DESCRIPTION

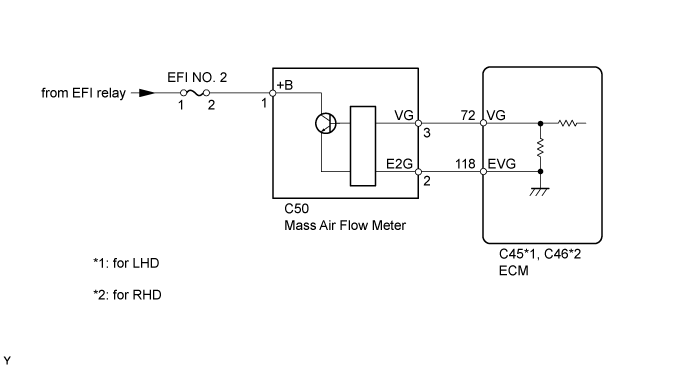

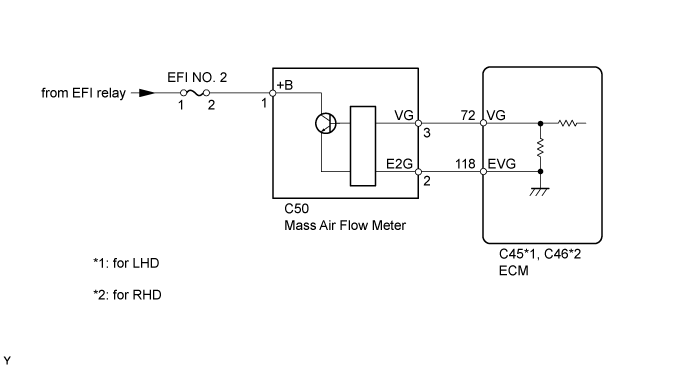

WIRING DIAGRAM

INSPECTION PROCEDURE

READ VALUE USING INTELLIGENT TESTER (MASS AIR FLOW RATE)

INSPECT MASS AIR FLOW METER (POWER SOURCE CIRCUIT)

INSPECT MASS AIR FLOW METER

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM)

INSPECT FUSE (EFI NO. 2)

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ENGINE ROOM RELAY BLOCK)

CHECK HARNESS AND CONNECTOR (ENGINE ROOM RELAY BLOCK)

CHECK HARNESS AND CONNECTOR (SENSOR GROUND)

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM)

REPLACE ECM

REPLACE MASS AIR FLOW METER

REPAIR OR REPLACE HARNESS OR CONNECTOR

CHECK FOR SHORTS IN ALL HARNESSES AND CONNECTORS CONNECTED TO FUSE AND REPLACE FUSE

CHECK ECM POWER SOURCE CIRCUIT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P0100 Mass or Volume Air Flow Circuit

DTC P0102 Mass or Volume Air Flow Circuit Low Input

DTC P0103 Mass or Volume Air Flow Circuit High Input

DESCRIPTION

The Mass Air Flow (MAF) meter uses a platinum hot wire. The mass air flow meter consists of a platinum hot wire, a temperature sensor and a control circuit installed in a plastic housing. The mass air flow meter hot wire and temperature sensor (located in the intake air by-pass of the housing) detect changes in the intake air temperature.

The hot wire is maintained at the predetermined temperature by controlling the current flow through the hot wire. This current flow is then used as the output voltage of the mass air flow meter.

The circuit is constructed so that the platinum hot wire and temperature sensor provide a bridge circuit, with the power transistor controlled so that the potential of A and B remains equal to maintain the predetermined temperature.

P0100| DTC Detection Drive Pattern | DTC Detection Condition | Trouble Area |

| Ignition switch ON for 3 seconds | Mass air flow (MAF) meter voltage is 0.2 V or less, or 4.9 V or more with the engine speed at 4000 rpm or less for 3 seconds (1 trip detection logic). | Open or short in Mass Air Flow (MAF) meter circuit

Mass air flow meter

ECM

|

P0102| DTC Detection Drive Pattern | DTC Detection Condition | Trouble Area |

| Ignition switch ON for 3 seconds | MAF meter voltage is 0.2 V or less with the engine speed at 4000 rpm or less for 3 seconds (1 trip detection logic). | Open in Mass Air Flow (MAF) meter circuit

Mass air flow meter

ECM

|

P0103| DTC Detection Drive Pattern | DTC Detection Condition | Trouble Area |

| Ignition switch ON for 3 seconds | MAF meter voltage is 4.9 V or more with the engine speed at 4000 rpm or less for 3 seconds (1 trip detection logic). | Shot in Mass Air Flow (MAF) meter circuit

Mass air flow meter

ECM

|

Related Data List| DTC No. | Data List |

| P0100 | MAF |

| P0102 |

| P0103 |

If DTC P0100, and/or P0102 is stored, the following symptoms may appear (as the ECU mistakenly determines that there is less air than the actual intake air amount, EGR is decreased to match the target EGR):

If DTC P0100, and/or P0103 is stored, the following symptoms may appear (as the ECU mistakenly determines that there is more air than the actual intake air amount, EGR is increased to match the target EGR):

Misfire

White smoke

Black smoke

After confirming DTC P0100, P0102 or P0103, check the mass air flow ratio by entering the following menus: Powertrain / Engine / Data List / MAF.

