FRONT NEEDLE ROLLER BEARING

INSTALL OUTPUT SHAFT SPACER

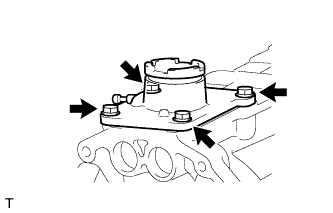

INSTALL REAR TRANSFER CASE

INSTALL TRANSFER OUTPUT SHAFT WASHER

INSTALL TRANSFER EXTENSION HOUSING TYPE T OIL SEAL

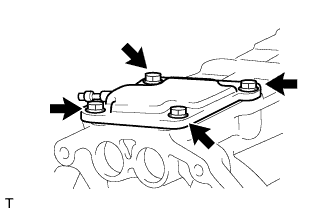

INSTALL TRANSFER EXTENSION HOUSING SUB-ASSEMBLY

INSTALL SPEEDOMETER DRIVEN GEAR SUB-ASSEMBLY WITH VEHICLE SPEED SENSOR

INSTALL TRANSFER OUTPUT SHAFT COMPANION FLANGE OIL SEAL (for Front Side)

INSTALL TRANSFER OUTPUT SHAFT COMPANION FLANGE OIL SEAL (for Rear Side)

INSTALL OUTPUT SHAFT COMPANION FLANGE SUB-ASSEMBLY (for Front Side)

INSTALL OUTPUT SHAFT COMPANION FLANGE SUB-ASSEMBLY (for Rear Side)

INSTALL BREATHER OIL DEFLECTOR

INSTALL TRANSFER CONTROL SHIFT LEVER RETAINER SUB-ASSEMBLY (for Select Lever on Transfer)

INSTALL TRANSFER CASE COVER SUB-ASSEMBLY (for Select Lever on Transfer Adapter)

INSTALL TRANSFER COVER TYPE T OIL SEAL

INSTALL TRANSFER BEARING RETAINER SUB-ASSEMBLY

INSTALL TRANSFER GEAR SHIFT HEAD

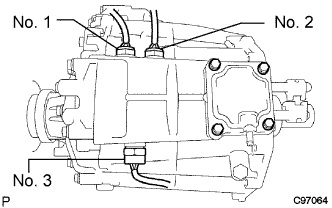

INSTALL TRANSFER INDICATOR SWITCH

Transfer Assembly -- Reassembly |

| 1. INSTALL TRANSFER LOW PLANETARY RING GEAR |

Install the ring gear to the front case.

- NOTICE:

- Make sure to install the ring gear in the correct direction.

Using a screwdriver, install the snap ring.

- NOTICE:

- Make sure that the snap ring is firmly installed to the groove.

| 2. INSTALL TRANSFER CASE STRAIGHT PIN |

| 3. INSTALL COMPRESSION SPRING |

| 4. INSTALL TRANSFER CASE PLUG |

Apply adhesive to the threads of the plug.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the case plug.

- Torque:

- 18.6 N*m{190 kgf*cm, 14 ft.*lbf}

| 5. INSTALL TRANSFER OUTPUT SHAFT PLATE WASHER |

| 6. INSTALL TRANSFER DRIVE SPROCKET BEARING |

| 7. INSTALL TRANSFER DRIVE SPROCKET SUB-ASSEMBLY |

| 8. INSTALL NO. 1 TRANSFER OUTPUT SHAFT SPACER |

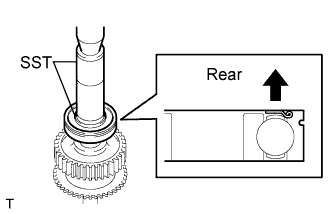

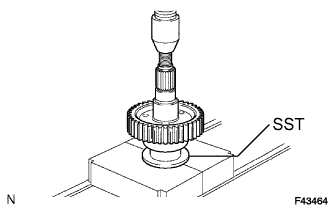

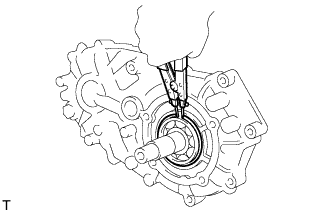

| 9. INSTALL REAR TRANSFER OUTPUT SHAFT RADIAL BALL BEARING |

Apply gear oil to the connecting areas of the output shaft and bearing.

