Engine Unit -- Reassembly |

- NOTICE:

- When replacing the injectors (including shuffling the injectors between the cylinders), common rail or cylinder head, it is necessary to replace the injection pipes with new ones.

- When replacing the fuel supply pump, common rail, cylinder block, cylinder head, cylinder head gasket or timing gear case, it is necessary to replace the fuel inlet pipe with a new one.

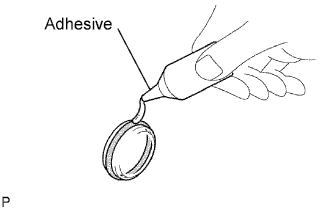

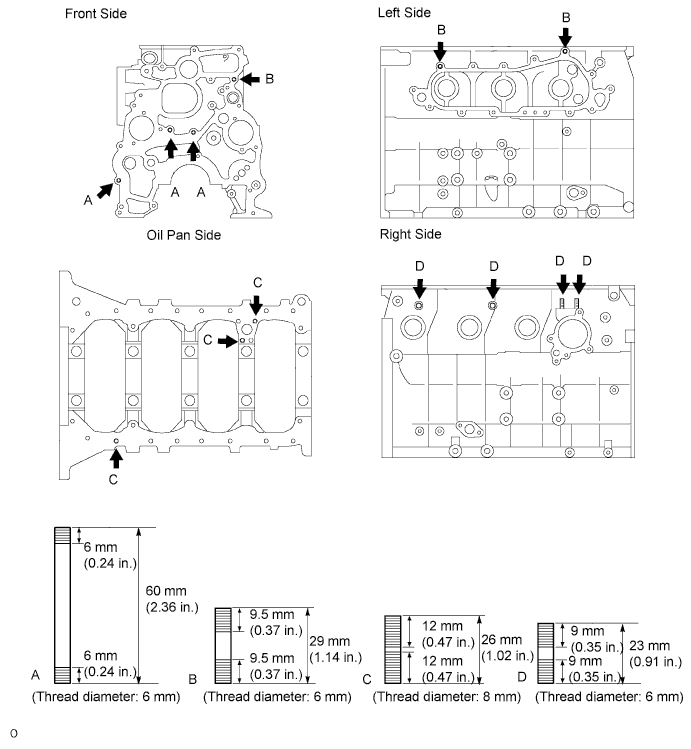

| 1. INSTALL TIGHT PLUG |

|

Apply adhesive to the end of new tight plugs.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

- NOTICE:

- Do not start the engine for 1 hour after the installation.

Position A:

Using a 14 mm steel bar and hammer, tap in the tight plug to the position shown in the illustration.

Other positions:

Using SST and a hammer, tap in new tight plugs to the positions shown in the illustration.

Position B- SST

- 09950-60010(09951-00180)

09950-70010(09951-07100)

- SST

- 09950-60010(09951-00190)

09950-70010(09951-07100)

- SST

- 09950-60010(09951-00200)

09950-70010(09951-07100)

- SST

- 09950-60010(09951-00350)

09950-70010(09951-07100)

- SST

- 09950-60010(09951-00400,09951-00450)

09950-70010(09951-07100)

- SST

- 09950-60010(09951-00450)

09950-70010(09951-07100)

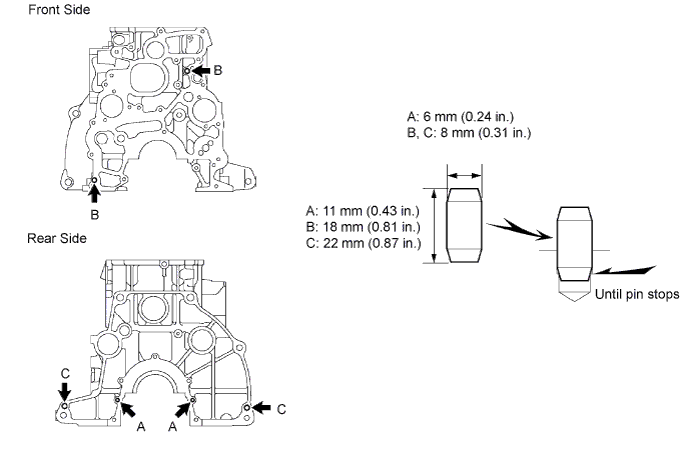

| 2. INSTALL STUD BOLT |

| 3. INSTALL STRAIGHT PIN |

| 4. INSTALL RING PIN |

| 5. INSTALL NO. 1 WITH HEAD STRAIGHT SCREW PLUG |

Install a new gasket and the screw plug.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

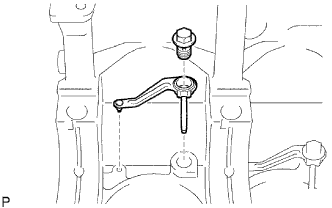

| 6. INSTALL NO. 1 OIL NOZZLE SUB-ASSEMBLY |

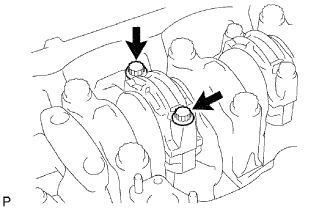

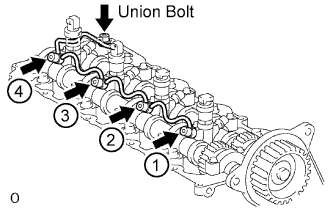

|

Align the pin of the oil nozzle with the pin hole of the cylinder block.

Install the 4 oil nozzles and 4 check valves.

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

| 7. INSTALL PISTON WITH PIN |

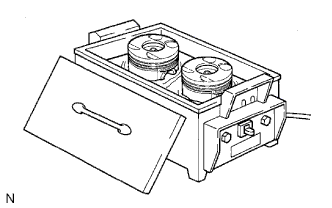

|

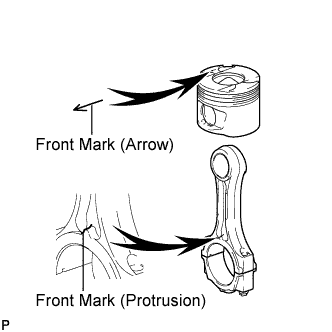

Assemble the piston and connecting rod.

Using a small screwdriver, install a new snap ring on one side of the piston pin hole.

Gradually heat the piston to about 80°C (176°F).

Coat the piston pin with engine oil.

Align the front marks of the piston and connecting rod, and push in the piston pin with your thumb.

Check the fit between the piston and piston pin. Try to move the piston back and forth on the piston pin.

Using a small screwdriver, install a new snap ring on the other side of the piston pin hole.

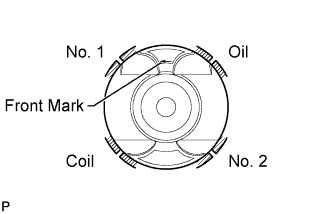

Install the piston rings.

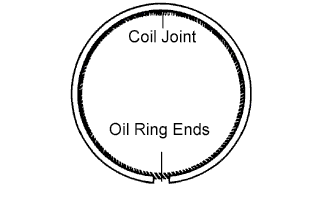

Install the coil and oil ring by hand.

- HINT:

- Face the end gap of the oil ring in the opposite direction of the coil joint.

Using a piston ring expander, install the No. 1 and No. 2 piston rings with the code mark facing upward.

- Code mark:

Number Mark No. 1 NKD No. 2 N

Position the piston rings so that the ring ends are as shown.

- NOTICE:

- Do not align the ring ends.

|

| 8. INSTALL CONNECTING ROD BEARING |

|

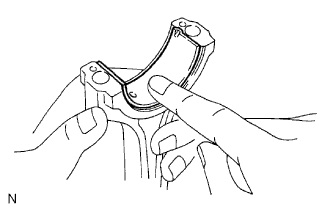

Align the bearing claw with the groove of the connecting rod or connecting cap.

Install the bearings in the connecting rod and connecting rod cap.

| 9. INSTALL CRANKSHAFT BEARING |

|

- HINT:

- Upper bearings have an oil groove and oil hole. Lower bearings do not.

Align the bearing claw with the claw groove of the cylinder block, and push in the 5 upper bearings.

Align the bearing claw with the claw groove of the crankshaft bearing cap, and push in the 5 lower bearings.

| 10. INSTALL CRANKSHAFT SUB-ASSEMBLY |

|

Place the crankshaft on the cylinder block.

Install the 2 upper thrust washers to the No. 5 journal position of the cylinder block.

Push the crankshaft toward the front (rear) side.

