CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO P2195, P2196, P2197 OR P2198)

READ VALUE USING INTELLIGENT TESTER (OUTPUT VOLTAGE OF A/F SENSOR)

INSPECT AIR FUEL RATIO SENSOR (HEATER RESISTANCE)

INSPECT A/F RELAY (Marking: A/F)

CHECK WIRE HARNESS (A/F SENSOR - ECM)

INSPECT FUEL INJECTOR ASSEMBLY

PERFORM CONFIRMATION DRIVING PATTERN

CHECK WHETHER DTC OUTPUT RECURS (DTC P2195, P2196, P2197 OR P2198)

CONFIRM IF VEHICLE HAS RUN OUT OF FUEL IN PAST

PERFORM CONFIRMATION DRIVING PATTERN

CHECK WHETHER DTC OUTPUT RECURS (DTC P2195, P2196, P2197, P2198)

PERFORM CONFIRMATION DRIVING PATTERN

CHECK WHETHER DTC OUTPUT RECURS (DTC P2195, P2196, P2197, P2198)

CONFIRM IF VEHICLE HAS RUN OUT OF FUEL IN PAST

DTC P2195 Oxygen (A/F) Sensor Signal Stuck Lean (Bank 1 Sensor 1) |

DTC P2196 Oxygen (A/F) Sensor Signal Stuck Rich (Bank 1 Sensor 1) |

DTC P2197 Oxygen (A/F) Sensor Signal Stuck Lean (Bank 2 Sensor 1) |

DTC P2198 Oxygen (A/F) Sensor Signal Stuck Rich (Bank 2 Sensor 1) |

DESCRIPTION

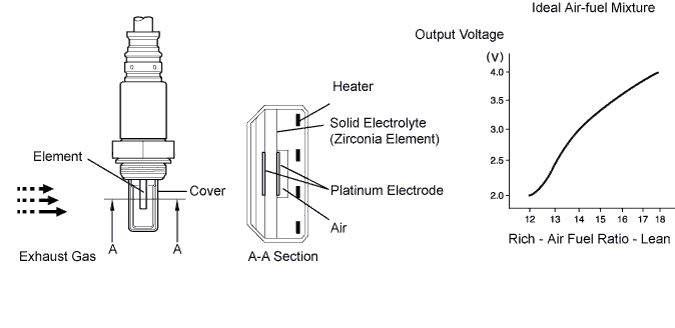

The Air-fuel Ratio (A/F) sensor generates voltage* in response to the actual air-fuel ratio. This sensor output voltage provide feedback to the ECM. The ECM uses the feedback to control the air-fuel ratio. Using the sensor output voltage, the ECM determines the deviation from the stoichiometric air-fuel ratio, and regulates the injection time. If the A/F sensor is malfunctioning, the ECM is unable to control the air-fuel ratio accurately.The A/F sensor is equipped with a heater which heats the zirconia element. The heater is also controlled by the ECM. When the intake air volume is low (the temperature of the exhaust gas is low), a current flows to the heater to heat the sensor to facilitate the detection of accurate oxygen concentration.

The A/F sensor is a planar type. Compared to the conventional type, the sensor and heater portions are narrower. The heat of the heater is conducted to the zirconia element through the alumina, accelerating sensor activation.

To obtain a high purification rate of carbon monoxide (CO), hydrocarbon (HC) and nitrogen oxide (NOx) in the exhaust gas, a Three-Way Catalytic Converter (TWC) is used. The TWC is most efficient when the air-fuel ratio is maintained near the stoichiometric air-fuel ratio.

- HINT:

- *: The voltage value changes inside the ECM only.

| DTC No. | DTC Detection Condition | Trouble Area |

| P2195 P2197 | Condition (a) continues for 10 seconds or more (a) A/F sensor voltage more than 3.8 V |

|

| P2195 P2197 | While fuel cut operation performed (during vehicle deceleration), A/F sensor current 3.6 mA or more for 3 seconds |

|

| P2196 P2198 | Condition (a) continues for 10 seconds or more (a) A/F sensor voltage less than 2.8 V |

|

| P2196 P2198 | While fuel cut operation performed (during vehicle deceleration), A/F sensor current 1.4 mA for 3 seconds (2 trip detection logic) |

|

- HINT:

- DTCs P2195 and P2196 indicate malfunctions related to bank 1 A/F sensor circuit.

