DTC P1386 Injector for Exhaust Fuel Addition

Description

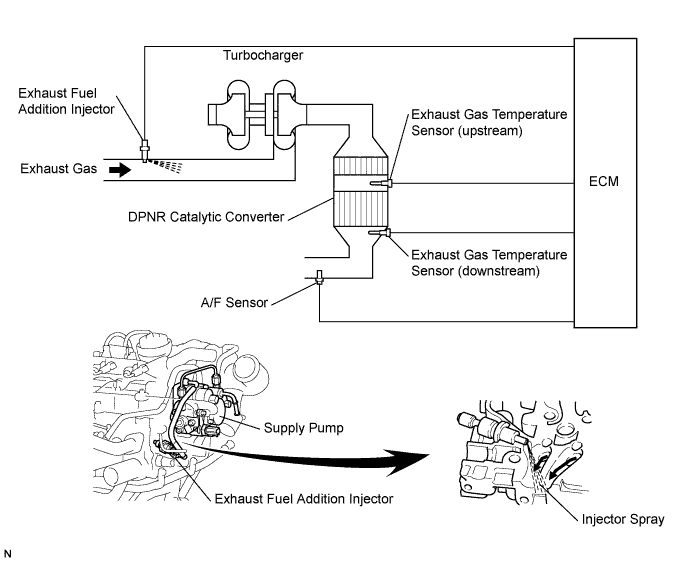

The exhaust fuel addition injector is mounted on the exhaust port of the cylinder head, and low pressure is provided to the injector by the feed pump in the supply pump. This injector adds fuel by a control signal from the ECM.

This injector is used for two different controls: DPNR catalyst regeneration and nitrogen oxide (NOx) reduction.

Under the DPNR catalyst regeneration control, the injector adds fuel to raise a catalyst temperature.

In the other control, the injector helps the air-fuel ratio become RICH. As a result, NOx in the exhaust gas will be reduced in response to the RICH air-fuel ratio.

HINT:

- For more information on the exhaust fuel addition injector and TOYOTA D-CAT*1, refer to the following procedures.

- If P1386 is present, refer to the diagnostic trouble code (DTC) chart for TOYOTA D-CAT.

- "Learning value" represents a correction learning value of the fuel addition volume to raise the DPNR*2 catalyst temperature to a target range.

*1: Diesel Clean Advanced Technology

*2: Diesel Particulate-NOx Reduction system

Toyota fault code list DTC P1386

| DTC No. | DTC Detection Condition | Main Trouble Area | Related Trouble Area |

| P1386 | Excess or low fuel addition volume from exhaust fuel addition injector: Air-fuel ratio deviates from a value estimated by ECM while the injector is adding fuel (1 trip detection logic) |

|

|

| Low fuel addition volume from exhaust fuel addition injector: Learning value*3 exceeds standard level (1 trip detection logic) |

|||

| Exhaust fuel addition injector nozzle stuck open: Air-fuel ratio becomes RICHER than standard level, or exhaust gas temperature becomes higher than standard level (1 trip detection logic) |

*3: Correction learning value of the fuel addition volume to raise the DPNR catalyst temperature to a target range.

HINT:

- DTC P2047, P2048 or P2049 will be present if there is an open malfunction in the exhaust fuel addition injector circuit.

- If any one of the main injectors has a closed valve malfunction, rough idle will result. Compensatory injection volume learning values of each cylinder can be read by using the intelligent tester. When the value is more than 3.0 mm3, the cylinder is malfunctioning.

- Usually compensation injection volume is 3.0 mm3 or less.

Monitor description

HINT:

"Learning value" represents a correction learning value of the fuel addition volume to raise the DPNR*4 catalyst temperature to a target range.

*4: Diesel Particulate-NOx Reduction system.

