Cylinder Head -- Installation |

- HINT:

- Thoroughly clean all parts to be assembled.

- Before installing the parts, apply fresh engine oil to all sliding and rotating surfaces.

- Replace all gaskets and oil seals with new one.

| 1. INSTALL CYLINDER HEAD GASKET |

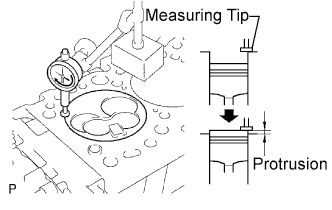

Check piston protrusion for each cylinder.

Clean the cylinder block with solvent.

Set the piston of the cylinder to be measured to slightly before TDC.

Place a dial indicator on the cylinder block, and set the measuring tip as shown in the illustration.

Set the dial indicator at 0 mm (0 in.).

- HINT:

- Use a dial indicator measuring tip as shown in the illustration.

- Make sure that the measuring tip is flat against the cylinder block gasket surface and piston head when taking the measurements.

Find where the piston head protrudes most by slowly turning the crankshaft clockwise and counterclockwise.

Measure the protrusion of each cylinder at 2 places as shown in the illustration, making a total of 8 measurements.

For the piston protrusion value of each cylinder, use the average of the 2 measurements of each cylinder.

- Standard piston protrusion:

- 0.68 to 0.97 mm (0.0268 to 0.0382 in.)

|

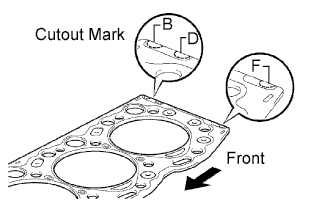

Select a new cylinder head gasket.

- HINT:

- There are 3 sizes of new cylinder head gaskets, marked "B", "D" or "F" accordingly.

- Cylinder head gasket thickness:

Cutout Mark Thickness B 1.40 to 1.50 mm (0.0551 to 0.0591 in.) D 1.50 to 1.60 mm (0.0591 to 0.0630 in.) F 1.60 to 1.70 mm (0.0630 to 0.0669 in.)

Select the largest piston protrusion value from the measurements made, then select a new appropriate gasket according to the table below.

- Use gasket size:

Gasket Size Piston Protrusion Use B 0.68 to 0.77 mm (0.0268 to 0.0303 in.) Use D 0.78 to 0.87 mm (0.0307 to 0.0343 in.) Use F 0.88 to 0.97 mm (0.0346 to 0.0382 in.)

|

Place a new cylinder head gasket in position on the cylinder block.

- NOTICE:

- Be careful of the installation direction.

|

| 2. INSTALL CYLINDER HEAD SUB-ASSEMBLY |

- HINT:

- Set the No. 1 cylinder to 90° BTDC/compression to avoid interference with the piston top and valve head.

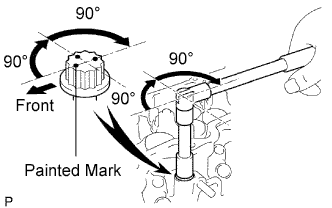

- The cylinder head bolts are tightened in 3 progressive steps.

- If any bolt is broken or deformed, replace it.

Using the crankshaft pulley bolt, turn the crankshaft 90° counterclockwise, and align the timing mark of the crankshaft timing pulley with the protrusion of the timing belt case.

|

Place the cylinder head in position on the cylinder head gasket.

Apply a light coat of engine oil on the threads and under the heads of the cylinder head bolts.

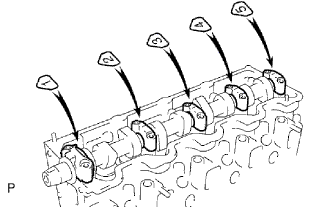

Install and uniformly tighten the 18 cylinder head bolts, in several passes in the sequence shown in the illustration.

- Torque:

- 78 N*m{800 kgf*cm, 58 ft.*lbf}

- Bolt length A:

- 107 mm (4.21 in.)

- Bolt length B:

- 127 mm (5.00 in.)

|

Mark the front of the cylinder head bolt with paint.

|

Retighten the cylinder head bolts 90° in the numerical order shown above.

Retighten the cylinder head bolts by an additional 90°.

Check that the painted marks are now facing rearward.

| 3. INSTALL CAMSHAFT |

Set the No. 1 cylinder to 90° BTDC/compression.

- HINT:

- Set the No. 1 cylinder to 90° BTDC/compression to avoid interference with the piston top and valve head.

Using the crankshaft pulley bolt, turn the crankshaft, and align the timing mark of the crankshaft timing pulley with the protrusion of the timing belt case.

Install the camshaft.

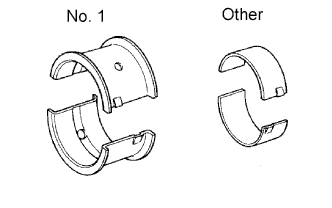

- NOTICE:

- Different bearings are used for the No. 1 and other.

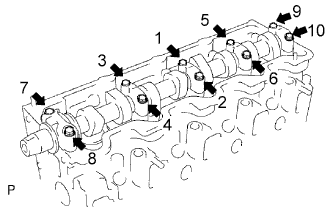

Install the 10 bearings to the bearing caps and cylinder head.

Place the camshaft on the cylinder head with the key groove facing upward.

Install the 5 bearing caps in their proper locations.

Apply a light coat of engine oil to the threads and under the heads of the bearing cap bolts.

Install and uniformly tighten the 10 bearing cap bolts, in several steps, in the sequence shown in the illustration.

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

|

| 4. INSTALL CAMSHAFT OIL SEAL RETAINER |

Install a new gasket and the retainer with the 4 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

| 5. INSTALL NO. 2 TIMING BELT COVER |

Install the timing belt cover with the 4 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

| 6. INSTALL CAMSHAFT TIMING PULLEY |

Install the woodruff key to the key groove of the camshaft.

Align the pulley set key with the timing mark facing outward.

Using SST, install the pulley with the bolt.

- SST

- 09960-10010(09962-01000,09963-01000)

- Torque:

- 98 N*m{1,000 kgf*cm, 72 ft.*lbf}

|

| 7. INSPECT VALVE CLEARANCE |

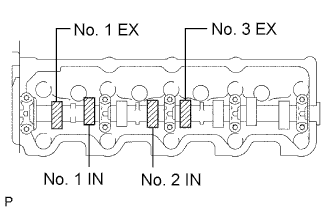

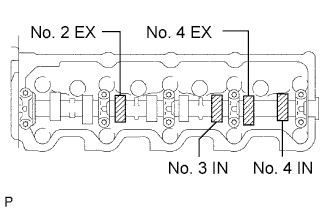

Check only the valves indicated in the illustration.

Using a feeler gauge, measure the clearance between the valve lifter and camshaft.

Record the out-of-specification valve clearance measurements. They will be used later to determine the required replacement adjusting shim.

- Standard valve clearance (Cold):

Intake Exhaust 0.20 to 0.30 mm (0.008 to 0.012 in.) 0.40 to 0.50 mm (0.016 to 0.020 in.)

|

Turn the crankshaft one revolution (360°) and align the mark as shown in the illustration.

|

Check only the valves indicated in the illustration. Measure the valve clearance. (see procedure in the first step)

- Standard valve clearance (Cold):

Intake Exhaust 0.20 to 0.30 mm (0.008 to 0.012 in.) 0.40 to 0.50 mm (0.016 to 0.020 in.)

|

| 8. ADJUST VALVE CLEARANCE |

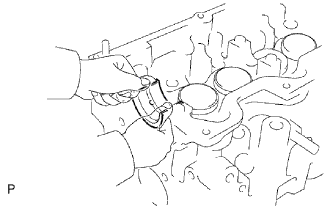

Remove the adjusting shim.

Turn the crankshaft so that the cam lobe of the camshaft on the adjusting valve points upward.

Using SST, press down the valve lifter.