- DTCs P2197 and P2198 indicate malfunctions related to bank 2 A/F sensor circuit.

- Bank 1 refers to the bank that includes the No. 1 cylinder.

- Bank 2 refers to the bank that includes the No. 2 cylinder.

- Sensor 1 refers to the sensor closest to the engine assembly.

- After confirming DTC P2195, P2196 , P2197 and P2198 use the intelligent tester to confirm the voltage output of A/F sensor (AFS B1 S1 / AFS B2 S1) from the Powertrain / Engine and ECT / Data List.

- The A/F sensor's output voltage and the short-term fuel trim value can be read using the intelligent tester.

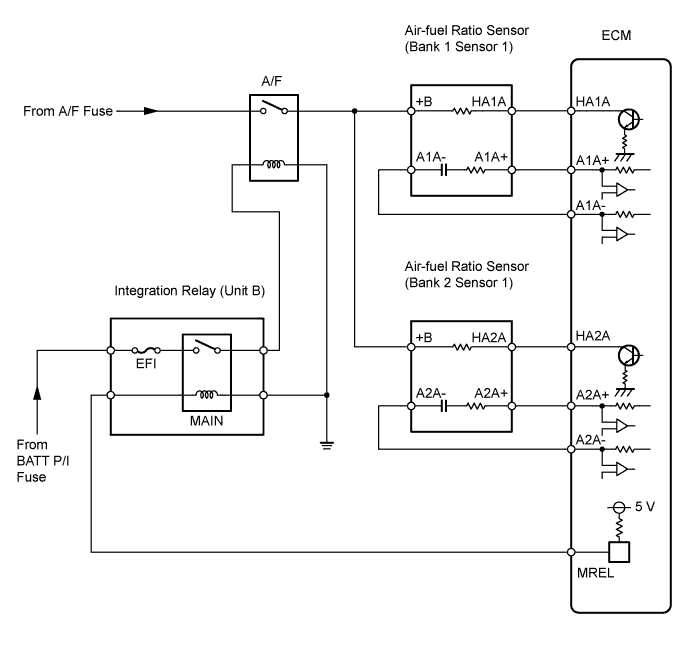

- The ECM controls the voltage of the A1A+, A2A+, A1A- and A2A- terminals of the ECM to the fixed voltage. Therefore, it is impossible to confirm the A/F sensor output voltage without the intelligent tester.

WIRING DIAGRAM

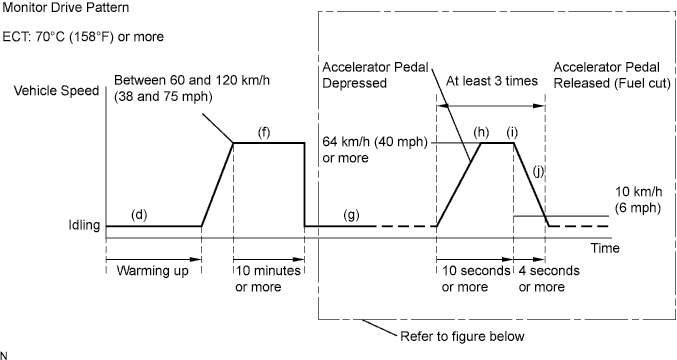

CONFIRMATION DRIVING PATTERN

This confirmation driving pattern is used in the following diagnostic troubleshooting inspection procedure when using an intelligent tester.

- (a) Connect the intelligent tester to the DLC3.

- (b) Turn the ignition switch ON and turn the tester ON.

- (c) Clear DTCs (Toyota Fortuner RM0000010E7004X.html).

- (d) Start the engine, and warm it up until the ECT reaches 70°C (158°F) or higher.

- (e) Enter the following menus to check the fuel cut status: Powertrain / Engine and ECT / Data List / Idle Fuel Cut.

- (f) Drive the vehicle between 60 km/h (38 mph) and 120 km/h (75 mph) for at least 10 minutes.

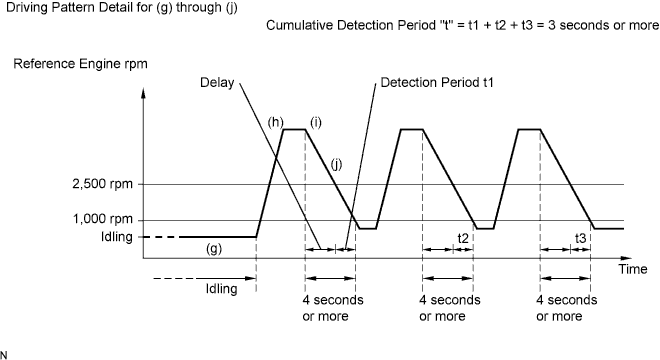

- (g) Change the transmission to 2nd gear.