Install the 2 thrust washers with the oil grooves facing outward.

Install the 2 thrust washers on the No. 5 bearing cap with the grooves facing outward.

|

Install the 5 crankshaft bearing caps in their proper locations.

|

Install the crankshaft bearing cap bolts.

- HINT:

- The crankshaft bearing cap bolts are tightened in 2 progressive steps.

- If a crankshaft bearing cap bolt is broken or deformed, replace it.

Apply a light coat of engine oil on the threads and under the bolt heads of the main bearing caps.

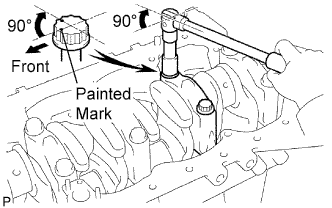

Install and uniformly tighten the 10 bolts of the main bearing caps in several passes in the sequence shown in the illustration.

- Torque:

- 50 N*m{510 kgf*cm, 37 ft.*lbf}

Mark the front of the crankshaft bearing cap bolts with paint.

Retighten the crankshaft bearing cap bolts 90° in the numerical order shown in the previous illustration.

Check that the painted mark is now at a 90° angle to the front.

|

Check that the crankshaft turns smoothly.

Check the crankshaft thrust clearance.

| 11. INSTALL PISTON AND CONNECTING ROD |

|

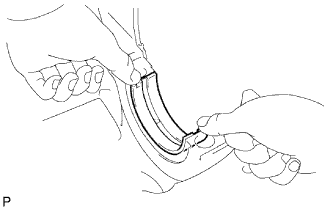

Using a piston ring compressor, push the correctly numbered piston and connecting rod assembly into the cylinder with the front mark of the piston facing forward.

Place the connecting rod cap on the connecting rod.

Match the numbered connecting rod cap with the connecting rod.

Align the pins of the connecting rod cap with the pin holes of the connecting rod, and install the connecting rod cap.

Check that the front mark of the connecting rod cap is facing forward.

|

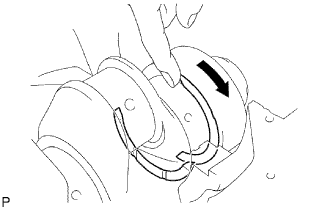

Install the connecting rod cap bolts.

- HINT:

- The connecting rod cap bolts are tightened in 2 progressive steps.

- If any connecting rod bolt is broken or deformed, replace it.

Apply a light coat of engine oil on the threads and under the heads of the connecting rod cap bolts.

Install and alternately tighten the bolts of the connecting rod cap in several passes.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

Mark the front of the connecting rod cap bolts with paint.

Retighten the connecting rod cap bolts 90° as shown.

Check that the painted mark is now at a 90° angle to the front.

|

Check that the crankshaft turns smoothly.

Check the connecting rod thrust clearance (Toyota Fortuner RM00000147Q004X_01_0051.html).

| 12. INSTALL CYLINDER BLOCK OIL ORIFICE |

| 13. INSTALL REAR ENGINE OIL SEAL RETAINER |

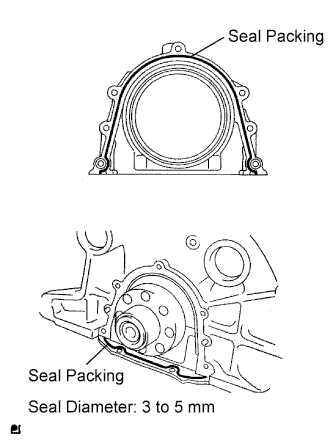

|

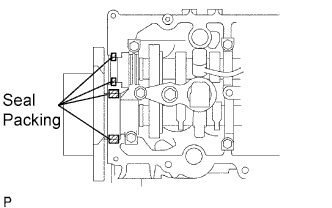

Remove oil seal packing (FIPG) from the oil pan and cylinder block.

Apply seal packing to the specific places described in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3 to 5 mm (0.12 to 0.20 in.)

- NOTICE:

- After applying FIPG, install the engine rear oil seal retainer within 3 minutes and tighten its bolts within 15 minutes.

Install the retainer with the 5 bolts. Alternately tighten the 5 bolts in several passes.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

|

| 14. INSTALL NO. 2 BALANCE SHAFT DRIVEN GEAR |

|

Mount the balance shaft between aluminum plates in a vise.