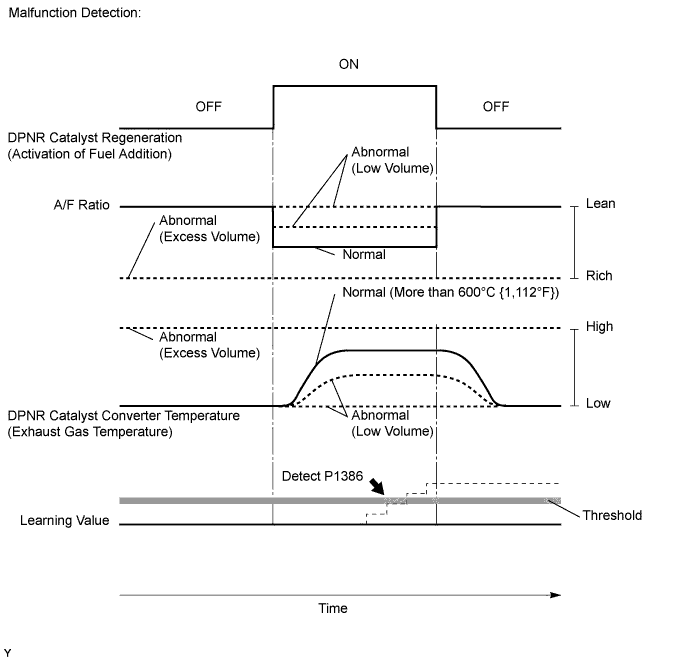

In order to detect malfunctions in the exhaust fuel addition injector, the ECM monitors the air-fuel ratio, DPNR catalytic temperature and learning value.

- When the exhaust fuel addition injector adds fuel during NOx reduction, the ECM monitors the air-fuel ratio when the exhaust fuel addition injector adds fuel. If the air-fuel ratio is too RICH or too LEAN against the ECM predetermined air-fuel ratio, the ECM determines that the fuel addition volume is small or large, and illuminates the MIL. For this malfunction, there is no fail-safe operation.

- The ECM always monitors the DPNR catalytic converter temperature and the air-fuel ratio. When the temperature becomes higher than its usual level or the air-fuel ratio becomes extremely RICH, the ECM judges that the injector is stuck open and illuminates the MIL. If this malfunction occurs, the ECM enters the fail-safe mode to limit the acceptable vehicle speed to approximately 80 km/h (50 mph) by limiting the engine power.

- During DPNR catalyst regeneration, the ECM monitors the learning value. Normally, the learning value for the DPNR catalyst regeneration is in the vicinity of 1.0. Thus if the learning value is at 1.99 or more for a certain period of time, the ECM judges the fuel addition volume from the injector is insufficient and illuminates the MIL. If this malfunction occurs, the ECM enters the fail-safe mode to limit the acceptable vehicle speed to approximately 80 km/h (50 mph) by limiting the engine power.

| Fail-Safe Operation | Malfunction Condition | Malfunction Detection Condition | Drive Pattern |

| No fail-safe operation | Low or excess fuel addition volume from the exhaust fuel addition injector | When the exhaust fuel addition injector adds fuel during NOx reduction, if actual air-fuel ratio deviates from a value estimated by the ECM when the exhaust fuel addition injector adds fuel | After warming up the engine perform DPNR REJU (PM) in the ACTIVE TEST menu using the intelligent tester, and drive at constant vehicle speed within 50 to 100 km/h (31 to 62 mph) for more than 15 minutes |

| Limits engine power to maximum vehicle speed of approximately 80 km/h (50 mph) | Exhaust fuel addition injector is stuck open | DPNR catalytic converter temperature becomes higher than 800°C (1,472°F) or air-fuel ratio is less than approximately 12,0: 1 for a couple of seconds | Idling engine for more than 5 minutes*5 |

| Limits engine power to maximum vehicle speed of approximately 80 km/h (50 mph)

HINT: DPNR catalyst regeneration is prohibited

|

Low fuel addition volume from the exhaust fuel addition injector | During DPNR catalyst regeneration, when learning value of 1.99 or more continues for a certain period of time*6 | After warming up the engine perform DPNR REJU (PM) in the ACTIVE TEST menu using the intelligent tester, and drive at constant vehicle speed within 50 to 100 km/h (31 to 62 mph) for more than 30 minutes |

*5: The DPNR catalytic converter temperature will not reach 800°C (1,472°F) or higher during idle even if the exhaust fuel addition injector is stuck open.

*6: While the DPNR catalyst regeneration is performed, the ECM raises the DPNR catalytic converter temperature to more than 600°C (1,112°F) by adding fuel using the exhaust fuel addition injector. If the temperature does not reach 600 °C (1,112 °F) during the attempt, the correction learning value of the fuel addition volume increases by increments in order to raise the DPNR catalytic converter temperature to the target range.