- (h) Drive the vehicle at proper vehicle speed to perform fuel cut operation.

- HINT:

- Fuel cut is performed when the following conditions are met:

- Accelerator pedal fully released.

- Engine speed is 2,500 rpm or more (fuel injection returns at 1,000 rpm).

- (i) Accelerate the vehicle to 64 km/h (40 mph) or more by depressing the accelerator pedal for at least 10 seconds.

- (j) Soon after performing step (i) above, release the accelerator pedal for at least 4 seconds without depressing the brake pedal in order to execute fuel cut control.

- (k) Allow the vehicle to decelerate until the vehicle speed declines to less than 10 km/h (6 mph).

- (l) Repeat steps from (g) through (j) above at least 3 times in one driving cycle.

- HINT:

- Completion of all A/F sensor monitors is required to change the value in test result.

- CAUTION:

- Strictly observe posted speed limits, traffic laws, and road conditions when performing these drive patterns.

INSPECTION PROCEDURE

- HINT:

- Intelligent tester only:

- Malfunctioning areas can found by performing the Active Test / Control the Injection volume for A/F sensor operation. The "Control the injection volume for A/F sensor" operation can determine if the A/F sensor, heated oxygen sensor or other potential trouble areas are malfunctioning or not.

- HINT:

- "Control the injection volume for A/F sensor" is an Active Test which changes the injection volume to -12.5% or +25%.

- Connect the intelligent tester to the DLC3.

- Start the engine and turn the tester ON.

- Warm up the engine by running the engine at 2,500 rpm for approximately 90 seconds.

- Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the injection volume for A/F sensor.

- Enter the following monitor items: AFS B1S1 and O2S B1S2 or AFS B2S1 and O2S B2S2.

- Perform the "Control the injection volume for A/F sensor" operation with the engine in a idling condition (press the right or left button).

- HINT:

- The "Control the injection volume for A/F sensor" operation lowers the fuel injection volume by 12.5% or increases the injection volume by 25%.

- Each sensor reacts in accordance with increases and decreases in the fuel injection volume.

| Tester Display (Sensor) | Injection Volume | Status | Voltage |

| AFS B1S1 or AFS B2S1 (A/F) | +25% | Rich | Less than 3.0 V |

| AFS B1S1 or AFS B2S1 (A/F) | -12.5% | Lean | More than 3.35 V |

| O2S B1S2 or O2S B2S2 (heated oxygen sensor) | +25% | Rich | More than 0.55 V |

| O2S B1S2 or O2S B2S2 (heated oxygen sensor) | -12.5% | Lean | Less than 0.4 V |

- NOTICE:

- The A/F sensor has an output delay of a few seconds and the heated oxygen sensor has a maximum output delay of approximately 20 seconds.

| Case | A/F Sensor (Sensor 1) Output Voltage | Heated Oxygen Sensor (Sensor 2) Output Voltage | Main Suspected Trouble Areas | ||

| 1 | Injection volume +25% -12.5% |  | Injection volume +25% -12.5% |  | - |

| Output voltage More than 3.35 V Less than 3.0 V |  | Output voltage More than 0.55 V Less than 0.4 V |  | ||

| 2 | Injection volume +25% -12.5% |  | Injection volume +25% -12.5% |  |

|

| Output voltage Almost no reaction |  | Output voltage More than 0.55 V Less than 0.4 V |  | ||

| 3 | Injection volume +25% -12.5% |  | Injection volume +25% -12.5% |  |

|

| Output voltage More than 3.35 V Less than 3.0 V |  | Output voltage Almost no reaction |  | ||

| 4 | Injection volume +25% -12.5% |  | Injection volume +25% -12.5% |  |

|

| Output voltage Almost no reaction |  | Output voltage Almost no reaction |  | ||

- Following the A/F CONTROL procedure enables technicians to check and graph the voltage outputs of both the A/F and heated oxygen sensors.

- Enter the following menus on the tester: Powertrain / Engine and ECT / Active Test / Control the injection volume for A/F sensor and Data List / AFS B1S1 and O2S B1S2 or AFS B2S1 and O2S B2S2.

