Oil Pump -- Installation |

| 1. INSTALL TIMING CHAIN COVER OIL SEAL |

Using a screwdriver, pry out the oil seal.

- NOTICE:

- Be careful not to damage the oil pump body.

- HINT:

- Tape the screwdriver tip before use.

Using SST and a hammer, tap in a new oil seal until its surface is flush with the timing chain cover edge.

- SST

- 09226-10010

|

Apply MP grease to the lip of the oil seal.

| 2. INSTALL TIMING CHAIN COVER |

Remove any old seal packing (FIPG material) and be careful not to drop any oil on the contact surfaces of the timing chain cover, cylinder head and cylinder block.

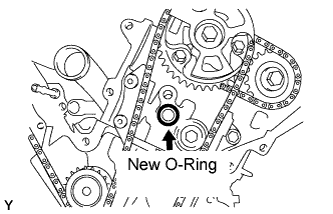

Install a new O-ring to the cylinder head LH as shown in the illustration.

|

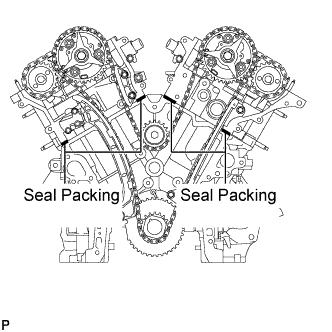

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.5 to 4.5 mm (0.14 to 0.18 in.)

|

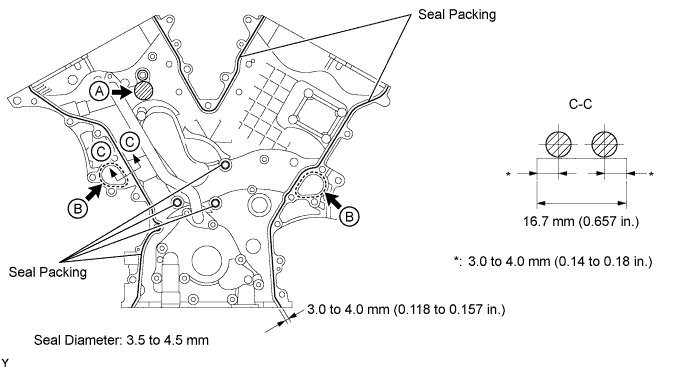

Apply seal packing in a continuous line to the timing chain cover as shown in the illustration.

- Seal packing:

- for water related parts labeled "B":

- Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent

- for oil related parts:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.5 to 4.5 mm (0.14 to 0.18 in.)

- NOTICE:

- Install the timing chain cover within 3 minutes after applying seal packing. After installing the timing chain cover, the timing chain cover bolts and nuts must be tightened within 15 minutes. Otherwise the seal packing must be removed and reapplied.

- Do not apply seal packing to the position labeled "A" shown in the illustration.

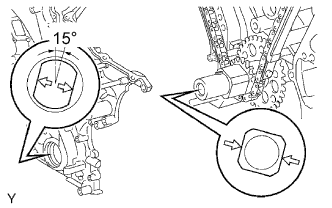

Align the hole of the oil pump drive rotor with the rectangular portion of the crankshaft timing sprocket, and slide the timing chain cover into place.

|

Install the timing chain cover with the 15 bolts and 2 nuts. Uniformly tighten the bolts and nuts in several passes.

- Torque:

- 23 N*m{235 kgf*cm, 17 ft.*lbf}

- NOTICE:

- Do not allow any seal packing to contact the chain and slipper when installing the timing chain cover.

- HINT:

- Each bolt length is as follows:

- A: 25 mm (0.98 in.)

- B: 55 mm (2.17 in.)

|

| 3. INSTALL OIL FILTER BRACKET |

Install a new gasket and the oil filter bracket with the 3 bolts and 2 nuts.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

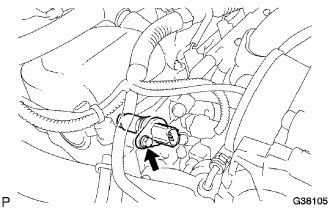

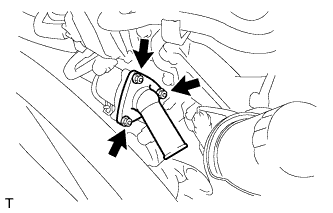

| 4. INSTALL VVT SENSOR |

Install the sensor with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

|

Connect the sensor connector.

| 5. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE |

Apply a light coat of engine oil to a new O-ring of the oil control valve.

|

Install the oil control valve with the bolt.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

- NOTICE:

- Be careful that the O-ring is not cracked when installing the oil control valve.

|

Connect the camshaft timing oil control valve connector.