- SST

- 09248-64011

Position the notch of the valve lifter with it facing the exhaust manifold side.

Remove the adjusting shim with a screwdriver and magnetic finger.

|

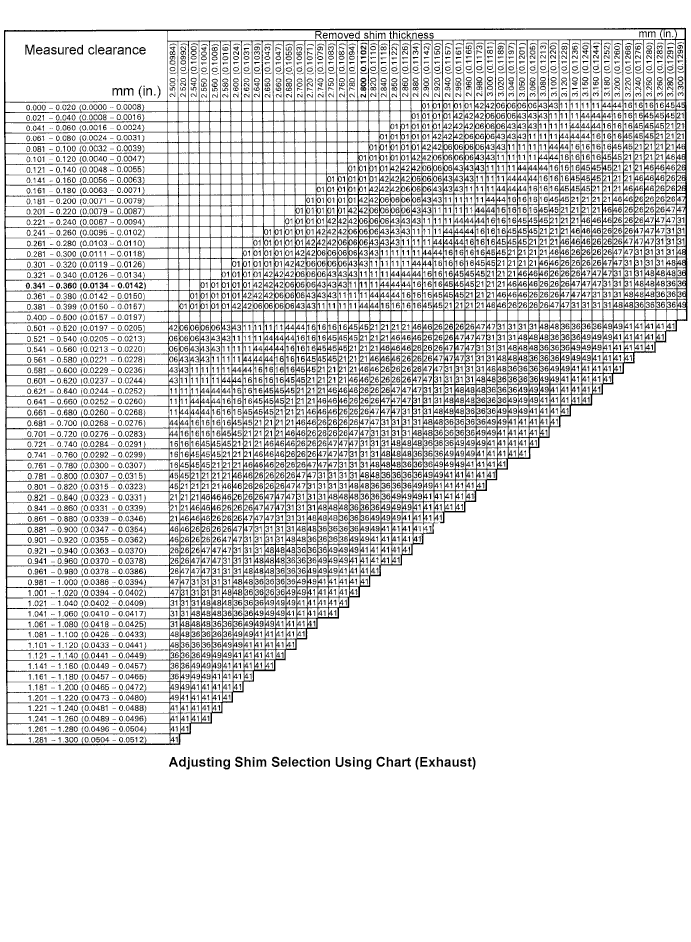

Determine the replacement adjusting shim size by following the formula or charts:

Using a micrometer, measure the thickness of the removed shim.

Calculate the thickness of a new shim so that the valve clearance comes within the specified value.

T = Thickness of removed shim

A = Measured valve clearance

N = Thickness of new shimIntake N = T + (A - 0.25 mm (0.010 in.)) Exhaust N = T + (A - 0.45 mm (0.018 in.)) Select a new shim with a thickness as close as possible to the calculated value.

- HINT:

- Shims are available in 17 sizes in increments of 0.05 mm (0.0020 in.), from 2.50 mm (0.0984 in.) to 3.30 mm (0.1299 in.).

New shim thickness Shim No. Thickness Shim No. Thickness 01 2.50 mm (0.0984 in.) 46 2.95 mm (0.1161 in.) 42 2.55 mm (0.1004 in.) 26 3.00 mm (0.1181 in.) 06 2.60 mm (0.1024 in.) 47 3.05 mm (0.1201 in.) 43 2.65 mm (0.1043 in.) 31 3.10 mm (0.1220 in.) 11 2.70 mm (0.1063 in.) 48 3.15 mm (0.1240 in.) 44 2.75 mm (0.1083 in.) 36 3.20 mm (0.1260 in.) 16 2.80 mm (0.1102 in.) 49 3.25 mm (0.1280 in.) 45 2.85 mm (0.1122 in.) 41 3.30 mm (0.1299 in.) 21 2.90 mm (0.1142 in.) - - - Standard intake valve clearance (Cold):

- 0.20 to 0.30 mm (0.008 to 0.012 in.)