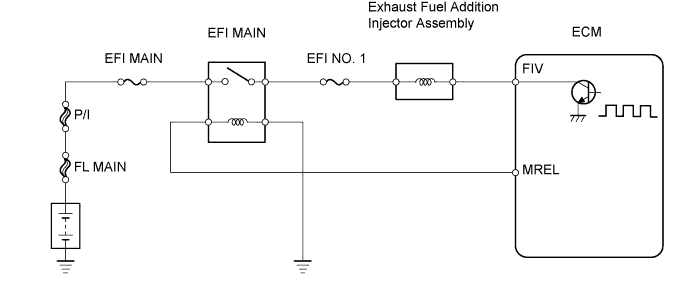

Wiring diagram

Inspection procedure

HINT:

"Learning value" used in here represents a correction learning value of the fuel addition volume to raise the DPNR catalyst temperature to a target range.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG) and turn the tester ON.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read DTCs.

Result:Display (DTC Output) Proceed to P1386 A P1386 and other DTCs B HINT:

If codes other than P1386 are output, perform troubleshooting for those DTCs first.

|

|

||||

| A | |

-

Check the condition of fail-safe operation while the MIL is being illuminated.

Result:Condition of Fail-Safe Operation Proceed to Limits vehicle speed to approximately 80 km/h (50 mph) A No fail-safe operation B

|

|

||||

| A | |

| 3.READ VALUE OF EXHAUST GAS TEMPERATURE SENSOR |

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG) and turn the tester ON. (Do not start the engine.)

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Initial Exhaust Temp (In) and Initial Exhaust Temp (Out).

-

Read the value.

Result:Temperature Displayed Proceed to OK (Same value as actual exhaust gas temperature) A 1,000°C (1,832°F) B HINT:

If there is an open circuit, the tester indicates 1,000°C (1,832°F).

|

|

||||

| A | |

| 4.PERFORM ENGINE RPM ACCELERATION (WHITE SMOKE AND FUEL ODOR) |

CAUTION:

Stop the engine immediately if there is white smoke or fuel odors during the below inspection. Fuel may be leaking from the exhaust fuel addition injector.

-

Remove the cable from the negative (-) battery terminal for 1 minute, and then reconnect the cable.

-

After the engine starts, promptly accelerate the engine to approximately 3,000 rpm with no load 3 times.

-

Check for white smoke in exhaust gases.

-

Check for fuel odors in exhaust gases.

Result:Result Proceed to Either white smoke or fuel odors in exhaust gases A Other than above B

|

|

||||

| B | |

| 5.READ VALUE OF A/F RATIO |

CAUTION:

Stop the engine immediately if there is white smoke or fuel odors during the below inspection. Fuel may be leaking from the exhaust fuel addition injector.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG) and turn the tester ON.

-

Start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Data List.

-

Read the air-fuel ratio displayed on the tester after idling the engine for 3 minutes.

Result:A/F Ratio Proceed to More than 12 A Less than 12 B

|

|

||||

| A | |

| 6.READ VALUE OF EXHAUST GAS TEMPERATURE SENSOR |

CAUTION:

Stop the engine immediately if there is white smoke or fuel odors during the below inspection. Fuel may be leaking from the exhaust fuel addition injector.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG) and turn the tester ON.

-

Start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Initial Exhaust Temp (In) and Initial Exhaust Temp (Out).

-

Check that the exhaust gas temperature is within the specification below.

OK:

Condition Exhaust Gas Temperature Idling after warming up engine Constant at approximately 50 to 700°C (122 to 1,292°F)

|

|

||||

| OK | |

| 7.READ VALUE OF A/F RATIO |

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG) and turn the tester ON.

-

Start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Data List.

-

After warming up the engine, check if the air-fuel ratio varies when accelerating the engine from idling to 3,000 rpm by fully depressing the accelerator pedal 3 times.