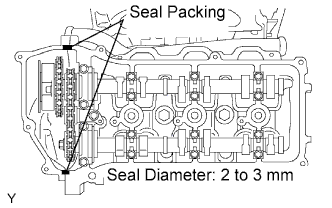

| 6. INSTALL CYLINDER HEAD COVER LH |

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the cylinder head, timing chain cover and cylinder head cover.

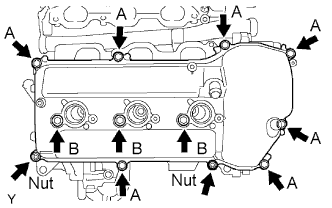

Apply seal packing (diameter: 2 to 3 mm (0.08 to 0.12 in.)) to the cylinder head and timing chain cover as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 2 to 3 mm (0.08 to 0.12 in.)

- NOTICE:

- Install the cylinder head cover within 3 minutes after applying seal packing. After installing it, the cylinder head cover bolts and nuts must be tightened within 15 minutes. Otherwise the seal packing must be removed and reapplied.

|

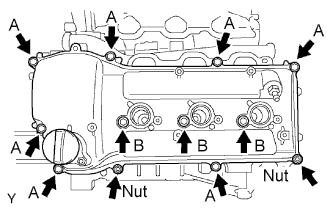

Install the seal washers to the bolts.

Install the cylinder head cover with the 10 bolts and 2 nuts. Uniformly tighten the bolts and nuts in several passes.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}for bolt A

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}for bolt B

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}for nut

|

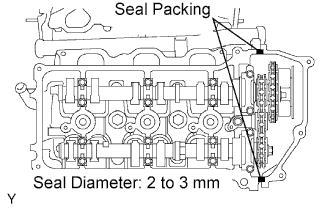

| 7. INSTALL CYLINDER HEAD COVER RH |

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the cylinder head, timing chain cover and cylinder head cover.

Apply seal packing to the cylinder head and timing chain cover as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 2 to 3 mm (0.08 to 0.12 in.)

- NOTICE:

- Install the cylinder head cover within 3 minutes after applying seal packing. After installing it, the cylinder head cover bolts and nuts must be tightened within 15 minutes. Otherwise the seal packing must be removed and reapplied.

|

Install the seal washers to the bolts.

Install the cylinder head cover with the 10 bolts and 2 nuts. Uniformly tighten the bolts and nuts in several passes.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}for bolt A

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}for bolt B

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}for nut

|

| 8. INSTALL IGNITION COIL |

Install the 6 ignition coils with the 6 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 9. INSTALL NO. 1 OIL PAN |

Remove any old seal packing (FIPG material) and be careful not to drop any oil on the contact surfaces of the cylinder block, rear oil seal retainer and oil pan.

Install a new O-ring to the oil pump.

|

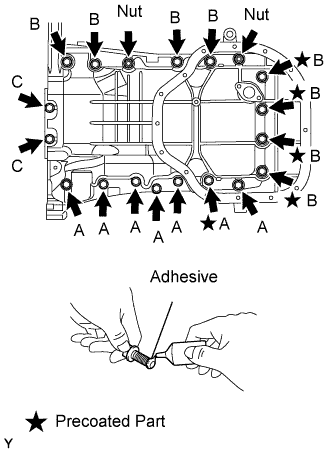

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3 to 4 mm (0.12 to 0.16 in.)

- NOTICE:

- Remove any oil from the contact surface.

- Install the oil pan within 3 minutes after applying seal packing. After installing it, the oil pan bolts and nuts must be tightened within 15 minutes.

- Do not start the engine for at least 4 hours after the installation.

|

Install the oil pan with the 17 bolts and 2nuts. Uniformly tighten the bolts and nuts in several passes.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf} for bolt A

- 21 N*m{214 kgf*cm, 15 ft.*lbf} for bolt B

- 10 N*m{102 kgf*cm, 7 ft.*lbf}for bolt C

- 21 N*m{214 kgf*cm, 15 ft.*lbf} for nuts

- HINT:

- Each bolt length is as follows:

- A = 25 mm (0.98 in.)

- B = 45 mm (1.77 in.)

- C = 14 mm (0.55 in.)