- NOTICE:

- Be careful not to damage the balance shaft.

Align the balance shaft knock pin with the knock pin hole. Then install the balance shaft thrust washer and balance shaft driven gear.

Install the bolt.

- Torque:

- 36 N*m{367 kgf*cm, 27 ft.*lbf}

| 15. INSTALL NO. 2 BALANCE SHAFT SUB-ASSEMBLY |

|

Install the balance shaft with the 2 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

| 16. INSTALL NO. 1 BALANCE SHAFT DRIVEN GEAR |

|

Mount the balance shaft between aluminum plates in a vise.

- NOTICE:

- Be careful not to damage the balance shafts.

Align the balance shaft knock pin with the knock pin hole. Then install the balance shaft thrust washer and balance shaft driven gear.

Install the bolt.

- Torque:

- 36 N*m{367 kgf*cm, 27 ft.*lbf}

| 17. INSTALL NO. 1 BALANCE SHAFT SUB-ASSEMBLY |

|

Install the balance shaft with the 2 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

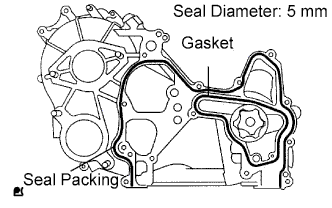

| 18. INSTALL TIMING GEAR CASE ASSEMBLY |

Remove any old packing (FIPG) material.

Apply seal packing to the timing gear case as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 5 mm (0.20 in.)

- NOTICE:

- Install the timing gear case within 3 minutes and tighten its bolts within 15 minutes as soon as application of FIPG is completed.

|

Install a new gasket to the groove of the timing gear case.

|

Install 2 new O-rings to the cylinder block groove of the timing gear case.

|

Align the "2" marks of the balance shaft driven gear No. 1 and oil pump drive gear.

|

Align the mark on the oil pump drive gear with the mark on the timing gear case.

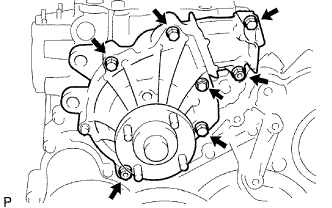

Install the timing gear case with the union bolt and 8 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}for bolt

- 16 N*m{163 kgf*cm, 12 ft.*lbf}for union bolt (A)

|

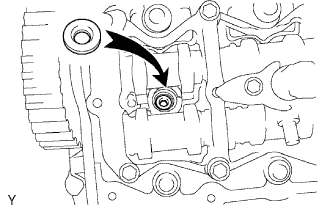

Remove the screw plug.

|

Pour in approximately 20 cc (0.12 cu in.) of engine oil into the oil pump.

Reinstall a new gasket and the screw plug.

- Torque:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

| 19. INSTALL OIL STRAINER SUB-ASSEMBLY |

Install a new gasket and the oil strainer with the 2 bolts and 2 nuts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 20. INSTALL OIL PAN SUB-ASSEMBLY |

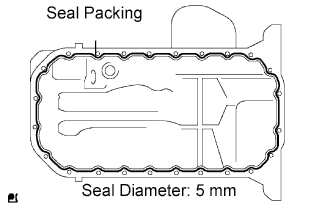

|

Remove any old packing (FIPG) material.

Apply seal packing to the oil pan as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 5 mm (0.20 in.)

- NOTICE:

- Install the oil pan within 3 minutes and tighten its bolts within 15 minutes as soon as application of FIPG is completed.

Install the oil pan with the 22 bolts and 2 nuts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

Install the oil level gauge sensor with the 4 bolts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 21. INSTALL CRANKSHAFT TIMING GEAR OR SPROCKET |

|

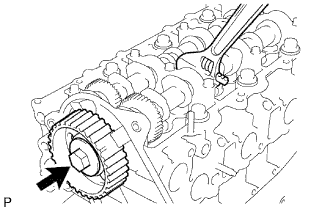

Face the crankshaft timing gear with the "1" timing marks facing forward.

Align the set key on the crankshaft with the key groove of the crankshaft timing gear.

Using SST and a hammer, tap in the timing gear.