Result:Air-fuel Ratio Proceed to Varies OK Not varies once NG

|

|

||||

| OK | |

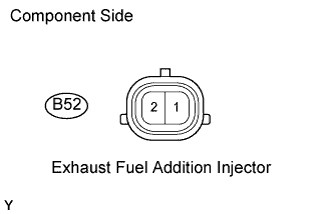

| 8.INSPECT EXHAUST FUEL ADDITION INJECTOR |

-

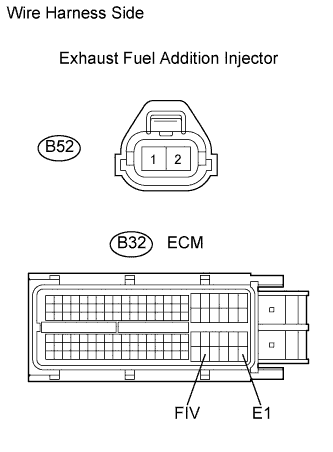

Disconnect the B52 exhaust fuel addition injector connector.

-

Measure the resistance of the terminals of the exhaust fuel addition injector.

Standard resistance:

Tester Connection Condition Specified Condition B52-1 - B52-2 20°C (68°F) 6.8 to 8.2 ? -

Reconnect the exhaust fuel addition injector connector.

|

|

||||

| OK | |

| 9.CHECK WIRE HARNESS (EXHAUST FUEL ADDITION INJECTOR - ECM) |

-

Disconnect the B52 exhaust fuel addition injector connector.

-

Disconnect the B32 ECM connector.

-

Measure the resistance of the wire harness side connectors.

Standard resistance:

Tester Connection Specified Condition B52-1 - B32-105 (FIV) Below 1 ? B52-2 - B32-109 (E1) Below 1 ? B52-1 or B32-105 (FIV) - Body ground 10 k? or higher -

Reconnect the exhaust fuel addition injector connector.

-

Reconnect the ECM connector.

|

|

||||

| OK | |

| 10.CHECK FOR FUEL LEAKAGE (IN EXHAUST FUEL ADDITION INJECTOR) |

-

Visually check if there is a fuel leak between the supply pump and exhaust fuel addition injector.

HINT:

- Primary pressure of a maximum of 1 MPa (10 kgf/cm2, 145 psi) is provided from a feed pump inside the supply pump to the exhaust fuel addition injector.

- Fuel leaks are possible inside the components (supply pump, etc.).

|

|

||||

| OK | |

| 11.READ VALUE OF INJECTION VOLUME (COMPENSATION OF INJECTION VOLUME) |

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG) and turn the tester ON.

-

Start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Injection Feedback Value.

-

Read the value.

Result:Result Proceed to Compensatory injection volume is more than 3.0 mm3 A Compensatory injection volume is 3.0 mm3 or less B HINT:

Usually compensation injection volume is 3.0 mm3 or less.

|

|

||||

| A | |

| 12.CHECK ENGINE COMPONENT PARTS |

-

Check that there is no abnormality in the main injector, cylinder compression pressure, valve timing, and valve clearance.

-

Check that there is no leakage or blockage in the air intake, exhaust, and EGR systems.

|

|

||||

| OK | |

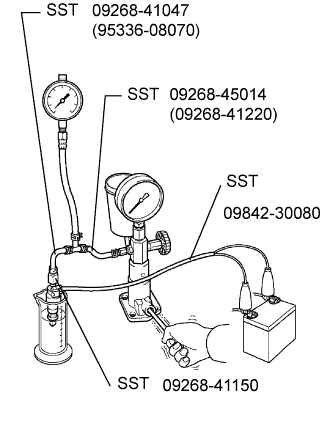

| 13.INSPECT EXHAUST FUEL ADDITION INJECTOR (INJECTION VOLUME) |

-

Remove the exhaust fuel addition injector.

-

Using SST, attach the exhaust fuel addition injector to a nozzle tester.

Специальный инструмент (SST):

09268-41047 (95336-08070)

09268-45014 (09268-41220)

09268-41150

-

Apply a pressure of 0.29 MPa (3.0 kgf/cm2, 42 psi) to the nozzle tester.

-

Connect SST (wire) to the exhaust fuel addition injector.

Специальный инструмент (SST):

09842-30080

-

Inspect the injector.

OK:

Condition Result Leave the injector undisturbed for 1 minute with fuel pressurized No leakage from the injector Apply battery voltage to the injector Fuel is emitted from the injector HINT:

- Injection volume after leaving the exhaust fuel addition injector for 10 seconds with the pressurized fuel applied is as follows:

Reference:

25 cm3 (1.5 cu.in.)

- The above is a reference value. Your reading may differ from this value depending on the measuring conditions, etc.