Using SST and a press, press in a new bearing with the outer race snap ring groove toward the rear.

- SST

- 09316-60011(09316-00011,09316-00071)

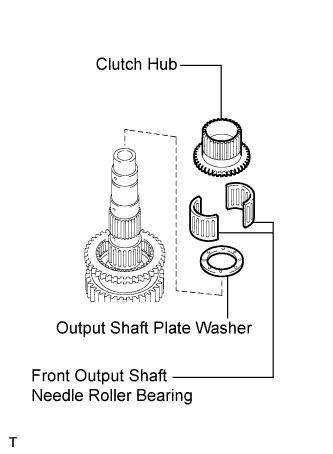

| 10. INSTALL TRANSFER OUTPUT SHAFT PLATE WASHER |

| 11. INSTALL FRONT TRANSFER OUTPUT SHAFT NEEDLE ROLLER BEARING |

| 12. INSTALL TRANSFER CLUTCH HUB |

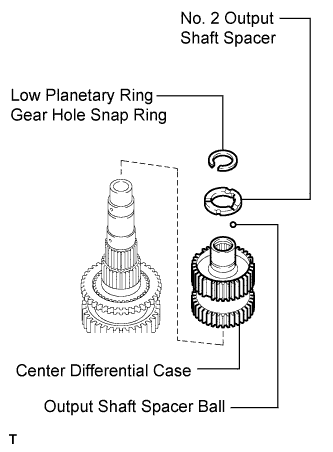

| 13. INSTALL CENTER DIFFERENTIAL CASE |

| 14. INSTALL TRANSFER OUTPUT SHAFT SPACER BALL |

| 15. INSTALL NO. 2 TRANSFER OUTPUT SHAFT SPACER |

| 16. INSTALL TRANSFER LOW PLANETARY RING GEAR HOLE SNAP RING |

Using a snap ring expander, install the snap ring.

- NOTICE:

- Make sure that the snap ring is firmly installed to the groove.

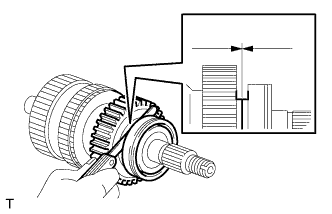

| 17. INSPECT TRANSFER DRIVE SPROCKET RADIAL CLEARANCE |

Using a dial indicator, measure the radial clearance of the drive sprocket.

- Standard clearance:

- 0.01 to 0.06 mm (0.0004 to 0.0024 in.)

- Maximum clearance:

- 0.06 mm (0.0024 in.)

If the clearance is greater than the maximum, replace the drive sprocket, output shaft or needle roller bearing.

| 18. INSPECT TRANSFER DRIVE SPROCKET THRUST CLEARANCE |

Using a feeler gauge, measure the thrust clearance of the drive sprocket.

- Standard clearance:

- 0.15 to 0.24 mm (0.0059 to 0.0094 in.)

- Maximum clearance:

- 0.24 mm (0.0094 in.)

If the clearance is greater than the maximum, replace the drive sprocket.

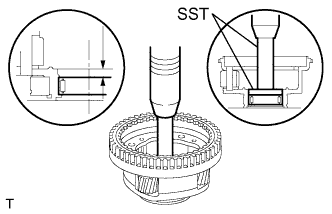

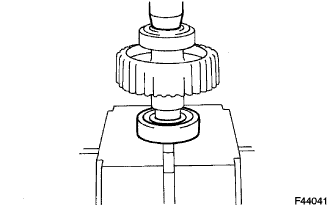

| 19. INSTALL TRANSFER LOW PLANETARY GEAR BEARING |

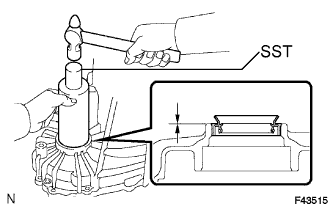

Using SST and a press, press in a new bearing.

- SST

- 09950-60010(09951-00570)

09950-70010(09951-07100)

- Standard depth:

- 7.7 to 8.3 mm (0.303 to 0.327 in.)

