Wiper And Washer System (W/ Rain Sensor) - Headlight Signal Circuit

DESCRIPTION

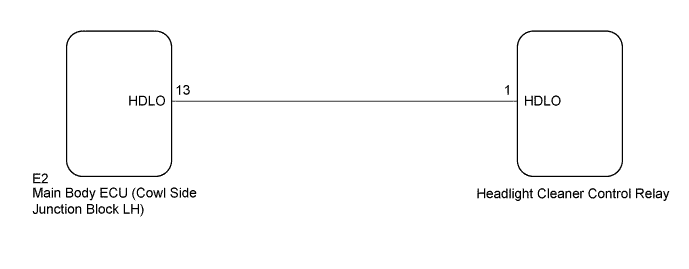

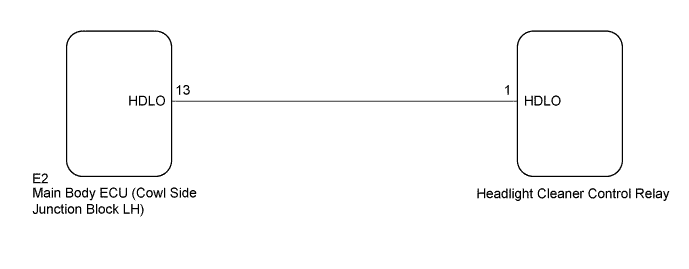

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK LOW BEAM HEADLIGHTS OPERATION

CHECK HARNESS AND CONNECTOR (HEADLIGHT CLEANER CONTROL RELAY - MAIN BODY ECU)

CHECK MAIN BODY ECU (COWL SIDE JUNCTION BLOCK LH)

WIPER AND WASHER SYSTEM (w/ Rain Sensor) - Headlight Signal Circuit

DESCRIPTION

The headlight cleaner control relay detects the low beam headlights status.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK LOW BEAM HEADLIGHTS OPERATION |

Check that the low beam headlights operate normally ().

- OK:

- Low beam headlights operate normally.

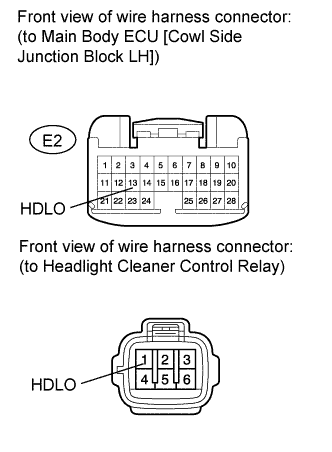

| 2.CHECK HARNESS AND CONNECTOR (HEADLIGHT CLEANER CONTROL RELAY - MAIN BODY ECU) |

Disconnect the E2 main body ECU (cowl side junction block LH) connector.

Disconnect the headlight cleaner control relay connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| 1 (HDLO) - E2-13 (HDLO) | Always | Below 1 Ω |

| 1 (HDLO) - Body ground | Always | 10 kΩ or higher |

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

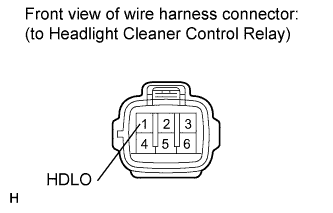

| 3.CHECK MAIN BODY ECU (COWL SIDE JUNCTION BLOCK LH) |

Disconnect the headlight cleaner control relay connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

| Tester Connection | Switch Condition | Specified Condition |

| 1 (HDLO) - Body ground | Engine switch on (IG)

Headlight dimmer switch in HEAD | 11 to 14 V |

| 1 (HDLO) - Body ground | Engine switch on (IG)

Headlight dimmer switch not in HEAD | Below 1 V |

| | REPLACE MAIN BODY ECU (COWL SIDE JUNCTION BLOCK LH) |

|

|

| OK | |

| |

| PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE ()

|

|