- SST

- 09223-00010

| 22. INSTALL SUPPLY PUMP GEAR |

Install the supply pump with the 2 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Align the "3" marks of the balance shaft driven gear No. 2 and supply pump gear.

|

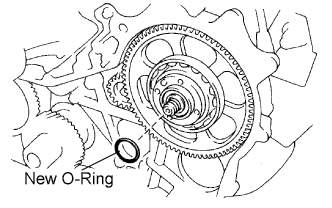

Install a new O-ring to the supply pump gear.

|

Install the supply pump gear set nut.

|

Using SST, tighten the nut.

- SST

- 09960-10010(09962-01000,09963-01000)

- Torque:

- 64 N*m{653 kgf*cm, 47 ft.*lbf}

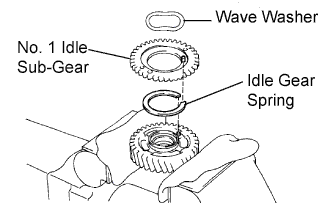

| 23. INSTALL NO. 2 IDLE SUB-GEAR |

|

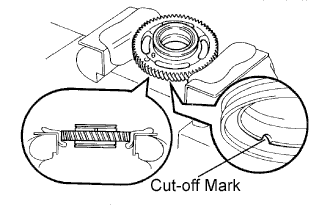

Mount the No.1 idle gear in a vise.

- HINT:

- The cut-off mark of the idle gear faces down.

- NOTICE:

- Be careful not to damage the gear.

Install the idle gear spring.

|

Install the No. 2 idle sub-gear.

Install the wave washer.

- HINT:

- Fit the pins on the gears to the spring ends.

Using snap ring pliers, install the snap ring.

|

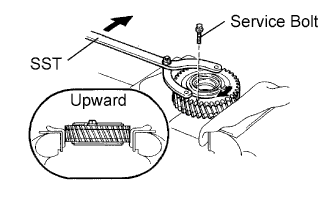

Using SST, align the holes of the No. 1 idle gear and No. 2 idle sub-gear by turning the No. 2 idle sub-gear clockwise, and install a service bolt.

- SST

- 09960-10010(09962-01000,09963-00700)

|

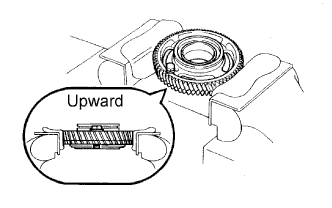

Remove the No. 1 idle gear from the vise and turn it upside down.

| 24. INSTALL NO. 1 IDLE SUB-GEAR |

|

Mount the No. 1 idle gear and No. 2 idle sub-gear in a vise.

- NOTICE:

- Be careful not to damage the gears.

Remove the service bolt.

|

Install the idle gear spring.

|

Install the No. 1 idle sub-gear.

Install the wave washer.

- HINT:

- Fit the pins on the gears to the spring ends.

Using snap ring pliers, install the snap ring.

|

Using SST, align the holes of the No. 1 idler gear and No. 1 idle sub-gear by turning the No. 1 idle sub-gear clockwise, and install a service bolt.

- SST

- 09960-10010(09962-01000,09963-00600)

|

| 25. INSTALL NO. 1 IDLE GEAR |

|

Install the gear shaft as shown in the illustration.

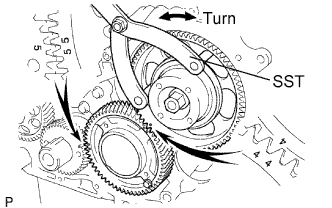

Align the "5" timing marks of the idle gear and crankshaft timing gear.

|

Using SST, turn the supply pump gear, and align the "4" timing marks of the idle gear and supply pump gear, and mesh the gears.

- SST

- 09960-10010(09962-01000,09963-01000)

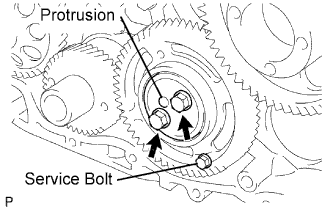

Face the thrust plate with the protrusion facing forward.

|

Align the bolt holes, and install the thrust plate with the 2 bolts.

- Torque:

- 50 N*m{510 kgf*cm, 37 ft.*lbf}

Remove the service bolt.

| 26. INSTALL NO. 1 CRANKSHAFT POSITION SENSOR PLATE |

|

Align the set key with the key groove of the sensor plate.