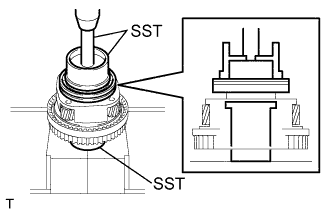

| 20. INSTALL TRANSFER INPUT SHAFT BEARING |

Using SST and a press, press in a new bearing with the groove facing forward.

- SST

- 09223-15020

09515-30010

09950-70010(09951-07100)

| 21. INSTALL TRANSFER LOW PLANETARY GEAR SPLINE PIECE |

Using a screwdriver, install the spline piece and low planetary gear with the snap ring.

- NOTICE:

- Be careful not to damage the spline piece.

- Make sure that the snap ring is firmly installed to the groove.

| 22. INSTALL TRANSFER INPUT SHAFT BEARING SNAP RING |

Select a new snap ring that allows 0.1 mm (0.0039 in.) or less of axial free play.

- Standard snap ring thickness:

Mark

| Thickness

|

1

| 1.45 to 1.50 mm (0.0571 to 0.0591 in.)

|

2

| 1.50 to 1.55 mm (0.0591 to 0.0610 in.)

|

3

| 1.55 to 1.60 mm (0.0610 to 0.0630 in.)

|

4

| 1.60 to 1.65 mm (0.0630 to 0.0650 in.)

|

5

| 1.65 to 1.70 mm (0.0650 to 0.0669 in.)

|

- NOTICE:

- Make sure that the snap ring is firmly installed to the groove.

Using a snap ring expander, install the snap ring.

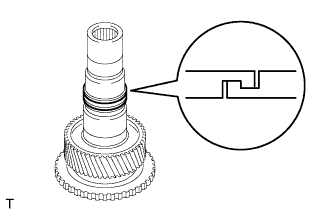

| 23. INSTALL NO. 1 TRANSFER INPUT SHAFT SEAL RING |

Apply gear oil to the 2 seal rings.

Install the 2 seal rings to the input shaft.

- HINT:

- Engage the seal rings securely to eliminate clearance as shown in the illustration.

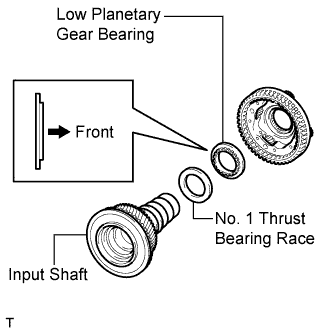

| 24. INSTALL TRANSFER LOW PLANETARY GEAR BEARING |

Install the bearing to the low planetary gear.

- NOTICE:

- Make sure to install the bearing in the correct direction.

| 25. INSTALL NO. 1 TRANSFER THRUST BEARING RACE |

| 26. INSTALL TRANSFER INPUT SHAFT |

Apply gear oil to the contact surface of the input shaft and low planetary gear.

Install the input shaft to the low planetary gear.

| 27. INSTALL MANUAL TRANSFER PLANETARY CARRIER WASHER |

Apply gear oil to the washer.

Install the washer to the low planetary gear.

| 28. INSTALL TRANSFER INPUT GEAR STOPPER BALL |

| 29. INSTALL TRANSFER INPUT GEAR STOPPER |

| 30. INSTALL TRANSFER INPUT GEAR STOPPER SHAFT SNAP RING |

Select a new snap ring that allows 0.05 to 0.15 mm (0.0020 to 0.0059 in.) of axial free play.

- Standard snap ring thickness:

Mark

| Thickness

|

A

| 2.10 to 2.15 mm (0.0827 to 0.0846 in.)

|

B

| 2.15 to 2.20 mm (0.0846 to 0.0866 in.)

|

C

| 2.20 to 2.25 mm (0.0866 to 0.0886 in.)

|

D

| 2.25 to 2.30 mm (0.0886 to 0.0906 in.)

|

E

| 2.30 to 2.35 mm (0.0906 to 0.0925 in.)

|

F

| 2.35 to 2.40 mm (0.0925 to 0.0945 in.)

|

G

| 2.40 to 2.45 mm (0.0945 to 0.0965 in.)