The 2.800 mm (0.1102 in.) shim is installed and the measured clearance is 0.350 mm (0.0138 in.). Replace the 2.800 mm (0.1102 in.) shim with a No. 21 shim.

New shim thickness Shim No. Thickness Shim No. Thickness 01 2.50 mm (0.0984 in.) 46 2.95 mm (0.1161 in.) 42 2.55 mm (0.1004 in.) 26 3.00 mm (0.1181 in.) 06 2.60 mm (0.1024 in.) 47 3.05 mm (0.1201 in.) 43 2.65 mm (0.1043 in.) 31 3.10 mm (0.1220 in.) 11 2.70 mm (0.1063 in.) 48 3.15 mm (0.1240 in.) 44 2.75 mm (0.1083 in.) 36 3.20 mm (0.1260 in.) 16 2.80 mm (0.1102 in.) 49 3.25 mm (0.1280 in.) 45 2.85 mm (0.1122 in.) 41 3.30 mm (0.1299 in.) 21 2.90 mm (0.1142 in.) - - - Standard exhaust valve clearance (Cold):

- 0.40 to 0.50 mm (0.016 to 0.020 in.)

The 2.800 mm (0.1102 in.) shim is installed and the measured clearance is 0.350 mm (0.0138 in.). Replace the 2.800 mm (0.1102 in.) shim with a No. 11 shim.

|

Install a new adjusting shim.

Place a new adjusting shim on the valve lifter.

Remove the SST.

|

Recheck the valve clearance.

| 9. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

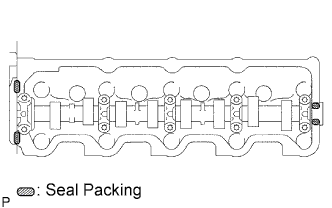

Remove any old seal packing material.

Apply seal packing to the cylinder head as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

|

Install the gasket to the cylinder head cover.

Install the cylinder head cover with the 9 bolts and nut. Uniformly tighten the bolts and nuts in several steps.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

Connect the ventilation hose.

| 10. INSTALL INTAKE MANIFOLD |

Install a new gasket to the cylinder head with the protrusion facing upward.

|

Install the intake manifold with the 6 bolts and 2 nuts. Uniformly tighten the bolts and nuts in several steps.

- Torque:

- 23.5 N*m{240 kgf*cm, 17 ft.*lbf}

|

| 11. INSTALL EXHAUST MANIFOLD |

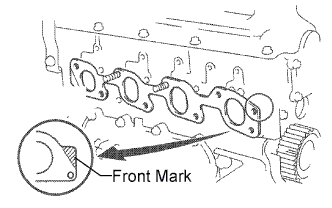

Install a new gasket to the cylinder head.

- HINT:

- Be sure to install a new gasket in the correct direction as shown in the illustration.

|

Install the exhaust manifold with the 6 bolts and 2 new nuts. Uniformly tighten the bolts and nuts in several steps.

- Torque:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

|

| 12. INSTALL WATER OUTLET HOUSING |

Install a new gasket to the cylinder head.

Install the outlet hosing with the 3 bolts.

- Torque:

- 19 N*m{195 kgf*cm, 14 ft.*lbf}

|

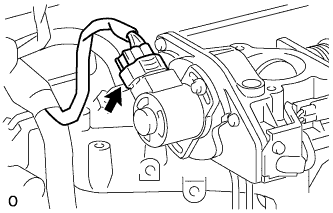

| 13. INSTALL GLOW PLUG ASSEMBLY |

Using a 12 mm deep socket wrench, install the 4 glow plugs.

- Torque:

- 13 N*m{130 kgf*cm, 10 ft.*lbf}

|

| 14. INSTALL NO. 1 GLOW PLUG CONNECTOR |

Install the glow plug connector by uniformly tightening the 4 nuts.

- Torque:

- 1.0 N*m{10 kgf*cm, 9 in.*lbf}

Install the 4 screw grommets.

Connect the glow plug connector wire with the nut.