Install the sensor plate, facing the cup side outward.

| 27. INSTALL TIMING GEAR COVER |

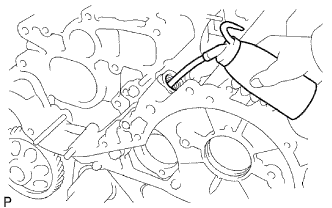

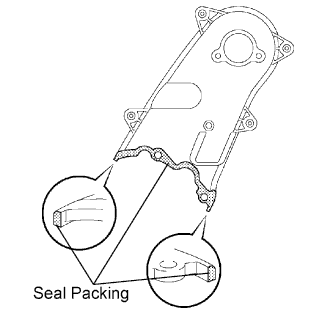

Remove any old packing (FIPG) material.

Apply seal packing to the timing gear cover as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3 to 5 mm (0.12 to 0.20 in.)

- NOTICE:

- Install the timing gear case within 3 minutes and tighten its bolts within 15 minutes as soon as application of FIPG is completed.

|

Install a new O-ring to the timing gear case.

|

Install the timing gear cover with the 14 bolts and 2 nuts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

|

| 28. INSTALL WATER PUMP ASSEMBLY |

|

Install a new gasket and the water pump with the 5 bolts and 2 nuts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

| 29. INSTALL CYLINDER HEAD SUB-ASSEMBLY |

|

- HINT:

- The cylinder head bolts are tightened in 3 progressive steps.

- If any bolt is broken or deformed, replace it.

Apply a light coat of engine oil on the threads and under the heads of the cylinder head bolts.

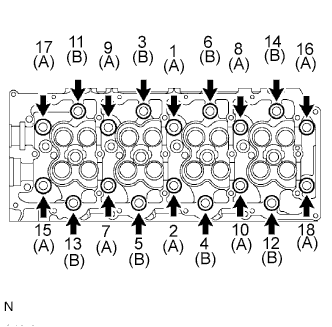

Install and uniformly tighten the 18 cylinder head bolts and 18 washers, in several passes in the sequence shown in the illustration.

- Torque:

- 85 N*m{867 kgf*cm, 63 ft.*lbf}

- HINT:

- Each bolt length is indicated below.

- Bolt length:

- 110 mm (4.33 in.) for bolt A

167 mm (6.57 in.) for bolt B

Mark the front of the cylinder head bolts with paint.

|

Further tighten the cylinder head bolts by 90° in the sequence shown in the illustration above.

Finally, tighten the cylinder head bolts by an additional 90°.

Check that the painted mark is now facing rearward.

| 30. INSTALL CAMSHAFT |

|

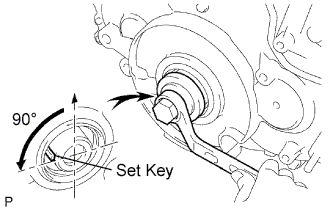

Using the crankshaft pulley bolt, set the No. 1 cylinder to 90° BTDC/compression.

- HINT:

- Set the No. 1 cylinder to 90° BTDC/compression to avoid interference with the piston top and valve head.

Install the camshaft.

Apply MP grease to the thrust portion of the camshaft.

Place the camshaft on the cylinder head, facing the key groove upward.

Align the timing marks (1 dot mark) of the camshaft drive and driven main gears, and set the No. 2 camshaft in place.

|

Remove any old packing (FIPG) material from the camshaft bearing cap.

|

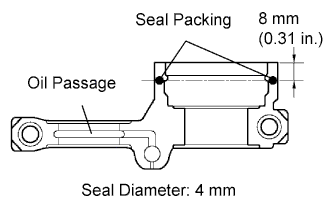

Apply seal packing to the specified areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 4 mm (0.16 in.)

- NOTICE:

- Do not allow FIPG to contact the oil passage of the bearing cap.

- After applying FIPG, install the camshaft bearing caps within 3 minutes and fasten the bolts within 15 minutes.

- Do not start the engine for at least 2 hours after the installation.

Install the 5 bearing caps in their proper locations.

Apply a light coat of engine oil on the threads and under the heads of the bearing cap bolts.

Install and uniformly tighten the 15 bearing cap bolts in several passes in the sequence shown in the illustration.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

Install the camshaft oil seal.

Apply MP grease to the lip of a new oil seal.

Using SST and a hammer, tap in the oil seal until its surface is flush with the oil seal retainer edge.