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

- These DTCs are related to the A/F sensor.

- These DTCs are recorded when A/F sensor has malfunction, although the caption is oxygen sensor.

| 1.CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO P2195, P2196, P2197 OR P2198) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

- Result:

Display (DTC output) Proceed to P2195, P2196, P2197 or P2198 A DTCs other than P2195, P2196, P2197 or P2198 B

- HINT:

- If any DTCs other than P2195, P2196, P2197 or P2198 are output, troubleshoot those DTCs first.

|

| ||||

| A | |

| 2.READ VALUE USING INTELLIGENT TESTER (OUTPUT VOLTAGE OF A/F SENSOR) |

Connect the intelligent tester to the DLC3.

Warm up the A/F sensors (bank 1, 2 sensor 1) with the engine at 2,500 rpm for approximately 90 seconds.

Read A/F sensor voltage output on the intelligent tester.

Enter the following menus: Powertrain / Engine and ECT / Data List.

Select AFS B1S1 or AFS B2S1 / Engine Speed.

Monitor the A/F sensor voltage carefully.

Check the A/F sensor voltage under the condition as follows.

(1) Allow engine to idle for 30 seconds.

(2) Engine is racing at approximately 2,500 rpm (when engine revolution is not suddenly changed).

(3) Raise the engine speed to 4,000 rpm and release the accelerator pedal fully closed quickly.- Standard:

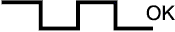

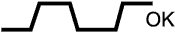

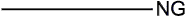

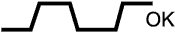

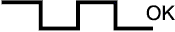

- Condition (1) and (2)

Voltage change in the vicinity of 3.3 V (between approximately 3.1 to 3.5 V) as shown in the illustration.

Condition (3)

A/F sensor voltage increases to 3.8 V or more during engine deceleration (when fuel cut) as shown in the illustration.

- HINT:

- Whenever the output voltage of the A/F sensor remains at approximately 3.3 V (see malfunction condition diagram) under any condition as well as the above conditions, the A/F sensor may have an open circuit. (this will also happen when the A/F sensor heater has an open circuit.)

- Whenever the output voltage of the A/F sensor remains at a certain value of approximately 3.8 V or more, or 2.8 V or less (see malfunction condition diagram) under any condition as well as the above conditions, the A/F sensor may have a short circuit.

- The ECM will stop fuel injection (fuel cut) during engine deceleration. This will cause a lean condition and should result in a momentary increase in the A/F sensor output voltage.

- The ECM must establish a closed throttle position learned value to perform fuel cut. If the battery terminal has been disconnected, the vehicle must be driven over (10 mph) to allow the ECM to learn the closed throttle position.

- When the vehicle is driven:

In the case that the output voltage of the A/F sensor is below 2.8 V during fuel enrichment (for example, when the vehicle tries to overtake another vehicle on a highway, the vehicle speed is suddenly increased with the accelerator pedal fully depressed), the A/F sensor is functioning normally. - The A/F sensor is a current output element, and therefore the current is converted into voltage inside the ECM. If measuring the voltage at connectors of the A/F sensor or ECM, you will obtain a constant voltage.

|

| ||||

| NG | |

| 3.INSPECT AIR FUEL RATIO SENSOR (HEATER RESISTANCE) |

|

Disconnect the A30 and A31 A/F sensor connectors.

Measure the resistance of the A/F sensor.

- Standard resistance:

Bank 1 Sensor 1 Tester Connection Condition Specified Condition 1 (HA1A) - 2 (+B) 20°C (68°F) 1.8 to 3.4 Ω 1 (HA1A) - 4 (A1A-) - 10 kΩ or higher Bank 2 Sensor 1 Tester Connection Condition Specified Condition 1 (HA2A) - 2 (+B) 20°C (68°F) 1.8 to 3.4 Ω 1 (HA2A) - 4 (A2A-) - 10 kΩ or higher

|

| ||||

| OK | |

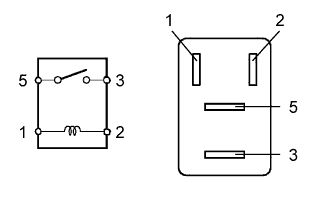

| 4.INSPECT A/F RELAY (Marking: A/F) |

|

Remove the relay from the engine room relay block.

Measure the resistance of the relay.

