DTC P0200 Injector Circuit / Open

Description

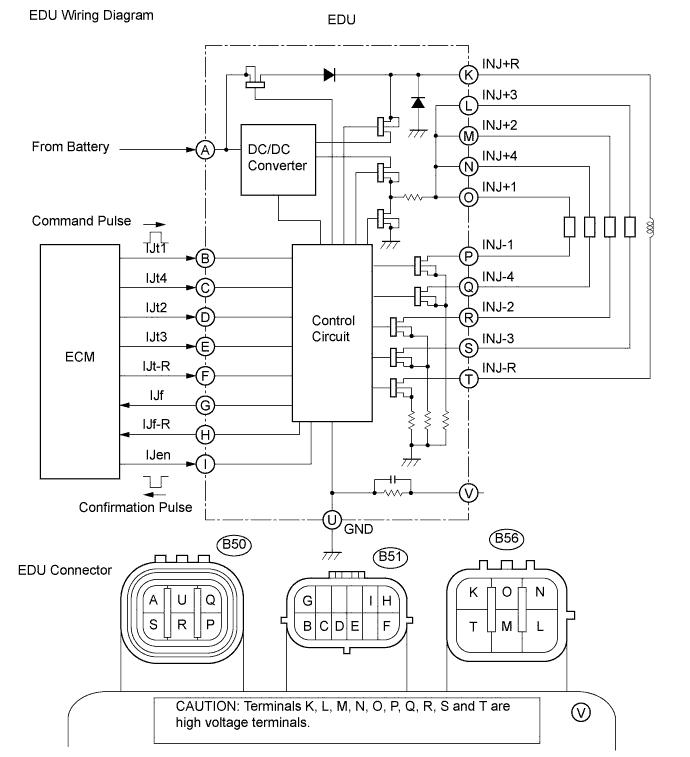

The EDU drives the injectors at high speeds. The EDU delivers high-speed drive signals under high-pressure fuel conditions using the DC/DC converter, which provides a high-voltage and quick-charging system.

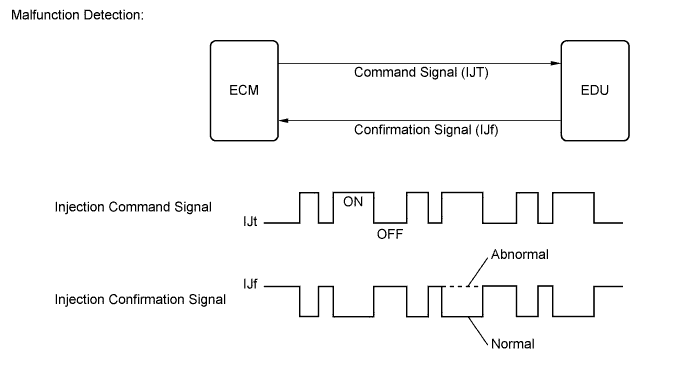

Soon after the EDU receives an injection command (#) signal from the ECM, the EDU responds to the command with an injector injection confirmation (INJF) signal when the current is applied to the injector.

Toyota fault code list DTC P0200 2AD-FHV

| DTC No. |

DTC Detection Condition |

Trouble Area |

| P0200 |

Open or short in EDU or injector circuit

After engine is started, there is no INJF signal from EDU to ECM, despite ECM sending # signals to EDU

(1 trip detection logic) |

- Open or short in EDU circuit

- Injector

- EDU

- ECM

|

HINT:

DTC P0200 is detected when starting the engine and letting it idle for 30 seconds.

Monitor description

- P0200 (Open or short in EDU or injector circuit):

The ECM continuously monitors both injection command (#) signals and injection confirmation (INJF) signals. This DTC will be set if the ECM determines that the number of # signals and INJF signals are inconsistent.

The injectors are grounded over a Field Effect Transistor (FET) and a serial resistor. This resistor creates a voltage drop, which is monitored by the EDU (injector drive circuit), in relation to the current drawn by the injector. When the injector current becomes too high, the voltage drop over the resistor exceeds a specified level and no INJF signal for that cylinder is sent to the ECM.

P0200 refers to a malfunction in the EDU or injector circuit.

If this DTC is set, the ECM enters fail-safe mode and limits engine power or stops the engine. The fail-safe mode continues until the ignition switch is turned off.

Monitor strategy

| Required sensors |

INJF signal from EDU |

| Frequency of operation |

Continuous |

| Duration |

10 seconds |

| MIL operation |

1 driving cycle |

Typical enabling conditions

| Item |

Specification |

Specification |

| Minimum |

Maximum |

| Engine speed |

500 rpm |

- |

| Battery voltage |

11 V |

- |

| Ignition switch |

on (IG) |

on (IG) |

Typical malfunction thresholds

| Threshold |

| The injection missing counter* for all the cylinders, or for one individual cylinder, reaches a specified number (taking approximately 1 second after starting the engine)

*: Increments when no INJF signal is received from the EDU despite the ECM sending # signals |

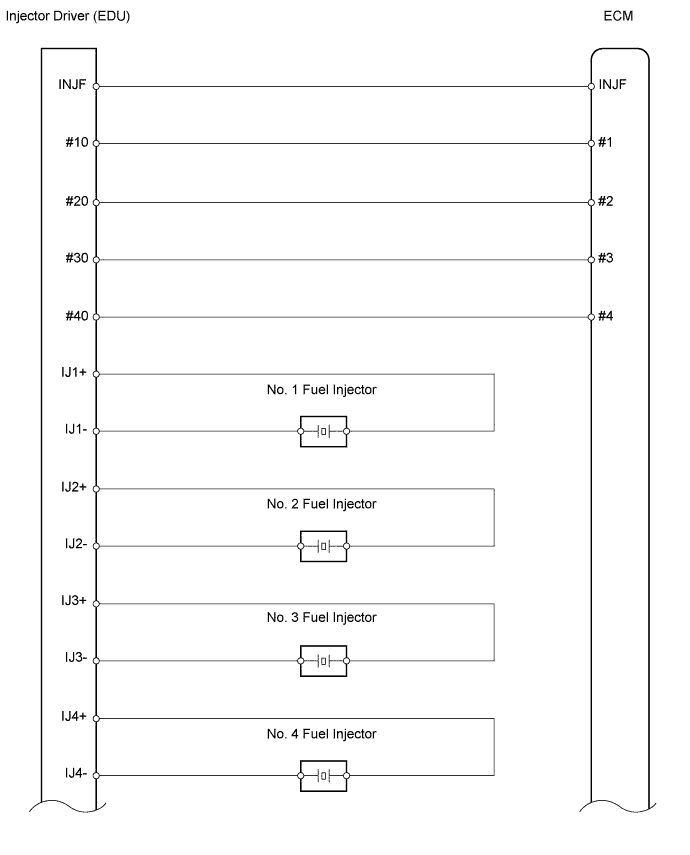

Wiring diagram

Inspection procedure

NOTICE:

- After replacing the ECM, the new ECM needs registration .

- After replacing an injector, the ECM needs registration .

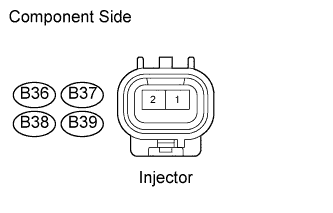

| 1.INSPECT INJECTOR ASSEMBLY |

-

Disconnect the B36, B37, B38, and B39 injector connectors.

-

Measure the resistance of the injector.

Standard resistance:

| Tester Connection |

Condition |

Specified Condition |

| 1 - 2 |

20°C (68°F) |

0.9 to 1.1 M? |

-

Reconnect the injector connectors.

|

|

| REPLACE INJECTOR ASSEMBLY |

|

| |

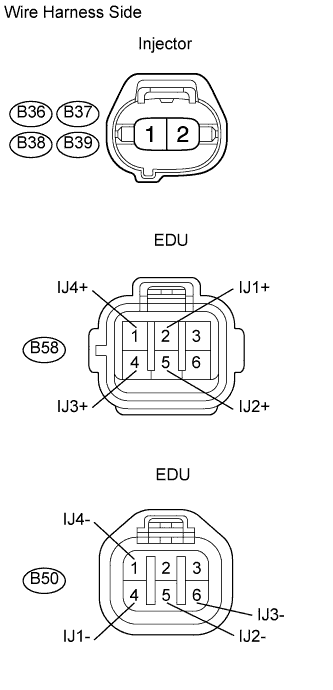

| 2.CHECK WIRE HARNESS (INJECTOR - EDU) |

-

Disconnect the B36, B37, B38, and B39 injector connectors.

-

Disconnect the B50 and B58 EDU connectors.

-

Measure the resistance of the wire harness side connectors.

