Crankshaft Position Sensor -- Installation |

| 1. INSTALL CRANKSHAFT POSITION SENSOR |

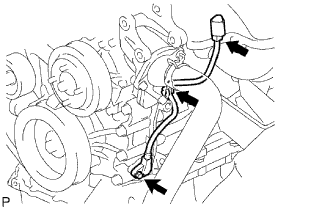

Apply a light coat of engine oil to the O-ring of the sensor.

|

Install the sensor with the bolt.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

Install the connector to the connector bracket.

Attach the harness clamp.

Connect the sensor connector.

| 2. INSTALL NO. 1 COMPRESSOR MOUNTING BRACKET |

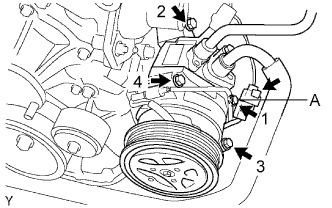

Temporarily install the mounting bracket with the 5 bolts.

- HINT:

- Make sure the flanges of the bolts are contacting the bracket surface.

|

Install the mounting bracket by tightening the 5 bolts in the order shown in the illustration.

- Torque:

- 24.5 N*m{250 kgf*cm, 18 ft.*lbf} for bolt A

- 45 N*m{459 kgf*cm, 33 ft.*lbf} for except bolt A

- NOTICE:

- In order to prevent misalignment, which causes belt rattle, tightening of the bolts must be performed in the order shown.

| 3. INSTALL COOLER COMPRESSOR ASSEMBLY |

|

Temporarily install the compressor with the bolt labeled A.

Install the compressor by tightening the 4 bolts in the order shown in the illustration.

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

- NOTICE:

- In order to prevent misalignment, which causes belt rattle, tightening of the bolts must be performed in the order shown.

Connect the compressor connector.

Install the suction hose with the 2 bolts.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

|

| 4. INSTALL DRIVE BELT |

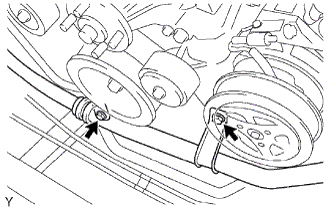

Install the drive belt to all the pulleys except the drive belt tensioner pulley.

|

Use the hexagon-shaped part indicated by the arrow in the illustration to move the tensioner pulley downward and then install the drive belt to the tensioner pulley.

- NOTICE:

- The backside of the drive belt should face the tensioner pulley.

- Check that the drive belt is properly set to each pulley.

After a new belt has been installed, check that the tensioner indicator mark is within range A shown in the illustration.

|

| 5. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |