Turbocharger -- Installation |

| 1. CLEAN TURBOCHARGER SUB-ASSEMBLY |

| 2. INSTALL TURBOCHARGER SUB-ASSEMBLY |

|

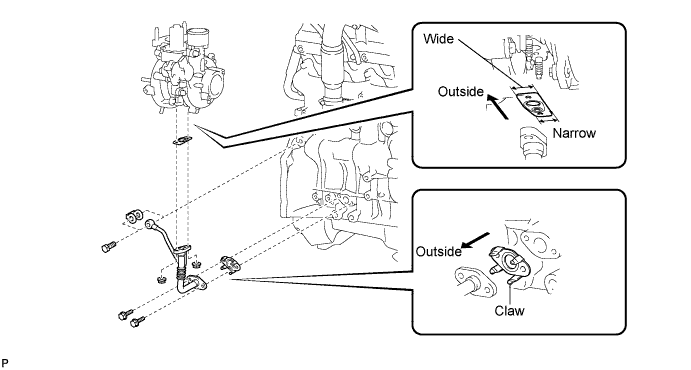

Temporarily install a new gasket and the turbocharger with 3 new nuts.

- HINT:

- When installing the turbo oil pipe, loosely install the 3 nuts so that the turbocharger and cylinder head can be aligned easily.

Temporarily install the turbo oil pipe.

- HINT:

- Before installing the oil pipe, clean it.

Install a new gasket and the oil pipe with the 2 nuts, but only loosely install the nuts.

- NOTICE:

- The notch (narrow part) of the gasket must face the engine.

Install a new gasket and the oil pipe with the 2 bolts, but only loosely install the bolts.

- NOTICE:

- The claws of the gasket must face the pipe.

Install a new gasket and the oil pipe with the union bolt, but only loosely install the union bolt.

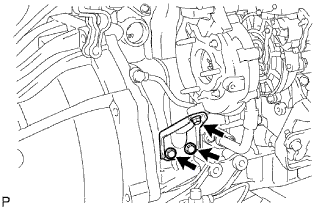

Temporarily install the turbocharger stay with the 3 bolts.

Tighten the 3 nuts of the turbocharger.

- Torque:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

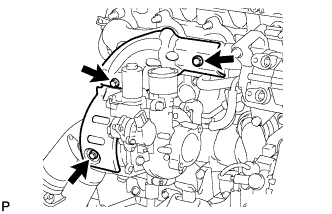

Tighten the 2 nuts and 2 bolts of the oil pipe, and the union bolt.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf} for bolt

- Torque:

- 13 N*m{133 kgf*cm, 9 ft.*lbf} for nut

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf} for union bolt

Tighten the 3 bolts of the turbocharger stay.

- Torque:

- 24 N*m{245 kgf*cm, 18 ft.*lbf}

| 3. INSTALL TURBINE OUTLET ELBOW |

Install a new gasket and the outlet elbow with the 3 nuts.

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

|

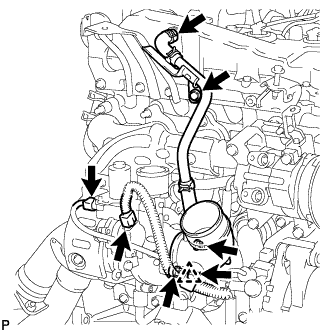

| 4. INSTALL NO. 1 TURBO WATER HOSE |

|

Connect the 2 hoses to the 2 tubes.

Move the 2 clamps to the locations where the hoses and tubes are connected.

| 5. INSTALL NO. 1 TURBO INSULATOR |

|

Temporarily install the turbo insulator with the bolt.

| 6. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Temporarily install the heat insulator with the 2 bolts.

Tighten the bolt of the turbo insulator, and the 2 bolts of the heat insulator.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

| 7. INSTALL COMPRESSOR INLET ELBOW |

|

Install a new gasket and inlet elbow with the 2 nuts.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

Connect the ventilation pipe to the cylinder head cover.

Move the clamp to the joint pipe of the hose.

Install the ventilation pipe with the bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Connect the 2 connectors to the turbocharger.