Standard resistance:

| Tester Connection |

Specified Condition |

| B36-1 - B58-2 (IJ1+) |

Below 1 ? |

| B37-1 - B58-5 (IJ2+) |

Below 1 ? |

| B38-1 - B58-4 (IJ3+) |

Below 1 ? |

| B39-1 - B58-1 (IJ4+) |

Below 1 ? |

| B36-2 - B50-4 (IJ1-) |

Below 1 ? |

| B37-2 - B50-5 (IJ2-) |

Below 1 ? |

| B38-2 - B50-6 (IJ3-) |

Below 1 ? |

| B39-2 - B50-1 (IJ4-) |

Below 1 ? |

| B36-1 or B58-2 (IJ1+) - Body ground |

10 k? or higher |

| B37-1 or B58-5 (IJ2+) - Body ground |

10 k? or higher |

| B38-1 or B58-4 (IJ3+) - Body ground |

10 k? or higher |

| B39-1 or B58-1 (IJ4+) - Body ground |

10 k? or higher |

| B36-2 or B50-4 (IJ1-) - Body ground |

10 k? or higher |

| B37-2 or B50-5 (IJ2-) - Body ground |

10 k? or higher |

| B38-2 or B50-6 (IJ3-) - Body ground |

10 k? or higher |

| B39-2 or B50-1 (IJ4-) - Body ground |

10 k? or higher |

-

Reconnect the injector connectors.

-

Reconnect the EDU connectors.

|

|

| REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

| |

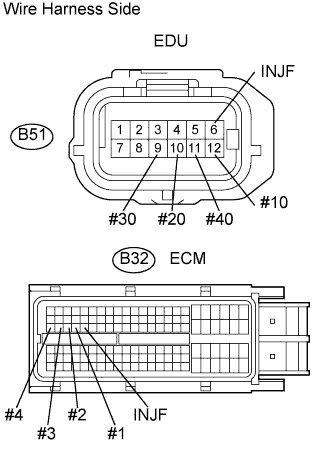

| 3.CHECK WIRE HARNESS (EDU - ECM) |

-

Disconnect the B51 EDU connector.

-

Disconnect the B32 ECM connector.

-

Measure the resistance of the wire harness side connectors.

Standard resistance:

| Tester Connection |

Specified Condition |

| B51-12 (#10) - B32-50 (#1) |

Below 1 ? |

| B51-10 (#20) - B32-49 (#2) |

Below 1 ? |

| B51-9 (#30) - B32-48 (#3) |

Below 1 ? |

| B51-11 (#40) - B32-47 (#4) |

Below 1 ? |

| B51-6 (INJF) - B32-51 (INJF) |

Below 1 ? |

| B51-12 (#10) or B32-50 (#1) - Body ground |

10 k? or higher |

| B51-10 (#20) or B32-49 (#2) - Body ground |

10 k? or higher |

| B51-9 (#30) or B32-48 (#3) - Body ground |

10 k? or higher |

| B51-11 (#40) or B32-47 (#4) - Body ground |

10 k? or higher |

| B51-6 (INJF) or B32-51 (INJF) - Body ground |

10 k? or higher |

-

Reconnect the EDU connector.

-

Reconnect the ECM connector.

|

|

| REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

| |

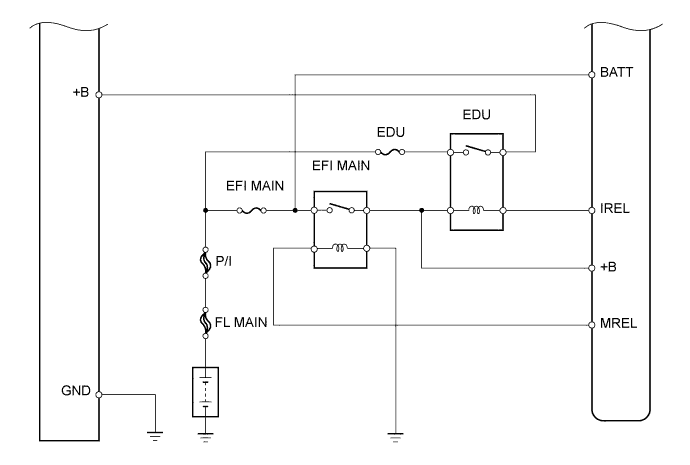

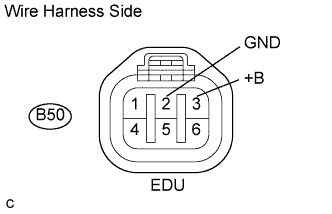

-

Disconnect the B50 EDU connector.

-

Turn the ignition switch on (IG).

-

Measure the voltage of the wire harness side connector.

Standard voltage:

| Tester Connection |

Specified Condition |

| B50-3 (+B) - B50-2 (GND) |

9 to 14 V |

-

Reconnect the EDU connector.

|

|

| CHECK EDU POWER SOURCE CIRCUIT |

|

| |

-

Replace the EDU.

| 6.CHECK WHETHER DTC OUTPUT RECURS |

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG) and turn the tester ON.

-

Clear DTCs

-

Start the engine and drive the vehicle for approximately 15 minutes.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read the DTCs.

Result:

| Display (DTC Output) |

Proceed to |

| P0200 |

A |

| No output |

B |