Reference:| Air Flow Value (g/sec.) | Malfunction |

| Approximately 0.0 | Open in mass air flow meter power source circuit

Open or short in VG circuit

|

| 174.0 or more | Open in EVG circuit |

WIRING DIAGRAM

INSPECTION PROCEDURE

- After replacing the ECM, the new ECM needs registration () and initialization ().

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.READ VALUE USING INTELLIGENT TESTER (MASS AIR FLOW RATE) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the tester on.

Enter the following menus: Powertrain / Engine / Data List / MAF.

Read the value.

Result| Result | Proceed to |

| 0.0 | A |

| 174.0 or more | B |

| Between 1 and 173.0* | C |

- *: The value should change when the throttle valve is opened or closed.

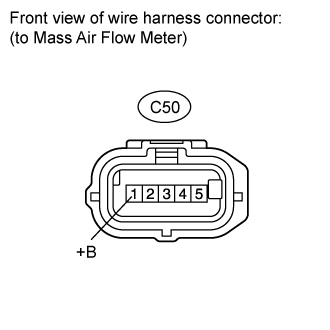

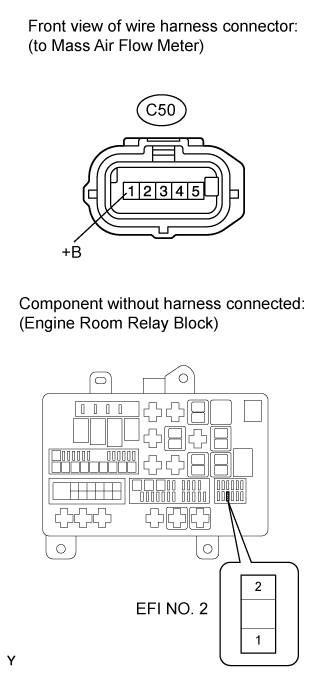

| 2.INSPECT MASS AIR FLOW METER (POWER SOURCE CIRCUIT) |

Disconnect the mass air flow meter connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

| Tester Connection | Switch Condition | Specified Condition |

| C50-1 (+B) - Body ground | Ignition switch ON | 11 to 14 V |

| 3.INSPECT MASS AIR FLOW METER |

Inspect the mass air flow meter ().

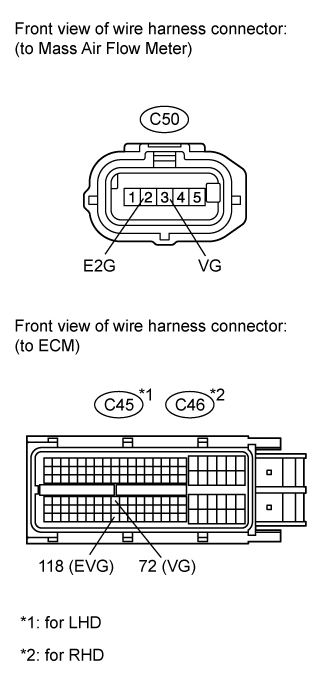

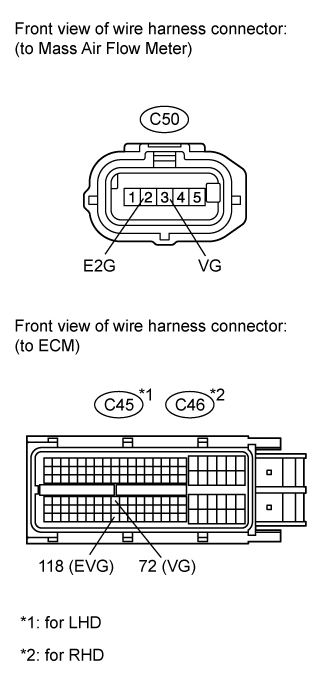

| 4.CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM) |

Disconnect the mass air flow meter connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

for LHD| Tester Connection | Condition | Specified Condition |

| C50-3 (VG) - C45-72 (VG) | Always | Below 1 Ω |

| C50-2 (E2G) - C45-118 (EVG) | Always | Below 1 Ω |

for RHD| Tester Connection | Condition | Specified Condition |

| C50-3 (VG) - C46-72 (VG) | Always | Below 1 Ω |

| C50-2 (E2G) - C46-118 (EVG) | Always | Below 1 Ω |

- Standard Resistance (Check for Short):