- SST

- 09608-06041

| 31. INSPECT AND ADJUST VALVE CLEARANCE |

| 32. INSTALL NO. 2 TIMING BELT COVER |

|

Apply seal packing (FIPG) to the specified areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- After applying FIPG, install the No. 2 timing belt cover within 3 minutes and tighten its bolts and nut within 15 minutes.

Install the No. 2 timing belt cover with the 4 bolts and nut.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 33. INSTALL CAMSHAFT TIMING PULLEY |

|

Install the camshaft timing pulley.

Fasten the bolt of the camshaft timing pulley by holding the camshaft with a wrench.

- Torque:

- 98 N*m{1,000 kgf*cm, 72 ft.*lbf}

| 34. INSTALL INJECTOR ASSEMBLY |

- NOTICE:

- Be sure to install the injector, No. 1 nozzle holder clamp, washer and bolt in their original positions.

Install 4 new injection nozzle seats to the cylinder head.

|

Apply a small amount of clean engine oil to 4 new O-rings.

Install an O-ring to each injector as shown in the illustration.

|

Insert the 4 injectors into the cylinder head.

- NOTICE:

- Insert the injector until it touches the injection nozzle seats surface.

- After installing the injector to the cylinder head, the O-ring may prevent the injector from fully seating. If so, pull out the injector and reinstall it.

- Always return an injector to the same place it was removed from.

For an injector that has been replaced with a new injector, register the injector compensation code (Toyota Fortuner RM0000012XK04BX_02_0003.html).

Temporarily install 4 new washers and the 4 No. 1 nozzle holder clamps with the 4 bolts.

- HINT:

- Apply a small amount of engine oil to the threads and under the heads of the clamp bolts.

- NOTICE:

The fork portion of the nozzle holder clamp must be set to the injector.

- Before tightening the bolts, check that the No. 1 nozzle holder clamp is set properly.

- To fasten the clamp bolts, first tighten them by hand until they cannot be turned further. Then, tighten the bolts to the specified torque at the following step.

- When tightening the bolts, pay attention not to tilt the bolt and the clamp.

- Do not reuse the washer.

- If the nozzle leakage pipe is accidentally tightened beyond the torque specification, it must be replaced.

|

Temporarily install the 4 injection pipes with the union nuts.

- HINT:

- To position the injectors, loosely tighten the union nut.

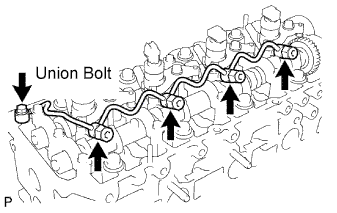

Check the nozzle leakage pipe. Check that there are no scratches or dents on the 5 union seal surfaces.

If scratches or dents are present, replace the nozzle leakage pipe.

|

Set the leakage pipe and 5 new gaskets in place.

|

Apply a small amount of oil to the 4 injector hollow screws and union bolt.

Temporarily install the leakage pipe with the 4 injector hollow screws and union bolt.

|

Tighten the 4 holder clamp bolts.

- Torque:

- 22 N*m{220 kgf*cm, 16 ft.*lbf}

Tighten the 4 injector hollow screws in order from 1 to 4.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

- NOTICE:

- If an injector hollow screw is accidentally tightened beyond the torque specification, it must be replaced.

|

Tighten the union bolt.

- Torque:

- 13 N*m{127 kgf*cm, 9 ft.*lbf}

- NOTICE:

- If the union bolt is accidentally tightened beyond the torque specification, it must be replaced.

Remove the 4 injection pipes.

| 35. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

|

Remove any old seal packing (FIPG) material from the cylinder head.

Apply seal packing to the specific areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surface.

- Install the belt cover within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the seal packing.

Install the gasket and cylinder head cover with the 10 bolts and 2 nuts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

Install 4 new nozzle holder seals.

| 36. INSTALL NOZZLE HOLDER SEAL |

Install 4 new holder seals.

| 37. INSTALL OIL FILLER CAP SUB-ASSEMBLY |

| 38. INSTALL NO. 1 TIMING BELT TENSIONER ASSEMBLY |

| 39. INSTALL NO. 1 TIMING BELT IDLER SUB-ASSEMBLY |

| 40. INSTALL TIMING BELT |

| 41. INSTALL NO. 1 TIMING BELT COVER |