DTC P1238 Injector Malfunction

P1238 Description

HINT:

- For more information on the injector and the common rail system, refer to the following procedures .

- After clearing the DTC, let the engine idle for 10 minutes after warm-up, and then confirm that P1238 is not present again.

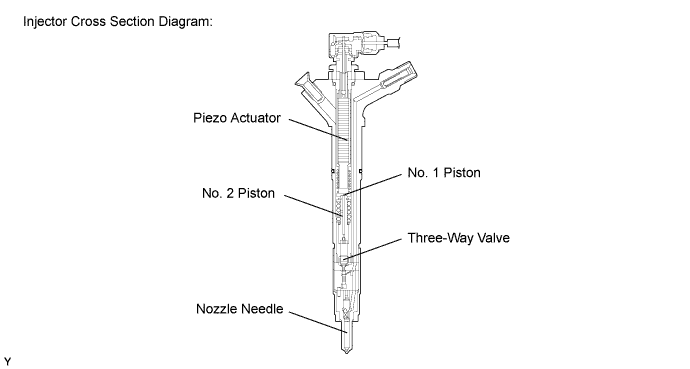

The actuator in the injector, which operates the nozzle needle, is a piezo type to allow high-speed operation. This high speed injector allows a two stage injection to reduce combustion noise, and allow high power output.

An injector consists of a nozzle needle, two pistons, three-way valve and a piezo actuator.

An injector compensation value and Quick Response (QR) code containing encoded characteristics of the individual injector are printed on each injector.

The injector compensation value and QR code contain various information regarding the injector, such as model code, and injection volume correction.

The ECM detects combustion deterioration for each specific cylinder.

HINT:

- A cylinder which has an injection volume compensation value that varies from other cylinders may be malfunctioning.

- If DTC P0093 (Fuel leaks in high-pressure area) is present simultaneously, a leakage malfunction of the injector for the affected cylinder probably has occurred.

- If DTC P0200 (Open or short in EDU or injector circuit) is present simultaneously, there probably is a fault in the circuit between the ECM and the injector. This fault may also be as a result of the EDU.

- If only DTC P1238 (Injector malfunction) is present, the probable cause is an injector mechanical malfunction or insufficient compression (valve, etc.), not an open or short malfunction of the ECM, EDU and injector circuit.

- The solenoid valve of the injector is the same type as that of the pressure discharge valve.

Toyota fault code listDTC P1238

| DTC No. | DTC Detection Condition | Main Trouble Area | Related Trouble Area |

| P1238 | Engine speed fluctuation is large when idling (2 trip detection logic) |

|

|

HINT:

After confirming DTC P1238, check the internal fuel pressure in "Powertrain / Engine and ECT / Data List / Fuel Press" menu using the intelligent tester.

Reference:

| Engine Speed | Fuel Pressure (MPa) |

| Idling | Approximately 37 to 43 |

| 2,500 rpm (No engine load) | Approximately 57 to 63 |

P1238 Monitor description

- P1238 (Injection malfunction, except open or short in injector circuit):

This DTC will be set if the engine speed fluctuation between each cylinder is large. The ECM monitors changes in the crankshaft rotation speed using the crankshaft position sensor in order to detect improper combustion. The camshaft position sensor also plays a role in determining which cylinder has the problem. The fluctuation counter increments when irregular crankshaft rotation speed variation exceeds the threshold with the engine idling. Therefore, if any one of the cylinders is operating poorly (rough idle), the ECM sets this DTC.

P1238 Monitor strategy

| Required Sensors | Crankshaft position sensor |

| Frequency of operation | Continuous |

| Duration | 10 minutes |

| MIL Operation | 2 driving cycles |

Typical enabling conditions

| Item | Specification | |

| Minimum | Maximum | |

| Engine | At idling | |

| Engine speed | 700 rpm | - |

| Engine coolant temperature | 20°C (68°F) | - |

Typical malfunction thresholds

| Threshold |

| The number of irregular changes in the crankshaft rotation speed |

HINT:

The number of irregular changes in the crankshaft rotation speed indicates the insufficient combustion.

Inspection procedure

NOTICE:

After replacing an injector, the ECM needs registration.

HINT:

If DTCs other than P1238 are present simultaneously, first perform troubleshoot those DTCs.

| 1.CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P1238) |

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG) and turn the tester ON.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read DTCs.

Result:Display (DTC Output) Proceed to P1238 A P1238 and other DTCs B HINT:

If any other codes besides P1238 are output, perform troubleshooting for those DTCs first.

|

|

||||

| A | |

| 2.CHECK WIRE HARNESS (ENGINE WIRE HARNESS) |

HINT:

Check the wire harness and connector connections.

|

|

||||

| OK | |

| 3.READ VALUE OF INJECTION VOLUME (COMPENSATION OF INJECTION VOLUME BETWEEN CYLINDERS) |

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG) and turn the tester ON.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Injection Feedback #1, #2, #3, and #4.

-

Read the value.

Standard value:

Item Standard Value Compensatory Injection Volume 4.9 (mm3) or less HINT:

A typical injection compensation value is 3.0 mm3or less.

-

Cylinders that have a compensation value which is more than the value specified above are considered to be faulty. Use the following steps to inspect and repair the cylinder.

Result:Result Proceed to Faulty cylinder is not identified A Faulty cylinder is identified B

|

|

||||

| A | |

| 4.PERFORM ACTIVE TEST BY INTELLIGENT TESTER (INJECTION CUT FOR IDENTIFYING MALFUNCTIONING CYLINDER) |

-

Connect the intelligent tester to the DLC3.

-

Start the engine.

-

Turn the tester ON.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Cylinder #1 (to #4) Fuel Cut.

-

Check the four cylinders in sequence to identify a faulty cylinder by performing the power balance inspection.

HINT:

If the engine idle does not change when an injector is disabled, the cylinder being tested is malfunctioning.

| NEXT | |

| 5.CHECK CYLINDER COMPRESSION PRESSURE OF MALFUNCTIONING CYLINDER |

-

Check the cylinder compression pressure.

Standard pressure:

2,700 kPa (27.5 kgf/cm2, 392 psi)

Minimum pressure:

2,200 kPa (22.4 kgf/cm2, 319 psi)

Difference between each cylinder:

500 kPa (5.1 kgf/cm2, 73 psi)

|

|

||||

| OK | |

| 6.CHECK IF DTC OUTPUT RECURS (DTC P1238) |

HINT:

After clearing the DTC, let the engine idle for 10 minutes after warm-up, and then confirm that P1238 is not present again.

|

|

||||

| NG | |

| 7.REPLACE INJECTOR ASSEMBLY |

| NEXT | |

|