- Torque:

- 8.4 N*m{85 kgf*cm, 74 in.*lbf}

| 15. INSTALL INJECTION PIPE SET |

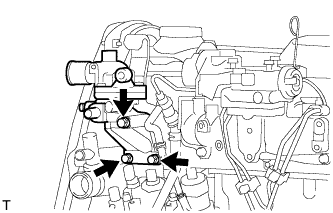

Connect the 2 lower pipe clamps onto the intake manifold.

|

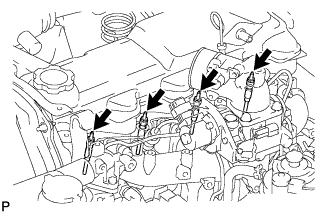

Install the 4 injection pipes.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (Toyota Fortuner RM000000UYX010X.html).

Secure the injection pipes with the 2 upper pipe clamps and 2 nuts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

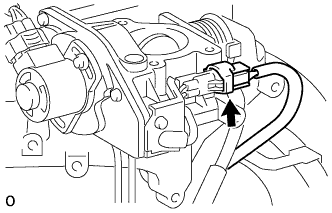

| 16. INSTALL VENTURI ASSEMBLY |

Place a new gasket and the venturi on the intake manifold.

Connect the throttle control motor connector.

|

Connect the throttle open switch connector.

|

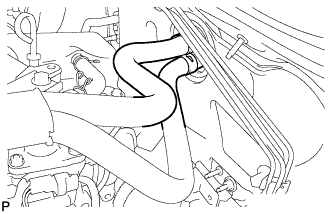

| 17. CONNECT HEATER HOSE |

Connect the 2 heater hose.

|

| 18. INSTALL TIMING BELT |

Install the timing belt (Toyota Fortuner RM00000126H002X.html).

| 19. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Install a new gasket to the front exhaust pipe.

- NOTICE:

- Do not reuse the gasket.

Temporarily install the pipe support and clamp to the front exhaust pipe with the bolt.

Install the front exhaust pipe to the exhaust manifold with 3 new nuts. Alternately tighten the nuts in several passes.

- Torque:

- 62 N*m{632 kgf*cm, 46 ft.*lbf}

- NOTICE:

- Do not reuse the 3 nuts.

Install the pipe support to the transmission with the 2 bolts.

- Torque:

- 71 N*m{724 kgf*cm, 52 ft.*lbf}

Tighten the pipe support's clamp with the bolt.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

Install the front fender seal LH with the 5 clips.

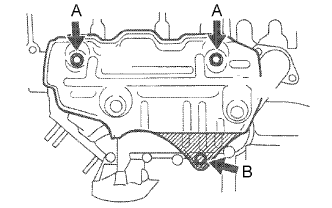

| 20. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with the 3 bolts.

- Torque:

- 18 N*m{185 kgf*cm, 13 ft.*lbf}for bolt A

- 19 N*m{195 kgf*cm, 14 ft.*lbf}for bolt B

|

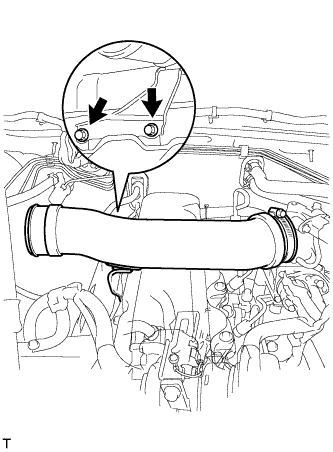

| 21. INSTALL INTAKE PIPE |

|

Install the intake pipe with the 2 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

Tighten the intake pipe clamp.

| 22. INSTALL AIR CLEANER ASSEMBLY |

Install the cleaner with the 2 bolts.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

Connect the connector to the IAT sensor.

Connect the hose clamp.

| 23. ADD ENGINE COOLANT |

Tighten the radiator drain cock plug by hand.

Tighten the cylinder block drain cock plug.

- Torque:

- 57 N*m{581 kgf*cm, 42 ft.*lbf}

Fill the radiator with TOYOTA Super Long Life Coolant (SLLC) to the reservoir tank's FULL line.

