Dtc P2716 Pressure Control Solenoid D Electrical (Shift Solenoid Valve Slt)

DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT TRANSMISSION WIRE (SHIFT SOLENOID VALVE SLT)

CHECK WIRE HARNESS (TRANSMISSION WIRE - ECM)

INSPECT SHIFT SOLENOID VALVE SLT

DTC P2716 Pressure Control Solenoid "D" Electrical (Shift Solenoid Valve SLT) |

DESCRIPTION

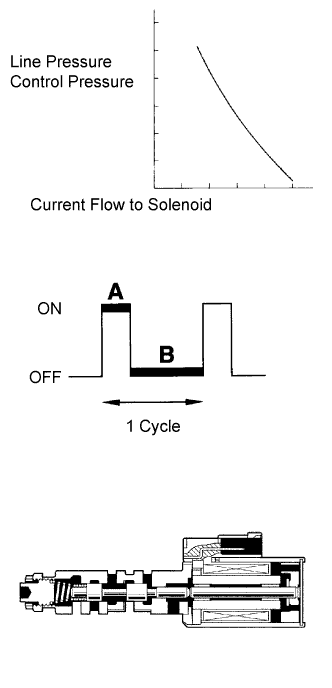

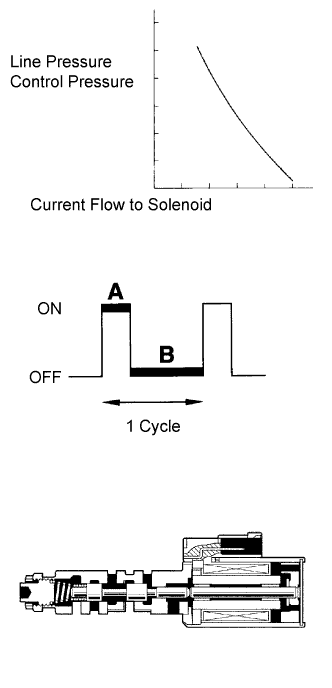

The throttle pressure that is applied to the primary regulator valve (which modulates the line pressure) causes the solenoid valve SLT, under electronic control, to precisely modulate and generate the line pressure according to the extent that the accelerator pedal is depressed or the output of engine power.This controls the line pressure and provides smooth shifting characteristics.Upon receiving a signal of the throttle valve opening angle, the ECM controls the line pressure by sending a predetermined duty ratio* to the solenoid valve, modulating the line pressure and generating throttle pressure.

The throttle pressure that is applied to the primary regulator valve (which modulates the line pressure) causes the solenoid valve SLT, under electronic control, to precisely modulate and generate the line pressure according to the extent that the accelerator pedal is depressed or the output of engine power.This controls the line pressure and provides smooth shifting characteristics.Upon receiving a signal of the throttle valve opening angle, the ECM controls the line pressure by sending a predetermined duty ratio* to the solenoid valve, modulating the line pressure and generating throttle pressure.- HINT:

- *: The duty ratio is the ratio of the current ON time (A) to the total of the current ON and OFF time (A + B).

- Duty Ratio (%) = A / (A + B) x 100

DTC No.

| DTC Detection Condition

| Trouble Area

|

P2716

| Open or short is detected in shift solenoid valve SLT circuit for 1 sec. or more while driving (1 trip detection logic)

| - Open or short in shift solenoid valve SLT circuit

- Shift solenoid valve SLT

- ECM

|

MONITOR DESCRIPTION

When an open or short in the shift solenoid valve SLT circuit is detected, the ECM interprets this as a fault. The ECM will illuminate the MIL and store the DTC.

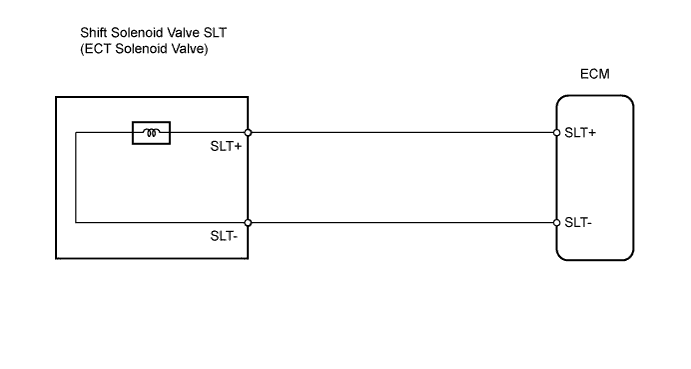

WIRING DIAGRAM

INSPECTION PROCEDURE

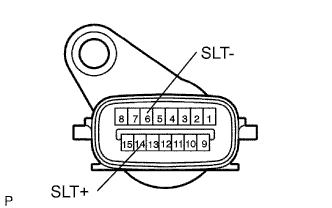

| 1.INSPECT TRANSMISSION WIRE (SHIFT SOLENOID VALVE SLT) |

Disconnect the E1 wire connector.

Measure the resistance of the wire connector.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

14 (SLT+) - 6 (SLT-)

| 20°C (68°F)

| 5.0 to 5.6 Ω

|

14 (SLT+) - Body ground

| 20°C (68°F)

| 1 MΩ or higher

|

6 (SLT-) - Body ground

| 20°C (68°F)

| 1 MΩ or higher

|

| 2.CHECK WIRE HARNESS (TRANSMISSION WIRE - ECM) |

Disconnect the E16 ECM connector.

Measure the resistance of the wire harness side connector.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

E16-13 (SLT+) - E16-12 (SLT-)

| 20°C (68°F)

| 5.0 to 5.6 Ω

|

E16-13 (SLT+) - Body ground

| 20°C (68°F)

| 1 MΩ or higher

|

E16-12 (SLT-) - Body ground

| 20°C (68°F)

| 1 MΩ or higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| 3.INSPECT SHIFT SOLENOID VALVE SLT |

Remove the shift solenoid valve SLT.

Measure the resistance of the solenoid valve.

- Standard resistance:

- 5.0 to 5.6 Ωat 20°C (68°F)

Connect the battery's positive (+) lead with a 21 W bulb to terminal 2 and the negative (-) lead to terminal 1 of the solenoid valve connector. Then check that the valve moves and makes an operating noise.

- OK:

- Valve moves and makes operating noise.

- HINT:

- Reference: Inspect using an oscilloscope.

- Check the waveform of the ECM connector.

- OK:

- Refer to illustration.

Item

| Content

|

Tester Connection

| E16-13 (SLT+) - E16-12 (SLT-)

|

Tool Setting

| 5 V/DIV., 1 msec./DIV.

|

Condition

| Engine idle speed

|

| | REPLACE SHIFT SOLENOID VALVE SLT |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE TRANSMISSION WIRE |

|