- Standard resistance:

Terminal No. Specified Condition 3 - 5 10 kΩ or higher 3 - 5 Below 1 Ω

(when battery voltage is applied to terminals 1 and 2)

|

| ||||

| OK | |

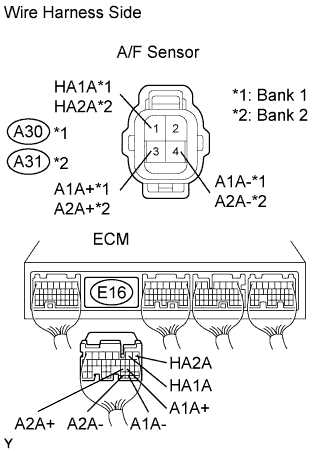

| 5.CHECK WIRE HARNESS (A/F SENSOR - ECM) |

|

Disconnect the A30 or A31 A/F sensor connectors.

Disconnect the E16 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Bank 1 Sensor 1 Terminal Connection Specified Condition A30-1 (HA1A) - E16-2 (HA1A) Below 1 Ω A30-3 (A1A+) - E16-22 (A1A+) Below 1 Ω A30-4 (A1A-) - E16-30 (A1A-) Below 1 Ω A30-1 (HA1A) or E16-2 (HA1A) - Body ground 10 kΩ or higher A30-3 (A1A+) or E16-22 (A1A+) - Body ground 10 kΩ or higher A30-4 (A1A-) or E16-30 (A1A-) - Body ground 10 kΩ or higher Bank 2 Sensor 1 Terminal Connection Specified Condition A31-1 (HA2A) - E16-1 (HA2A) Below 1 Ω A31-3 (A2A+) - E16-23 (A2A+) Below 1 Ω A31-4 (A2A-) - E16-31 (A2A-) Below 1 Ω A31-1 (HA1A) or E16-1 (HA2A) - Body ground 10 kΩ or higher A31-3 (A2A+) or E16-23 (A2A+) - Body ground 10 kΩ or higher A31-4 (A2A-) or E16-31 (A2A-) - Body ground 10 kΩ or higher

|

| ||||

| OK | |

| 6.CHECK AIR INDUCTION SYSTEM |

Check for vacuum leaks in the air induction system.

|

| ||||

| OK | |

| 7.CHECK FUEL PRESSURE |

Check fuel pressure (high or low fuel pressure).

|

| ||||

| OK | |

| 8.INSPECT FUEL INJECTOR ASSEMBLY |

Check injector injection (high or low fuel pressure).

|

| ||||

| OK | |

| 9.REPLACE AIR FUEL RATIO SENSOR |

| NEXT | |

| 10.PERFORM CONFIRMATION DRIVING PATTERN |

- HINT:

- Clear all DTCs prior to perform the confirmation driving pattern.

| NEXT | |

| 11.CHECK WHETHER DTC OUTPUT RECURS (DTC P2195, P2196, P2197 OR P2198) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the tester ON .

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

- Result:

Display Proceed to No output A P2195, P2196, P2197 or P2198 (A/F sensor pending DTCs) B

|

| ||||

| A | |

| 12.CONFIRM IF VEHICLE HAS RUN OUT OF FUEL IN PAST |

|

| ||||

| YES | ||

| ||

| 13.PERFORM CONFIRMATION DRIVING PATTERN |

- HINT:

- Clear all DTCs prior to performing the confirmation driving pattern.

| NEXT | |

| 14.CHECK WHETHER DTC OUTPUT RECURS (DTC P2195, P2196, P2197, P2198) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the tester ON .

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

- Result:

Display Proceed to No output A P2195, P2196, P2197 or P2198 (A/F sensor pending DTCs) B

|

| ||||

| A | |

| 15.REPLACE AIR FUEL RATIO SENSOR |

| NEXT | |

| 16.PERFORM CONFIRMATION DRIVING PATTERN |

- HINT:

- Clear all DTCs prior to performing the confirmation driving pattern.

| NEXT | |

| 17.CHECK WHETHER DTC OUTPUT RECURS (DTC P2195, P2196, P2197, P2198) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

- Result:

Display Proceed to No output A P2195, P2196, P2197 or P2198 (A/F sensor pending DTCs) B

|

| ||||

| A | |

| 18.CONFIRM IF VEHICLE HAS RUN OUT OF FUEL IN PAST |

|

| ||||

| YES | ||

| ||