Топливная Форсунка -- Установка |

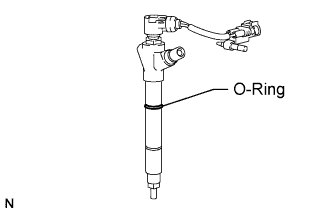

| 1. INSTALL INJECTOR ASSEMBLY |

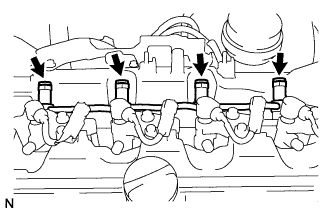

Install 4 new nozzle seats to the cylinder head.

Install new O-rings to each injector.

|

Apply a light coat of engine oil to the O-rings on each injector.

Install the 4 injectors to the cylinder head.

- ПРИМЕЧАНИЕ:

- Fit the injectors to the nozzle seats.

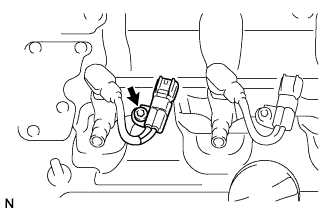

Temporarily install the 4 clamps to the cylinder head with the 4 bolts.

|

Using a hexagon socket wrench, tighten the 4 bolts.

- Момент затяжки:

- 9 Н*м{92 кгс*см, 80 фунт-сила-дюймов}

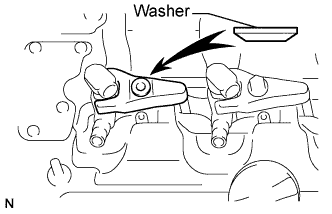

Install the nozzle holder clamps and washers as shown in the illustration.

|

Temporarily install the nozzle holder clamp bolts.

- ПРИМЕЧАНИЕ:

- Pay attention to the mounting orientation (bevelled edge) of the washer.

- When temporarily attaching the nozzle holder clamp and the nozzle holder clamp bolt, be careful not to position them at an angle.

- УКАЗАНИЕ:

- Apply a light coat of engine oil to the threads of the nozzle holder clamp bolts.

Temporarily install the No. 1, No. 2, No. 3 and No. 4 injection pipes.

Temporarily install 4 new gaskets and the No. 1 nozzle leakage pipe assembly with the 4 union bolts.

Tighten the 4 nozzle holder clamp bolts.

- Момент затяжки:

- 25 Н*м{255 кгс*см, 18 фунт-сила-футов}

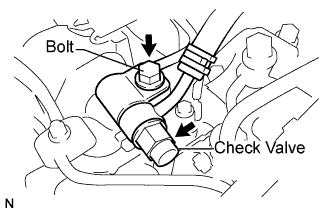

| 2. INSTALL NO. 1 NOZZLE LEAKAGE PIPE ASSEMBLY |

Temporarily install a new gasket, the fuel check valve and bolt.

|

Tighten the 4 union bolts.

- Момент затяжки:

- 18 Н*м{184 кгс*см, 13 фунт-сила-футов}

|

Tighten the fuel check valve and bolt.

- Момент затяжки:

- For fuel check valve:

- 32 Н*м{321 кгс*см, 23 фунт-сила-футов}

- For bolt:

- 21 Н*м{209 кгс*см, 15 фунт-сила-футов}

| 3. INSTALL NO. 1 INJECTION PIPE SUB-ASSEMBLY |

- ПРИМЕЧАНИЕ:

- In a case where an injector is replaced, the injection pipes must also be replaced.

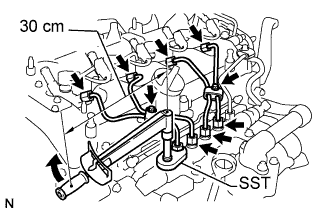

Temporarily install the 4 injection pipes.

|

Using SST, first tighten the nut at the common rail end of the injection pipe.

- SST

- 09023-38401

- Момент затяжки:

- With SST:

- 27 Н*м{275 кгс*см, 20 фунт-сила-футов}

- Момент затяжки:

- Without SST:

- 30 Н*м{306 кгс*см, 22 фунт-сила-футов}

- УКАЗАНИЕ:

- Use of proper SST is required to ensure that the correct torque is applied to the injection pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation.

If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new one.

Using SST, tighten the nut at the injector end of the injection pipe.

- SST

- 09023-38401

- Момент затяжки:

- With SST:

- 27 Н*м{275 кгс*см, 20 фунт-сила-футов}

- Момент затяжки:

- Without SST:

- 30 Н*м{306 кгс*см, 22 фунт-сила-футов}

- УКАЗАНИЕ:

- Use of proper SST is required to ensure that the correct torque is applied to the injection pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation.

If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new one.

| 4. INSTALL NO. 2 INJECTION PIPE SUB-ASSEMBLY |

- УКАЗАНИЕ:

- Perform the same procedure as for the No. 1 injection pipe.

| 5. INSTALL NO. 3 INJECTION PIPE SUB-ASSEMBLY |

- УКАЗАНИЕ:

- Perform the same procedure as for the No. 1 injection pipe.

| 6. INSTALL NO. 4 INJECTION PIPE SUB-ASSEMBLY |

- УКАЗАНИЕ:

- Perform the same procedure as for the No. 1 injection pipe.

Install the 4 injection pipe clamps with the 2 bolts.

- Момент затяжки:

- 5.0 Н*м{51 кгс*см, 44 фунт-сила-дюймов}

| 7. CONNECT ENGINE WIRE |

Connect the engine wire to the engine cover bracket.

|

Connect the glow plug harness.

Install the 2 nuts (*1).

Install the nut and grommet (*2).

- Момент затяжки:

- 2.2 Н*м{22 кгс*см, 19 фунт-сила-дюймов}

Connect the turbo pressure sensor connector (*3).

Connect the discharge valve connector (*4).

Connect the fuel pressure sensor connector (*5).

| 8. INSTALL NO. 1 ENGINE COVER |

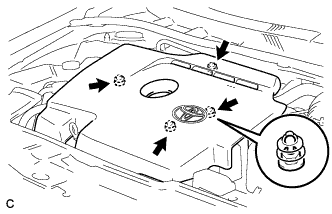

Attach the 4 clips to install the engine cover.

- ПРИМЕЧАНИЕ:

- Line up the 4 grommets using the oil filler cap and oil dipstick as guides.

- Push down on the four locations shown to install the cover.

|

| 9. REGISTRATION OF INJECTOR COMPENSATION CODE |

- УКАЗАНИЕ:

- Each injector assembly has a characteristic fuel injecting behavior (See page Нажмите здесь).

| 10. INSPECT FOR FUEL LEAK |

PERFORM ACTIVE TEST

Connect the intelligent tester to the DLC3.

Turn the ignition switch to the ON position.

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine / Active Test.

Perform the Active Test.

Tester Display Test Part Control Range Diagnostic Notes Test the Fuel Leak Pressurizing common rail internal fuel pressure, and checking for fuel leaks. Stop/Start - Fuel pressure inside common rail is pressurized to specified value and engine speed is increased to 2000 rpm when ON is selected.

- Above conditions are maintained while test is ON.

- Fuel pressure inside common rail is pressurized to specified value and engine speed is increased to 2000 rpm when ON is selected.