READ VALUE USING INTELLIGENT TESTER (THROTTLE POSITION, THROTTLE POSITION NO. 2)

CHECK WIRE HARNESS (THROTTLE POSITION SENSOR - ECM)

CHECK IF DTC OUTPUT RECURS (THROTTLE POSITION SENSOR DTCS)

DTC P0120 Throttle / Pedal Position Sensor / Switch "A" Circuit |

DTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance Problem |

DTC P0122 Throttle / Pedal Position Sensor / Switch "A" Circuit Low Input |

DTC P0123 Throttle / Pedal Position Sensor / Switch "A" Circuit High Input |

DTC P0220 Throttle / Pedal Position Sensor / Switch "B" Circuit |

DTC P0222 Throttle / Pedal Position Sensor / Switch "B" Circuit Low Input |

DTC P0223 Throttle / Pedal Position Sensor / Switch "B" Circuit High Input |

DTC P2135 Throttle / Pedal Position Sensor / Switch "A" / "B" Voltage Correlation |

DESCRIPTION

- HINT:

- This Electronic Throttle Control System (ETCS) does not use a throttle cable.

- This throttle position sensor is a non-contact type.

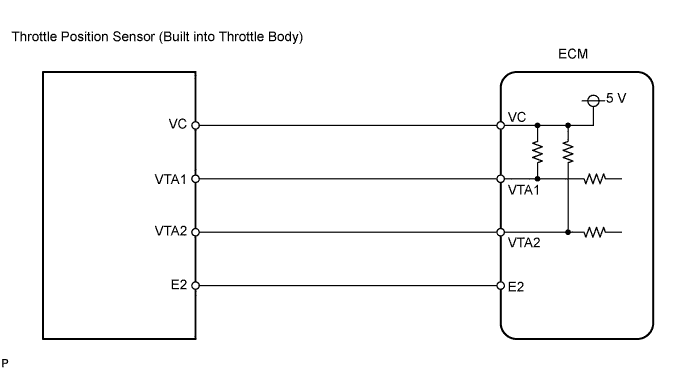

The ECM judges the actual opening angle of the throttle valve using signals input from terminals VTA1 and VTA2. Then the ECM controls the throttle motor, which controls the throttle valve angle properly in response to operation of the accelerator pedal.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0120 | Output voltage of VTA1 quickly fluctuates beyond lower and upper malfunction thresholds for 2 seconds (1 trip detection logic) |

|

| P0121 | Difference between VTA1 and VTA2 voltages is less than 0.8 V, or more than 1.6 V for 2 seconds. (1 trip detection logic) |

|

| P0122 | Output voltage of VTA1 0.2 V or less for 2 seconds (1 trip detection logic) |

|

| P0123 | Output voltage of VTA1 4.8 V or more for 2 seconds (1 trip detection logic) |

|

| P0220 | Output voltage of VTA2 quickly fluctuates beyond lower and upper malfunction thresholds for 2 seconds (1 trip detection logic) |

|

| P0222 | Output voltage of VTA2 0.5 V or less for 2 seconds (1 trip detection logic) |

|

| P0223 | Output voltage of VTA2 4.8 V or more, and VTA1 between 0.2 V and 1.8 V for 2 seconds (1 trip detection logic) |

|

| P2135 | Either condition (a) or (b) met (1 trip detection logic): (a) Difference between output voltages of VTA1 and VTA2 0.02 V or less for 0.5 seconds or more (b) Output voltage of VTA1 0.2 V or less, and VTA2 0.5 V or less, for 0.4 seconds or more |

|

- NOTICE:

- When a malfunction is detected, the throttle valve is locked at a certain opening angle. Also, all electronically controlled throttle operations are canceled until the system returns to normal and the ignition switch is turned OFF.

- HINT:

- When any of these DTCs is detected, check the throttle valve opening angle (Throttle Position and Throttle Position No. 2) using the intelligent tester.

- The Throttle Position is the VTA1 signal (expressed as a percentage), and Throttle Position No. 2 is the VTA2 signal (expressed as a voltage).

| Tester Display | Accelerator Pedal Fully Released | Accelerator Pedal Fully Depressed |

| Throttle Position | 10 to 24% | 64 to 96% |

| Throttle Position No. 2 | 2.1 to 3.1 V | 4.6 to 5.0 V |

MONITOR DESCRIPTION

The ECM uses the throttle position sensor to monitor the throttle valve opening angle. There are several checks that the ECM performs to confirm that the throttle position sensor is operating properly.- A specific voltage difference is expected between the sensor terminals, VTA1 and VTA2, for each throttle valve opening angle. If the difference between VTA1 and VTA2 is incorrect, the ECM interprets this as a malfunction in the sensor and stores a DTC.

- VTA1 and VTA2 each have a specific voltage range. If VTA1 or VTA2 is outside the normal operating range, the ECM interprets this as a malfunction in the sensor and stores a DTC.

- VTA1 and VTA2 should never be close to the same voltage level. If VTA1 is within 0.02 V of VTA2, the ECM determines that there is a short circuit in the sensor and stores a DTC.