- NOTICE:

- The bolts indicated by stars in the illustration are precoated parts. When reusing them, apply adhesive to 2 or 3 threads before installation.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

|

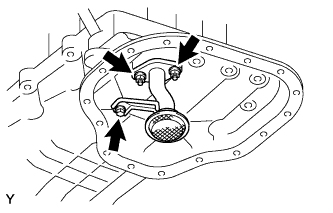

| 10. INSTALL OIL STRAINER |

Install a new gasket and the oil strainer with bolt and 2 nuts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

| 11. INSTALL NO. 2 OIL PAN |

Remove any old seal packing (FIPG material) and be careful not to drop any oil on the contact surfaces of the oil pan and No. 2 oil pan.

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3 to 4 mm (0.12 to 0.16 in.)

- NOTICE:

- Remove the oil from the contact surface.

- Install the oil pan within 3 minutes after applying seal packing. After installing it, the oil pan bolts and nuts must be tightened within 15 minutes. Otherwise the seal packing must be removed and reapplied.

- Do not start the engine for at least 4 hours after the installation.

|

Install the No. 2 oil pan with the 14 bolts and 2 nuts. Uniformly tighten the bolts and nuts in several passes.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf} for bolts

- 10 N*m{102 kgf*cm, 7 ft.*lbf} for nuts

|

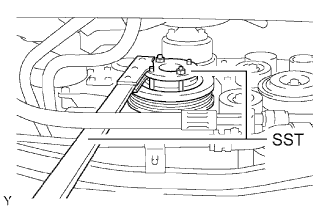

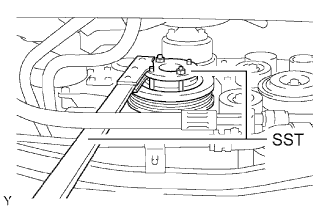

| 12. INSTALL CRANKSHAFT PULLEY |

Using SST, install the pulley set bolt.

- SST

- 09213-54015(91651-60855)

09330-00021

- Torque:

- 250 N*m{2,549 kgf*cm, 184 ft.*lbf}

|

| 13. INSTALL NO. 1 IDLER PULLEY |

Install the idler pulley with the bolt.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

- HINT:

- "DOUBLE" is marked on the No. 1 idler pulley to distinguish it from the No. 2 idler pulley.

|

| 14. INSTALL NO. 2 IDLER PULLEY |

- NOTICE:

- w/o Integrated Type:

- The installation of the No. 2 idler pulleys differs depending on the mark on the No. 2 idler pulleys shown in the illustration.

- HINT:

- Use the same procedure for both No. 2 idler pulleys.

w/ Idler Pulley Cover Plate (PU107013ARMXY3):

Install the idler pulley cover plate, idler pulley and No. 2 idler pulley cover plate with the bolt.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

- NOTICE:

- If it is necessary to replace the pulley or either plate, replace the No. 2 idler pulley cover plate, No. 2 idler pulley and idler pulley cover plate as a set with new parts.

- When replacing parts, make sure to replace the No. 2 idler pulley with a new pulley marked "PU107013ARMXY3".

w/o Idler Pulley Cover Plate (PU107013ARMXY1):

Install the idler pulley and No. 2 idler pulley cover plate with the bolt.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

- NOTICE:

- If it is necessary to replace the pulley or plate, replace both the pulley and plate with a set of new parts that includes a No. 2 idler pulley cover plate, No. 2 idler pulley and idler pulley cover plate.

- When replacing parts, make sure to replace the No. 2 idler pulley with a new pulley marked "PU107013ARMXY3".

for Integrated Type:

Install the 2 No. 2 idler pulleys with the 2 bolts.- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

|

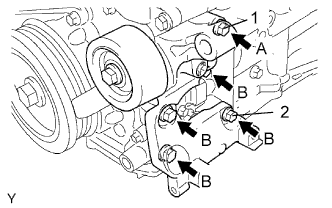

| 15. INSTALL V-RIBBED BELT TENSIONER |

Temporarily install the V-ribbed belt tensioner with the 5 bolts.

|

Install the V-ribbed belt tensioner by tightening bolt 1 and then bolt 2.

- Torque:

- 36 N*m{367 kgf*cm, 27 ft.*lbf}

Tighten the other bolts.

- Torque:

- 36 N*m{367 kgf*cm, 27 ft.*lbf}

- HINT:

- Each bolt length is as follows:

- A = 70 mm (2.76 in.)