- Check that the nozzle of the exhaust fuel addition injector is not clogged.

- Injection volume after leaving the exhaust fuel addition injector for 10 seconds with the pressurized fuel applied is as follows:

-

Reinstall the exhaust fuel addition injector.

|

|

||||

| OK | |

| 14.PERFORM ACTIVE TEST BY INTELLIGENT TESTER (DPNR CATALYST REGENERATION) |

-

Clear the learning value by removing the cable from the negative (-) battery terminal for more than 1 minute.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG) and turn the tester ON.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the DPNR Rejuvenate (PM).

-

After warming up the engine, drive the vehicle at a constant speed within 50 to 100 km/h (31 to 62 mph) (with smooth throttle operations) for more than 15 minutes.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / AFS FT B1 S1, Initial Exhaust Temp (In), Initial Exhaust Temp (Out) and Exhaust Fuel Addition FB.

-

Check the exhaust gas temperatures (Initial Exhaust Temp (In) and (Out)) and the learning value (Exhaust Fuel Addition FB).

Result:Result Proceed to Exhaust gas temperature does not become higher than 600°C (1,112°F) A Exhaust gas temperature becomes higher than 600°C (1,112°F), and the learning value remains in the vicinity of 1.0 B

|

|

||||

| A | |

| 15.REPLACE EXHAUST FUEL ADDITION INJECTOR |

-

Replace the exhaust fuel addition injector.

| NEXT | |

| 16.PERFORM ACTIVE TEST BY INTELLIGENT TESTER (DPNR CATALYST REGENERATION) |

-

Clear the learning value by removing the cable from the negative (-) battery terminal for more than 1 minute.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG) and turn the tester ON.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the DPNR Rejuvenate (PM).

-

After warming up the engine, drive the vehicle at a constant speed within 50 to 100 km/h (31 to 62 mph) (with smooth throttle operations) for more than 15 minutes.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / AFS FT B1 S1, Initial Exhaust Temp (In), Initial Exhaust Temp (Out) and Exhaust Fuel Addition FB.

-

Check the exhaust gas temperatures (Initial Exhaust Temp (In) and (Out)) and the learning value (Exhaust Fuel Addition FB).

Result:Result Proceed to Exhaust gas temperature does not become higher than 600°C (1,112°F) A Exhaust gas temperature becomes higher than 600°C (1,112°F), and the learning value remains in the vicinity of 1.0 B

|

|

||||

| A | |

|

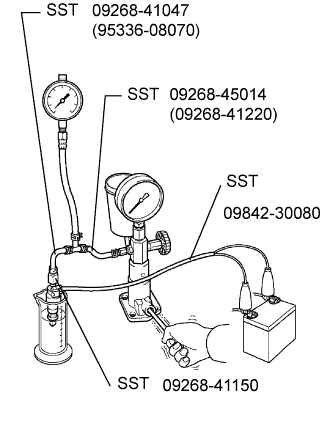

| 17.INSPECT EXHAUST FUEL ADDITION INJECTOR (INJECTION VOLUME) |

-

Remove the exhaust fuel addition injector.

-

Using SST, attach the exhaust fuel addition injector to a nozzle tester.

Специальный инструмент (SST):

09268-41047 (95336-08070)

09268-45014 (09268-41220)

09268-41150

-

Apply a pressure of 0.29 MPa (3.0 kgf/cm2, 42 psi) to the nozzle tester.

-

Connect SST (wire) to the exhaust fuel addition injector.

Специальный инструмент (SST):

09842-30080

-

Inspect the injector.

OK:

Condition Result Leave the injector undisturbed for 1 minute with fuel pressurized No leakage from the injector Apply battery voltage to the injector Fuel is emitted from the injector HINT:

- Injection volume after leaving the exhaust fuel addition injector for 10 seconds with the pressurized fuel applied as follows:

Reference:

25 cm3 (1.5 cu.in.)

- The above is a reference value. Your reading may differ from this value depending on the measuring conditions, etc.

- Check that the nozzle of the exhaust fuel addition injector is not clogged.

- Injection volume after leaving the exhaust fuel addition injector for 10 seconds with the pressurized fuel applied as follows:

-

Reinstall the exhaust fuel addition injector.

|

|

||||

| OK | |

|