- This sensor transmits two signals: VTA1 and VTA2. VTA1 is used to detect the throttle opening angle and VTA2 is used to detect malfunctions in VTA1. The ECM performs several checks to confirm that the throttle position sensor and VTA1 are operating properly.

For each throttle opening angle, a specific voltage difference is expected between the outputs of VTA1 and VTA2. If the output voltage difference between the two signals deviates from the normal operating range, the ECM interprets this as a malfunction of the throttle position sensor. The ECM illuminates the MIL and stores the DTC.

If the malfunction is not repaired successfully, the DTC is stored 2 seconds after the engine is next started.

FAIL-SAFE

If the ETCS is malfunctioning, the ECM cuts off the current to the throttle actuator. The throttle control valve returns to a predetermined throttle position (approximately 6°) by the force of the return spring.Then, required engine power is calculated by using the ignition timing and accelerator pedal position. The engine is controlled by intermittent fuel cut.

If the accelerator pedal is depressed firmly and slowly, the vehicle can be driven at minimum speed. If the accelerator pedal is depressed quickly, the vehicle may speed up and slow down erratically.

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- If DTCs related to different systems that have terminal E2 as the ground terminal are output simultaneously, terminal E2 may have an open circuit.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

- These DTCs are related to the throttle position sensor.

| 1.READ VALUE USING INTELLIGENT TESTER (THROTTLE POSITION, THROTTLE POSITION NO. 2) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Throttle Position and Throttle Position No. 2.

Read the values.

- Result:

TP (VTA1)

When AP ReleasedTP No. 2 (VTA2)

When AP ReleasedTP (VTA1)

When AP DepressedTP No. 2 (VTA2)

When AP DepressedSuspected Area Proceed to 0% 0 to 0.2 V 0% 0 to 0.2 V VC circuit open A 100% 4.5 to 5.0 V 100% 4.5 to 5.0 V E2 circuit open A 0 or 100% 2.1 to 3.1 V

(fail-safe)0 or 100% 2.1 to 3.1 V

(fail-safe)VTA1 circuit open or ground short A 10 to 24%

(fail-safe)0 to 0.2 V,

or 4.5 to 5.0 V10 to 24%

(fail-safe)0 to 0.2 V,

or 4.5 to 5.0 VVTA2 circuit open or ground short A 10 to 24% 2.1 to 3.1 V 64 to 96%

(not fail-safe)4.6 to 5.0 V

(not fail-safe)Throttle position sensor circuit is normal B

- HINT:

- If DTC P0121 is output, proceed to "Check Wire Harness (Throttle Position Sensor - ECM)".

- TP stands for throttle position, and AP stands for accelerator pedal.

- VTA1 is expressed as a percentage, and VTA2 is expressed as a voltage.

|

| ||||

| A | |

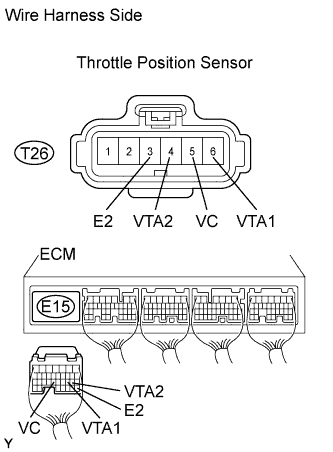

| 2.CHECK WIRE HARNESS (THROTTLE POSITION SENSOR - ECM) |

|

Disconnect the T26 throttle body connector.

Disconnect the E15 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection Specified Condition T26-5 (VC) - E15-23 (VC) Below 1 Ω T26-6 (VTA1) - E15-20 (VTA1) Below 1 Ω T26-4 (VTA2) - E15-19 (VTA2) Below 1 Ω T26-3 (E2) - E15-28 (E2) Below 1 Ω T26-5 (VC) or E15-23 (VC) -Body ground 10 kΩ or higher T26-6 (VTA1) or E15-20 (VTA1) - Body ground 10 kΩ or higher T26-4 (VTA2) or E15-19 (VTA2) - Body ground 10 kΩ or higher

|

| ||||

| OK | |

| 3.CHECK ECM (VC VOLTAGE) |

|

Disconnect the throttle body connector.

Turn the ignition switch ON.

Measure the voltage of the ECM connector.

- Standard voltage:

Tester Connection Specified Condition E15-23 (VC) - E15-28 (E2) 4.5 to 5.0 V

|

| ||||

| OK | |

| 4.REPLACE THROTTLE BODY |

| NEXT | |

| 5.CHECK IF DTC OUTPUT RECURS (THROTTLE POSITION SENSOR DTCS) |

Clear the DTCs (Toyota Fortuner RM0000010E700JX.html).

Start the engine.

Idle engine for 15 seconds or more.

Connect the intelligent tester to the DLC3.

Turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

- Result:

Display (DTC output) Proceed to P0120, P0121, P0122, P0123, P0220, P0222, P0223 and/or P2135 A No output B

|

| ||||

| A | ||

| ||