- B = 33 mm (1.30 in.)

| 16. INSTALL GENERATOR |

|

Install the generator and adjusting bar with the 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

Install the generator wire with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Install the terminal cap.

Connect the generator connector.

| 17. INSTALL WATER INLET |

Install a new gasket to the water inlet housing with thermostat.

|

Install the water inlet housing with thermostat with the 3 nuts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

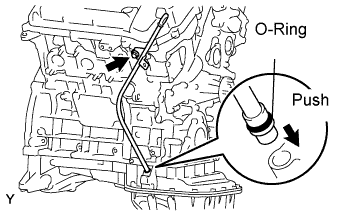

| 18. INSTALL OIL DIPSTICK GUIDE |

Install a new O-ring to the oil dipstick guide.

|

Apply a light coat of engine oil to the O-ring.

Push in the oil dipstick guide end into the guide hole of the oil pan.

Install the oil dipstick guide with the bolt.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

Install the oil dipstick gauge.

| 19. REMOVE ENGINE ASSEMBLY FROM STAND |

| 20. INSTALL FLYWHEEL (for Manual Transmission) |

Using SST, hold the crankshaft.

- SST

- 09213-54015(91651-60855)

09330-00021

|

Apply adhesive to 2 or 3 threads of the mounting bolt end.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

|

Install the flywheel.

|

Install and tighten the 8 mounting bolts uniformly in several steps.

- Torque:

- 83 N*m{846 kgf*cm, 61 ft.*lbf}

| 21. INSTALL DRIVE PLATE AND RING GEAR ASSEMBLY (for Automatic Transmission) |

Using SST, hold the crankshaft.

- SST

- 09213-54015(91651-60855)

09330-00021

|

Apply adhesive to 2 or 3 threads of the mounting bolt end.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

|

Install the front spacer, drive plate and rear spacer to the crankshaft.

|

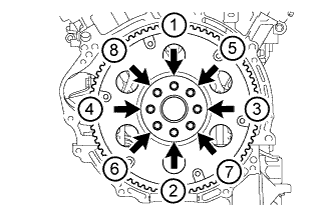

Install and uniformly tighten the 8 bolts in several steps in the order shown in the illustration.

- Torque:

- 83 N*m{846 kgf*cm, 61 ft.*lbf}

| 22. INSTALL ENGINE ASSEMBLY |

Install the engine assembly to the vehicle (Toyota Fortuner RM000000YMF003X.html).

| 23. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

| 24. ADD ENGINE OIL |

Clean and install the oil drain plug with a new gasket.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

Add fresh engine oil.

- Standard capacity:

Item Specified Condition Drain and refill with oil filter change 5.5 liters (5.8 US qts, 4.8 Imp. qts) Drain and refill without oil filter change 5.2 liters (5.5 US qts, 4.6 Imp. qts) Dry fill 6.6 liters (7.0 US qts, 5.8 Imp. qts)

Install the oil filler cap.

| 25. ADD ENGINE COOLANT |

Tighten all the plugs and fill the radiator with TOYOTA Super Long Life Coolant (SLLC).

- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf} for cylinder block drain cock plug

- Standard capacity:

Item Specified Condition A/T 9.8 liters (10.4 US qts, 8.6 Imp. qts) M/T 8.5 liters (9.0 US qts, 7.5 Imp. qts)

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

- Please contact your TOYOTA dealer for further details.

- NOTICE:

- Never use water as a substitute for engine coolant.

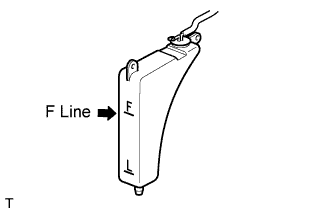

Fill the radiator reservoir with TOYOTA Super Long Life Coolant (SLLC) to the F line.

Install the radiator cap.

Bleed air from the cooling system.

Warm up the engine until the thermostat opens.

While the thermostat is open, circulate the coolant for several minutes.Maintain the engine speed at 2,500 to 3,000 rpm.

Press the inlet and outlet radiator hoses several times by hand to bleed air.

- CAUTION:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine and wait until the coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Check the coolant level in the radiator reservoir.

If the coolant level is below the L line, add SLLC to the reservoir F line.

|

| 26. CHECK FOR ENGINE COOLANT LEAKS |

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

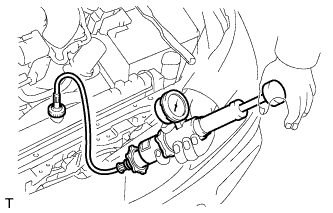

Fill the radiator with coolant and attach a radiator cap tester.

|

Warm up the engine.