Install the harness clamp's clip to the inlet elbow.

| 8. INSTALL CHARGE AIR COOLER WITH INTAKE AIR CONNECTOR |

Install the charge air cooler with intake air connector (Toyota Fortuner RM0000015B6002X.html).

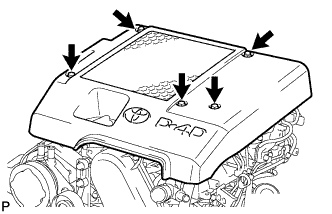

| 9. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY |

Install the cover with the 3 bolts and 2 nuts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

|

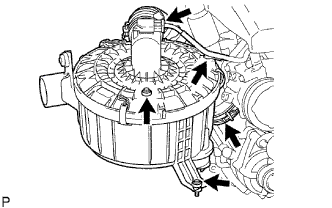

| 10. INSTALL AIR CLEANER ASSEMBLY |

|

Connect the air cleaner hose.

Install the cleaner with the 2 bolts.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

Tighten the hose clamp of the compressor inlet elbow.

Connect the MAF meter connector and install the clamp.

| 11. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

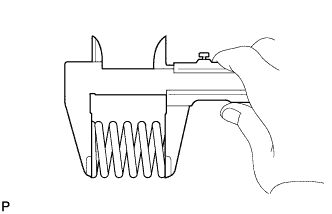

Using a vernier caliper, measure the free length of the compression spring.

- Minimum length:

- 40 mm (1.57 in.)

|

Install the front pipe to the pipe support.

Install a new gasket to the outlet pipe.

- NOTICE:

- Be careful with the installation direction of the gasket.

- Do not reuse the gasket.

- To ensure a proper seal, do not use the front pipe to force the gasket onto the outlet pipe.

- HINT:

- Using a plastic-faced hammer, uniformly strike the gasket so that the gasket and outlet pipe are properly fit.

|

Install the front pipe with the 2 compression springs and 2 bolts. Alternately tighten the bolts in several passes.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

| 12. INSTALL FRONT FENDER APRON SEAL UPPER |

2WD

Install the apron seal with the 6 clips.

4WD

Install the apron seal with the 5 clips.

| 13. INSTALL FRONT FENDER SEAL |

Install the seal with the 5 clips.

| 14. INSTALL FRONT WHEEL RH |

| 15. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 16. ADD ENGINE COOLANT |

Tighten the radiator drain cock plug by hand.

Tighten the cylinder block drain cock plug.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

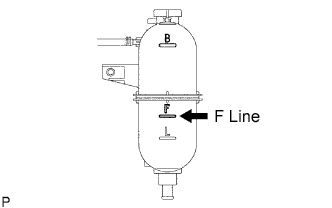

Fill the radiator with TOYOTA Super Long Life Coolant (SLLC) to the reservoir tank's B line.

- Standard Capacity:

Item Specified Condition Manual transmission 9.8 liters (10.4 US qts, 8.6 Imp. qts) Automatic transmission 11.1 liters (11.7 US qts, 9.8 Imp. qts)

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology is a combination of low phosphates and organic acids).

- Please contact your TOYOTA dealer for further details.

- NOTICE:

- Never use water as a substitute for engine coolant.

|

Press the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level drops below the B line, add TOYOTA SLLC to the B line.

Install the radiator reservoir cap.

Using a wrench, install the vent plug.

- Torque:

- 2.0 N*m{20 kgf*cm, 18 in.*lbf}

|

Bleed air from the cooling system.

Warm up the engine until the thermostat opens. While the thermostat is open, circulate the coolant for several minutes.

Maintain the engine speed at 2,500 to 3,000 rpm.

Press the inlet and outlet radiator hoses several times by hand to bleed air.

- CAUTION:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine and wait until the coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator reservoir cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

After the coolant cools down, check that the coolant level is at the F line.

If the coolant level is below the F line, add TOYOTA SLLC to the F line.

|

| 17. CHECK FOR ENGINE COOLANT LEAKS |

| 18. CHECK FOR ENGINE OIL LEAKS |