Система Смазки -- Проверка Без Снятия С Автомобиля |

| 1. CHECK ENGINE OIL LEVEL |

Warm up the engine. Then stop the engine and wait for 5 minutes.

Check that the engine oil level is between the 2 marks on the oil level gauge.

If low, check for leakage and top up oil to the upper mark.- ПРИМЕЧАНИЕ:

- Do not add engine oil to above the upper mark.

| 2. CHECK ENGINE OIL QUALITY |

Check the engine oil for deterioration, water intrusion, discoloration and thinning.

If the oil quality is visibly poor, replace the oil.

| 3. INSPECT OIL PRESSURE |

Remove the engine under cover.

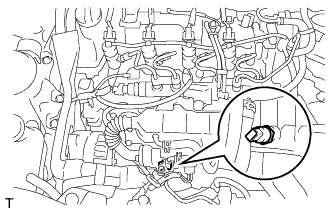

Disconnect the oil pressure switch connector.

Using a 22 or 24 mm deep socket wrench, remove the oil pressure switch.

- УКАЗАНИЕ:

- As there are 2 kinds of oil pressure switches, select and use either a 22 or 24 mm deep socket wrench as appropriate.

|

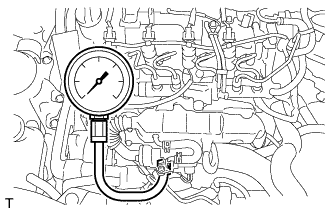

Install the oil pressure gauge.

|

Warm up the engine.

Check the oil pressure.

- Oil pressure:

Engine rpm Oil pressure 770 rpm 29 kPa (0.3 kgf*cm2, 4.3 psi) or more 3000 rpm 150 to 550 kPa (1.5 to 5.6 kgf*cm2, 22 to 80 psi)

Remove the oil pressure gauge.

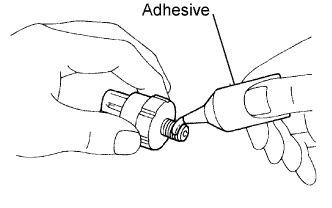

Apply adhesive to 2 or 3 threads of the oil pressure switch.

- Adhesive:

- TOYOTA Genuine Adhesive 1344, Three Bond 1344 or equivalent

|

Using a 22 or 24 mm deep socket wrench, install the oil pressure switch.

- Момент затяжки:

- 15 Н*м{153 кгс*см, 11 фунт-сила-футов}

- ПРИМЕЧАНИЕ:

- Do not start the engine for at least 1 hour after installation.

Connect the oil pressure switch connector.

Check for engine oil leakage.

Install the engine under cover.

| 4. INSPECT ENGINE OIL LEVEL SENSOR |

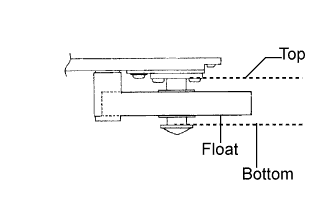

Remove the engine oil level sensor.

|

Measure the resistance according to the value(s) in the table below.

Standard resistance Tester Connection Condition Specified Condition 1 - 2 Float position is at the top Below 1 Ω 1 - 2 Float position is at the bottom 10 kΩ or higher