Using the radiator cap tester, increase the pressure inside the radiator to 118 kPa (1.2 kgf/cm2, 17.1 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks. If no external leaks are found, check the cylinder block and head.

| 27. CHECK FOR FUEL LEAKS |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON.

- NOTICE:

- Do not start the engine.

Push the intelligent tester main switch ON.

To perform the Active Test, enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

|

Check the fuel pump operation.

Check for pressure in the fuel inlet tube from the fuel line. Check that the sound of fuel flowing in the fuel tank can be heard.

If there is no sound, check the integration relay, fuel pump, ECM and wiring connector.

Check for fuel leaks.

Check that there are no fuel leaks after performing maintenance anywhere on the system.

If there are fuel leaks, repair or replace the leaking parts.

| 28. CHECK FOR ENGINE OIL LEAKS |

| 29. INSTALL V-BANK COVER |

Install the V-bank cover with the 2 nuts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

| 30. INSPECT IGNITION TIMING |

When using intelligent tester:

Check the ignition timing.Connect the intelligent tester to the DLC3.

- HINT:

- Refer to the intelligent tester operator's manual for further details.

- Standard ignition timing:

- 7 to 24°BTDC @ idle

(Transmission in neutral position)

Disconnect the intelligent tester from the DLC3.

|

When not using intelligent tester:

Check the ignition timing.Remove the air cleaner cap.

Connect the tester probe of a timing light to the green-red lead wire of the ignition coil connector of the No. 1 cylinder.

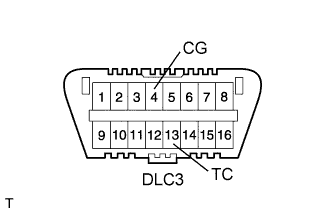

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

Using the timing light, check the ignition timing.

- Standard ignition timing:

- 10 +-2° BTDC @ idle

(Transmission in neutral position)

Remove SST from the DLC3.

Check the ignition timing.

- Standard ignition timing:

- 7 to 24° BTDC @ idle

(Transmission in neutral position)

Disconnect the timing light from the engine.

Install the air cleaner cap.

|

| 31. INSPECT IDLE SPEED |

When using intelligent tester:

Check the idle speed.Connect the intelligent tester to the DLC3.

- HINT:

- Refer to the intelligent tester operator's manual for further details.

Switch the air conditioning OFF.

Race the engine at 2,500 rpm for approximately 90 seconds.

Check the idle speed.

- Standard idle speed:

- 700 +-50 rpm

(Transmission in neutral position)

Disconnect the intelligent tester from the DLC3.

|

When not using intelligent tester:

Check the idle speed.Using SST, connect the tachometer probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

Switch the air conditioning OFF.

Race the engine speed at 2,500 rpm for approximately 90 seconds.

Check the idle speed.

- Standard idle speed:

- 700 +-50 rpm

(Transmission in neutral position)

Disconnect the tachometer from the DLC3.

|

| 32. INSPECT CO/HC |

- HINT:

- This check is for determining whether or not the idle CO/HC complies with regulations.

Start the engine.

Keep the engine speed at 2,500 rpm for approximately 180 seconds.

Insert a CO/HC meter testing probe at least 40 cm (1.3 ft.) into the tailpipe during idling.

|

Immediately check CO/HC concentration at idle and/or 2,500 rpm.

- HINT:

- When performing the 2 mode (2,500 rpm and idle) test, check that the CO/HC concentration complies with local regulations.

- If the CO/HC concentration does not comply with regulations, troubleshoot in the order given below.

Check the A/F sensor operation and heated oxygen sensor operation.

See the table below for possible causes, then inspect and correct the applicable causes if necessary.

CO HC Symptom Causes Normal High Rough idle 1. Faulty ignitions: - Incorrect timing

- Plugs are contaminated, shorted, or gaps are defective

3. Leaky intake and exhaust valves

4. Leaky cylinderLow High Rough idle

(Fluctuating HC reading)1. Vacuum leaks: - PCV hose

- Intake manifold

- Throttle body

High High Rough idle

(Black smoke from exhaust)1. Restricted air filter

2. Faulty SFI system:- Faulty pressure regulator

- Defective ECT sensor

- Faulty ECM

- Faulty injector

- Faulty throttle position sensor

- Faulty MAF sensor

- Incorrect timing