|

H

| 2.45 to 2.50 mm (0.0965 to 0.0984 in.)

|

J

| 2.50 to 2.55 mm (0.0984 to 0.1004 in.)

|

K

| 2.55 to 2.60 mm (0.1004 to 0.1024 in.)

|

L

| 2.60 to 2.65 mm (0.1024 to 0.1043 in.)

|

M

| 2.65 to 2.70 mm (0.1043 to 0.1063 in.)

|

N

| 2.70 to 2.75 mm (0.1063 to 0.1083 in.)

|

P

| 2.75 to 2.80 mm (0.1083 to 0.1102 in.)

|

Q

| 2.80 to 2.85 mm (0.1102 to 0.1122 in.)

|

R

| 2.85 to 2.90 mm (0.1122 to 0.1142 in.)

|

S

| 2.90 to 2.95 mm (0.1142 to 0.1161 in.)

|

T

| 2.95 to 3.00 mm (0.1161 to 0.1181 in.)

|

U

| 3.00 to 3.05 mm (0.1181 to 0.1201 in.)

|

Using a snap ring expander, install the snap ring.

- NOTICE:

- Make sure that the snap ring is firmly installed to the groove.

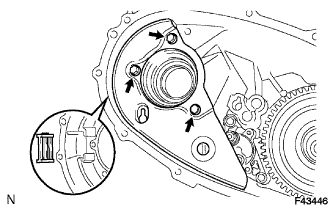

| 31. INSTALL TRANSFER CASE OIL SEAL |

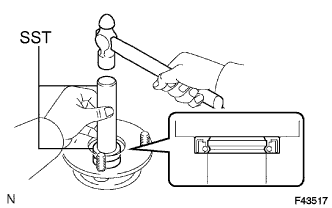

Using SST and a hammer, tap in a new oil seal until its surface is flush with the case upper surface (No. 1).

- SST

- 09316-60011(09316-00011)

- NOTICE:

- Be careful not to damage the front case.

Coat the lip of the oil seal with MP grease.

Using SST and a hammer, tap in a new oil seal until its surface is flush with the case upper surface (No. 2).

- SST

- 09304-12012

- Standard depth:

- -0.5 to 0.5 mm (-0.020 to 0.020 in.)

- NOTICE:

- Be careful not to damage the front case.

Coat the lip of the oil seal with MP grease.

| 32. INSTALL TRANSFER LOW PLANETARY GEAR ASSEMBLY WITH TRANSFER INPUT SHAFT |

Install the low planetary gear with input shaft.

- HINT:

- If necessary, heat the front case to about 50 to 80°C (122 to 176°F).

Using a snap ring expander, install the snap ring.

- NOTICE:

- Make sure that the snap ring is firmly installed to the groove.

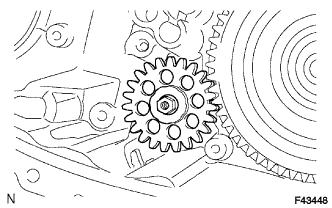

| 33. INSTALL TRANSFER OIL PUMP GEAR |

Apply gear oil to the sliding surface of the gear.

Install the gear with the nut.

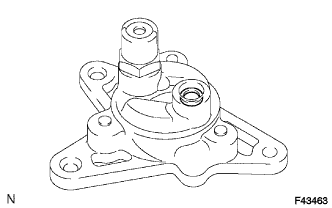

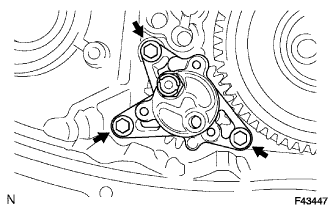

| 34. INSTALL TRANSFER OIL PUMP BODY O-RING |

Coat a new O-ring with gear oil and install it to the oil pump body.

| 35. INSTALL TRANSFER OIL PUMP BODY SUB-ASSEMBLY |

Install the pump body with the 3 bolts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

| 36. INSTALL TRANSFER CASE MAGNET |

| 37. INSTALL TRANSFER OIL SEPARATOR SUB-ASSEMBLY |

Install the oil separator with the 3 bolts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

| 38. INSTALL NO. 1 TRANSFER CASE PLUG |

Install a new gasket and the filler plug (for filler).