- Standard capacity:

- 9.4 liters (9.9 US qts, 8.3 Imp. qts)

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

- Please contact your TOYOTA dealer for further details.

- NOTICE:

- Never use water as a substitute for engine coolant.

|

Press the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level drops below the LOW line, add TOYOTA SLLC to the FULL line.

Install the radiator reservoir cap.

Using a wrench, install the vent plug.

- Torque:

- 2.0 N*m{20 kgf*cm, 18 in.*lbf}

|

Bleed air from the cooling system.

Warm up the engine until the thermostat opens. While the thermostat is open, circulate the coolant for several minutes.

Maintain the engine speed at 2,500 to 3,000 rpm.

Press the inlet and outlet radiator hoses several times by hand to bleed air.

- CAUTION:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine and wait until the coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator reservoir cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

After the coolant cools down, check that the coolant level is at the FULL line.

If the coolant level is below the LOW line, add TOYOTA SLLC to the FULL line.

|

| 24. ADD ENGINE OIL |

Add fresh engine oil.

- Standard capacity:

Item Specified Condition Drain and refill with oil filter change 7.2 liters (7.6 US qts, 6.3 Imp. qts) Drain and refill without oil filter change 6.7 liters (7.1 US qts, 5.9 Imp. qts) Dry fill 8.4 liters (8.9 US qts, 7.4 Imp. qts)

Install the oil filler cap.

| 25. TIGHTEN FUEL TANK CAP ASSEMBLY |

| 26. BLEED AIR FROM FUEL SYSTEM |

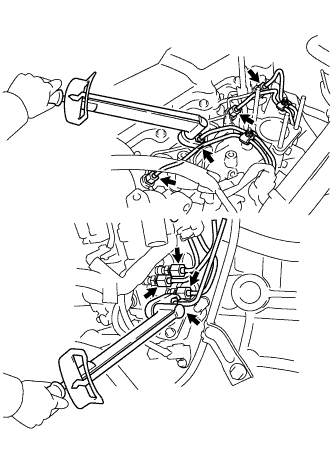

Move the priming pump in the upper part of the fuel filter assembly up and down, and fill the injection pump assembly and fuel system with fuel.

Loosen one of the union nuts (on the nozzle side).

Crank the engine until fuel comes out from the union nut (on the nozzle side).

Tighten the union nut.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (Toyota Fortuner RM000000UYX010X.html).

Perform the procedures above for each injection pipe.

| 27. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 28. INSPECT FOR COOLANT LEAK |

Check for engine coolant leaks (Toyota Fortuner RM000001443007X_01_0001.html).

| 29. INSPECT FOR FUEL LEAK |

Check that there are no fuel leaks anywhere on the fuel system after performing maintenance.

- HINT:

- When checking for fuel leaks, make sure that there is pressure in the fuel line.

| 30. INSPECT FOR OIL LEAK |

Start the engine, and check that there are no oil leaks after performing maintenance.

| 31. INSPECT FOR EXHAUST GAS LEAK |

| 32. INSPECT IDLE ENGINE SPEED |

Warm up the engine.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

Measure the idle speed.

- Standard idle speed:

- 720 to 820 rpm (A/C OFF)

750 to 850 rpm (A/C ON)

- HINT:

- Refer to the intelligent tester operator's manual for further details.

When not using the intelligent tester:

Using SST, connect the tachometer test probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18040

Measure the idle speed.

- Standard idle speed:

- 720 to 820 rpm (A/C OFF)

750 to 850 rpm (A/C ON)

- NOTICE:

- Switch off all accessories.

| 33. INSPECT MAXIMUM ENGINE SPEED |

Start the engine.

Fully depress the accelerator pedal.

Measure the maximum speed.

- Maximum speed:

- 4,850 to 4,950 rpm

| 34. INSTALL NO. 2 ENGINE UNDER COVER |

Install the under cover with the 4 bolts.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 35. INSTALL NO. 1 ENGINE UNDER COVER |

Install the under cover with the 8 bolts.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}