for LHD| Tester Connection | Condition | Specified Condition |

| C50-3 (VG) or C45-72 (VG) - Body ground | Always | 10 kΩ or higher |

for RHD| Tester Connection | Condition | Specified Condition |

| C50-3 (VG) or C46-72 (VG) - Body ground | Always | 10 kΩ or higher |

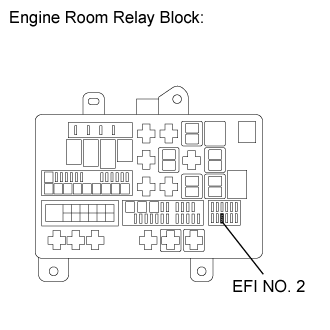

| 5.INSPECT FUSE (EFI NO. 2) |

Remove the EFI NO. 2 fuse from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| EFI NO. 2 fuse | Always | Below 1 Ω |

| 6.CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ENGINE ROOM RELAY BLOCK) |

Disconnect the mass air flow meter connector.

Remove the EFI NO. 2 fuse from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

| Tester Connection | Condition | Specified Condition |

| C50-1 (+B) - EFI NO. 2 fuse (2) | Always | Below 1 Ω |

- Standard Resistance (Check for Short):

| Tester Connection | Condition | Specified Condition |

| C50-1 (+B) or EFI NO. 2 fuse (2) - Body ground | Always | 10 kΩ or higher |

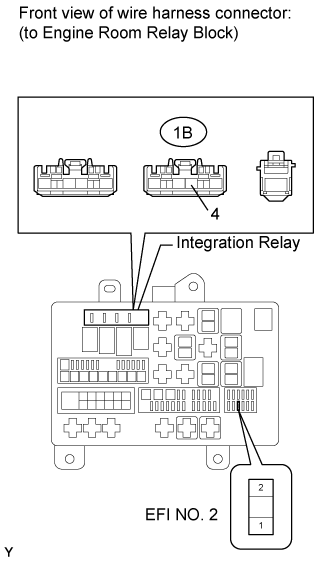

| 7.CHECK HARNESS AND CONNECTOR (ENGINE ROOM RELAY BLOCK) |

Remove the EFI NO. 2 fuse from the engine room relay block.

Remove the integration relay from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

| Tester Connection | Condition | Specified Condition |

| EFI NO. 2 fuse (1) - 1B-4 | Always | Below 1 Ω |

- Standard Resistance (Check for Short):

| Tester Connection | Condition | Specified Condition |

| EFI NO. 2 fuse (1) or 1B-4 - Body ground | Always | 10 kΩ or higher |

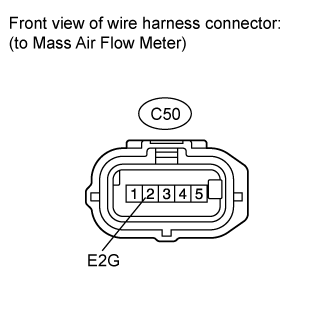

| 8.CHECK HARNESS AND CONNECTOR (SENSOR GROUND) |

Disconnect the mass air flow meter connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

| Tester Connection | Condition | Specified Condition |

| C50-2 (E2G) - Body ground | Always | Below 1 Ω |

| 9.CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM) |

Disconnect the mass air flow meter connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

for LHD| Tester Connection | Condition | Specified Condition |

| C50-3 (VG) - C45-72 (VG) | Always | Below 1 Ω |

| C50-2 (E2G) - C45-118 (EVG) | Always | Below 1 Ω |

for RHD| Tester Connection | Condition | Specified Condition |

| C50-3 (VG) - C46-72 (VG) | Always | Below 1 Ω |

| C50-2 (E2G) - C46-118 (EVG) | Always | Below 1 Ω |

- Standard Resistance (Check for Short):

for LHD| Tester Connection | Condition | Specified Condition |

| C50-3 (VG) or C45-72 (VG) - Body ground | Always | 10 kΩ or higher |

for RHD| Tester Connection | Condition | Specified Condition |

| C50-3 (VG) or C46-72 (VG) - Body ground | Always | 10 kΩ or higher |

| 11.REPLACE MASS AIR FLOW METER |

Replace the mass air flow meter ().

| 12.REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 13.CHECK FOR SHORTS IN ALL HARNESSES AND CONNECTORS CONNECTED TO FUSE AND REPLACE FUSE |

| 14.CHECK ECM POWER SOURCE CIRCUIT |

Check the ECM power source circuit ().

| 15.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the intelligent tester to the DLC3.

Turn the ignition switch off.

Turn the ignition switch to ON for 3 seconds

Enter the following menus: Powertrain / Engine / DTC.

Confirm that the DTC is not output again.