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

| 39. INSTALL NO. 1 TRANSFER CASE PLUG |

Install a new gasket and the drain plug.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

| 40. INSTALL TRANSFER INPUT GEAR RADIAL BALL BEARING |

Apply gear oil to the contact surface of the bearing and driven sprocket.

Using SST and a press, press in a new bearing.

- SST

- 09316-60011(09316-00031)

- NOTICE:

- After press-fitting the bearing to the driven sprocket, check that the bearing moves smoothly.

| 41. INSTALL TRANSFER DRIVEN SPROCKET BEARING |

Apply gear oil to the contact surfaces of the bearing and driven sprocket.

Using a press, press in a new bearing.

- NOTICE:

- After press-fitting the bearing to the driven sprocket, check that the bearing moves smoothly.

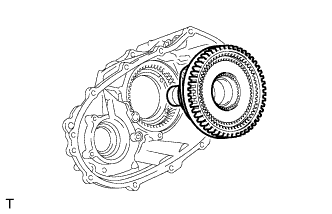

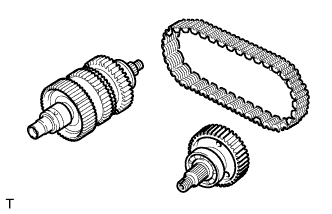

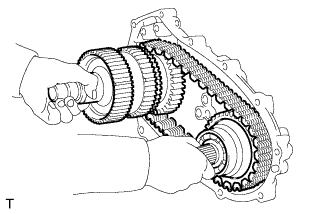

| 42. INSTALL REAR TRANSFER OUTPUT SHAFT, FRONT DRIVE CHAIN AND DRIVEN SPROCKET SUB-ASSEMBLY |

Install the output shaft and driven sprocket to the front drive chain.

Mount the rear case in a vise.

- NOTICE:

- Place aluminum plates on the vise to prevent damage to the rear case.

Install the output shaft, front drive chain and driven sprocket to the rear case.

- HINT:

- Check that the output shaft and driven sprocket turn smoothly. If necessary, heat the rear case to about 50 to 80°C (122 to 176°F).

Using a snap ring expander, install the snap ring.

- NOTICE:

- Make sure that the snap ring is firmly installed to the groove.

| 43. INSTALL CENTER DIFFERENTIAL LOCK FORK SUB-ASSEMBLY WITH FRONT DRIVE CLUTCH SLEEVE |

Install the clutch sleeve.

- NOTICE:

- Make sure to install the clutch sleeve in the correct direction.

Install the front drive shift shaft, center differential lock fork, shift shaft stopper, 2 springs and 3 stoppers.

Install the ball and spring to the hole.

Apply adhesive to the threads of the No. 2 plug.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the No. 2 plug to the hole.

- Torque:

- 18.6 N*m{190 kgf*cm, 14 ft.*lbf}

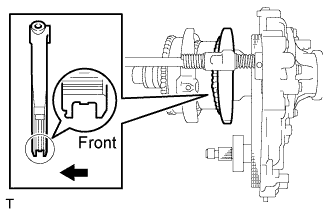

Using a pin punch and hammer, tap in the slotted pin.

- NOTICE:

- When installing the slotted pin, make sure the pin's groove (labeled A) is facing in the same direction as the shaft.

| 44. INSTALL NO. 2 TRANSFER GEAR SHIFT FORK WITH TRANSFER HIGH AND LOW CLUTCH SLEEVE |

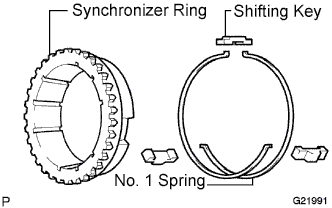

Manual transmission:

Install the synchronizer ring, 3 shifting keys and 2 springs.

- NOTICE:

- Set the No. 1 springs so that their openings do not overlap, as shown in the illustration.

- Make sure that the No. 1 springs are firmly connected to the shifting keys.

Install the straight pin to the hole.

Install the No. 2 gear shift fork, high and low shift fork shaft and high and low clutch sleeve.

- NOTICE:

- Make sure to install the fork in the correct direction.

Install the ball and spring to the hole.

Apply adhesive to the threads of the No. 1 plug.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the No. 1 plug to the hole.

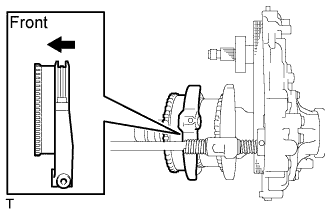

Using a pin punch and hammer, install the slotted pin.

- NOTICE:

- When installing the slotted pin, make sure the pin's groove (labeled A) is facing in the same direction as the shaft.

| 45. INSTALL TRANSFER OUTPUT SHAFT FRONT NEEDLE ROLLER BEARING |

Apply gear oil to the bearing.

Install the bearing to the low planetary gear.

| 46. INSTALL OUTPUT SHAFT SPACER |

| 47. INSTALL REAR TRANSFER CASE |

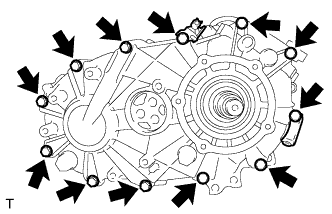

Apply seal packing to the rear case as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- NOTICE:

- If the removed rear case will be reused: After removing the case, be sure to perform the following before reinstalling it: 1) using a knife, cut off any old seal packing on the rear case's contact surface, 2) clean off any remaining old seal packing from the rear case's contact surface, and 3) apply seal packing to the rear case.

Install the 2 clamps and rear case with the 12 bolts.

- Torque:

- 28 N*m{285 kgf*cm, 21 ft.*lbf}

- NOTICE:

- Tighten the bolts of the rear case within 10 minutes of applying the seal packing. The seal packing will dry very quickly.

| 48. INSTALL TRANSFER OUTPUT SHAFT WASHER |

Install the speedometer drive gear and 2 output washers.

| 49. INSTALL TRANSFER EXTENSION HOUSING TYPE T OIL SEAL |

Using SST and a hammer, tap in a new oil seal until its surface is flush with the housing upper surface.

- SST

- 09223-46011

09631-32020

- NOTICE:

- Be careful not to damage the extension housing.

Coat the lip of the oil seal with MP grease.

| 50. INSTALL TRANSFER EXTENSION HOUSING SUB-ASSEMBLY |

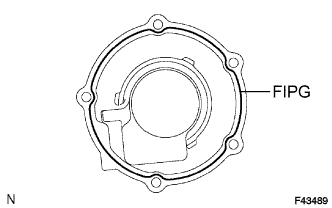

Apply seal packing to the extension housing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- NOTICE:

- If the removed extension housing will be reused: After removing the housing, be sure to perform the following before reinstalling it: 1) using a knife, cut off any old seal packing on the extension housing's contact surface, 2) clean off any remaining old seal packing from the extension housing's contact surface, and 3) apply seal packing to the extension housing.

Apply adhesive to the threads of the bolt.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the extension housing with the 5 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

- NOTICE:

- Tighten the bolts of the extension housing within 10 minutes of applying the seal packing. The seal packing will dry very quickly.

| 51. INSTALL SPEEDOMETER DRIVEN GEAR SUB-ASSEMBLY WITH VEHICLE SPEED SENSOR |

Install the sensor with driven gear with the bolt.

- Torque:

- 11.5 N*m{117 kgf*cm, 8 ft.*lbf}

Connect the sensor connector.

| 52. INSTALL TRANSFER OUTPUT SHAFT COMPANION FLANGE OIL SEAL (for Front Side) |

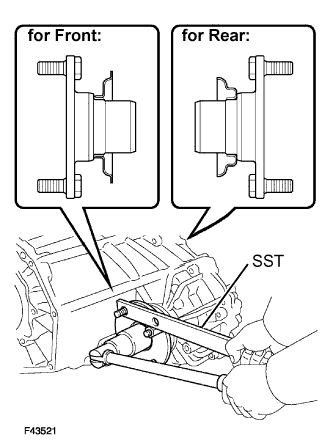

Using SST and a hammer, tap in a new oil seal (for front).

- SST

- 09950-60010(09951-00320)

09950-70010(09951-07100)

- NOTICE:

- Be careful not to damage the companion flange.

Coat the lip of the oil seal with MP grease.

| 53. INSTALL TRANSFER OUTPUT SHAFT COMPANION FLANGE OIL SEAL (for Rear Side) |

Using SST and a hammer, tap in a new oil seal.

- SST

- 09950-60010(09951-00320)

09950-70010(09951-07100)

- NOTICE:

- Be careful not to damage the companion flange.

Coat the lip of the oil seal with MP grease.

| 54. INSTALL OUTPUT SHAFT COMPANION FLANGE SUB-ASSEMBLY (for Front Side) |

Apply gear oil to the connecting areas of the companion flange and driven sprocket.

Install the companion flange to the driven sprocket.

Using SST to hold the companion flange, install a new lock nut.

- SST

- 09330-00021

09950-40011(09951-04020,09952-04010,09953-04030,09955-04051,09957-04010,09958-04011)

- Torque:

- 118 N*m{1,203 kgf*cm, 87 ft.*lbf}

Using a chisel and hammer, stake the lock nut to the driven sprocket.

- NOTICE:

- Thoroughly stake the shaft to the lock nut's groove.

- Be careful not to damage parts around the lock nut.

- Do not apply excessive force to the shaft.

| 55. INSTALL OUTPUT SHAFT COMPANION FLANGE SUB-ASSEMBLY (for Rear Side) |

Apply gear oil to the connecting area of the companion flange and output shaft.

Install the companion flange to the output shaft.

Using SST to hold the companion flange, install a new lock nut.

- SST

- 09330-00021

09950-40011(09951-04020,09952-04010,09953-04030,09954-04010,09955-04051,09957-04010,09958-04011)

- Torque:

- 118 N*m{1,203 kgf*cm, 87 ft.*lbf}

| 56. INSTALL BREATHER OIL DEFLECTOR |

| 57. INSTALL TRANSFER CONTROL SHIFT LEVER RETAINER SUB-ASSEMBLY (for Select Lever on Transfer) |

Install the retainer with the 4 bolts.

- Torque:

- 18 N*m{183 kgf*cm, 13 ft.*lbf}

| 58. INSTALL TRANSFER CASE COVER SUB-ASSEMBLY (for Select Lever on Transfer Adapter) |

Install the case cover with the 4 bolts.

- Torque:

- 18 N*m{183 kgf*cm, 13 ft.*lbf}

| 59. INSTALL TRANSFER COVER TYPE T OIL SEAL |

Using SST and a hammer, tap in a new oil seal until its surface is flush with the retainer upper surface.

- SST

- 09950-60010(09951-00590)

09950-70010(09951-07100)

- NOTICE:

- Be careful not to damage the bearing retainer.

| 60. INSTALL TRANSFER BEARING RETAINER SUB-ASSEMBLY |

Apply seal packing to the bearing retainer as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- NOTICE:

- If the removed bearing retainer will be reused: After removing the retainer, be sure to perform the following before reinstalling it: 1) using a knife, cut off any old seal packing on the bearing retainer's contact surface, 2) clean off any remaining old seal packing from the bearing retainer's contact surface, and 3) apply seal packing to the bearing retainer.

Apply adhesive to the threads of the bolt.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the bearing retainer with the 5 bolts.

- Torque:

- 11.5 N*m{117 kgf*cm, 8 ft.*lbf}

- NOTICE:

- Tighten the bolts of the bearing retainer within 10 minutes of applying the seal packing. The seal packing will dry very quickly.

| 61. INSTALL TRANSFER GEAR SHIFT HEAD |

Install the No. 1 and No. 2 gear shift heads to the front drive shift fork shaft and high and low shift fork shaft.

Using a pin punch and hammer, tap in the 2 slotted pins to the No. 1 and No. 2 gear shift heads.

- NOTICE:

- When installing the slotted pins, make sure the pin's groove (labeled A) is facing in the same direction as the shaft.

| 62. INSTALL TRANSFER INDICATOR SWITCH |

Install new gaskets and the indicator switches.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

- HINT:

- Indicator switch:

No. 1 (for Automatic Transmission)

| Indicator switch (neutral position)

|

No. 2

| Indicator switch (L4 position)

|

No. 3

| Indicator switch (differential lock)

|