CHECK ANY OTHER DTC OUTPUT (IN ADDITION TO MISFIRE DTCS)

READ VALUE OF INTELLIGENT TESTER (MISFIRE RPM AND MISFIRE LOAD)

CHECK PCV HOSE (HOSE CONNECTION)

CHECK MISFIRE COUNT (CYL #1, #2, #3, #4, #5 AND #6)

CHECK CYLINDER COMPRESSION PRESSURE (MISFIRING CYLINDER)

CHANGE NORMAL SPARK PLUG AND CHECK SPARK OF MISFIRING CYLINDER

CHECK FUEL PRESSURE (LOW PRESSURE SIDE)

CHECK FUEL PRESSURE (HIGH PRESSURE SIDE)

READ VALUE OF INTELLIGENT TESTER (COOLANT TEMP)

READ VALUE OF INTELLIGENT TESTER (MAF)

DTC P0300 Random / Multiple Cylinder Misfire Detected

DTC P0301 Cylinder 1 Misfire Detected

DTC P0302 Cylinder 2 Misfire Detected

DTC P0303 Cylinder 3 Misfire Detected

DTC P0304 Cylinder 4 Misfire Detected

DTC P0305 Cylinder 5 Misfire Detected

DTC P0306 Cylinder 6 Misfire Detected

Description

When the engine misfires, high concentrations of hydrocarbons (HC) enter the exhaust gas. Extremely high HC concentration levels can cause increase in exhaust emission levels. High concentrations of HC can also cause increases in the Three-Way Catalytic Converter (TWC) temperature, which may cause damage to the TWC. To prevent this increase in emissions and to limit the possibility of thermal damage, the ECM monitors the misfire rate. When the temperature of the TWC reaches the point of thermal degradation, the ECM blinks the MIL. To monitor misfires, the ECM uses both the Camshaft Position (CMP) sensor and the Crankshaft Position (CKP) sensor. The CMP sensor is used to identify any misfiring cylinders and the CKP sensor is used to measure variations in the crankshaft rotation speed. Misfires are counted when the crankshaft rotation speed variations exceed predetermined thresholds. If the misfire exceeds the threshold levels, and could cause emission deterioration, the ECM illuminates the MIL and set a DTC.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0300 | Simultaneous misfiring of several cylinder detected (2 trip detection logic) |

|

| P0301 P0302 P0303 P0304 P0305 P0306 |

Misfiring of specific cylinder detected (2 trip detection logic) |

|

When DTCs for misfiring cylinders are randomly set, but DTC P0300 is not set, it indicates that misfires have been detected in different cylinders at different times. DTC P0300 is only set when several misfiring cylinders are detected at the same time.

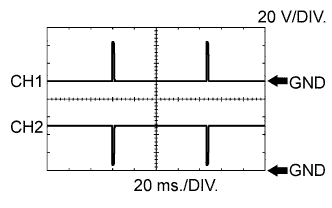

Reference: Inspection using an oscilloscope.

HINT:

- The correct waveform is as shown.

- With the engine idling, check the waveform between terminals #10 to #60 and E1 of the ECM connectors.

| Item | Content |

| Terminals | CH 1: #10 to #60 - E1 CH 2: INJF - E1 |

| Equipment Settings | 20 V/DIV. 20 ms./DIV. |

| Conditions | Idling |

Wiring diagram

Refer to DTC P0200 . Refer to DTC P0351 .

CONFIRMATION DRIVING PATTERN

- Connect the intelligent tester to the DLC3.

- Turn the engine switch on (IG).

- Turn the tester ON.

- Record the DTC(s) and freeze frame data.

- Using the tester, switch the ECM from normal mode to check mode .

- Read the misfire counts of each cylinder (CYL #10 to #60 with the engine in an idling condition. If any misfire count is displayed, skip the following confirmation driving pattern.

- Drive the vehicle several times with the conditions, such as engine rpm and engine load, shown in Misfire RPM and Misfire Load in the Data List.

HINT:

In order to store misfire DTCs, it is necessary to drive the vehicle for the period of time shown in the table below, with the Misfire RPM and Misfire Load in the Data List.

Engine RPM Duration Idling 3.5 minutes or more 1,000 3 minutes or more 2,000 1.5 minutes or more 3,000 1 minute or more - Check whether misfires have occurred by checking DTCs and freeze frame data.

HINT:

Do not turn the engine switch off until the stored DTC(s) and freeze data have been recorded. When the ECM returns to normal mode (default), the stored DTC(s), freeze frame data and other data will be erased.

- Record the DTC(s), freeze frame data and misfire counts.

- Turn the engine switch OFF and wait for at least 5 seconds.

Inspection procedure

HINT:

- If any DTCs other than misfire DTCs are output, troubleshoot those DTCs first.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when malfunctions are detected. When trouble shooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred .

- If the misfire does not recur when the vehicle is brought to the workshop, reproduce the conditions stored in the freeze frame data.

- The misfire still cannot be reproduced even though the conditions stored in the freeze frame data have been duplicated, one of the following factors is considered to be a possible cause of the problem:

- The fuel tank is low full.

- Improper fuel is used.

- The spark plugs have been contaminated.

- The problem is complex.

- After finishing repairs, check the misfire counts of the cylinders (Cylinder #1 (and #6) Misfire Rate).

- Be sure to confirm that no misfiring cylinder DTCs are set again by conducting the confirmation driving pattern, after repairs.

- For 6 and 8 cylinder engines, the ECM intentionally does not set the specific misfiring cylinder DTCs at high engine RPM. If misfires occur only in high engine RPM areas, only DTC P0300 is set.

In the event of DTC P0300 being present, perform the following operations:- Clear the DTC .

- Start the engine and conduct the confirmation driving pattern.

- Read the misfiring rates of each cylinder or DTC(s) using the tester.

- Repair the cylinder(s) that has a high misfiring rate or is indicated by the DTC.

- After finishing repairs, conduct the confirmation driving pattern again, in order to verify that DTC P0300 is not set.

- When one of Short FT #1, Long FT #1, Short FT #2 or Long FT #2 in the freeze frame data is outside the range of +-20 %, the air-fuel ratio may be RICH (-20 % or less) or LEAN (+20 % or more).

- When the COOLANT TEMP in the freeze frame data is less than 75°C (167°F), the misfire have occurred only while warming up the engine.

| 1.CHECK ANY OTHER DTC OUTPUT (IN ADDITION TO MISFIRE DTCS) |

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the tester ON.

-

Enter the following menus: Power train / Engine / DTC.

-

Read DTCs.

Result:

Display (DTC output) Proceed to P0300, P0301, P0302, P0303, P0304, P0305 and/or P0306 A P0300, P0301, P0302, P0303, P0304, P0305 and/or P0306 and other DTCs B HINT:

If any DTCs other than P0300, P0301, P0302, P0303, P0304, P0305 and P0306 are output, troubleshoot those DTCs first.

|

|

||||

| A | |

| 2.READ VALUE OF INTELLIGENT TESTER (MISFIRE RPM AND MISFIRE LOAD) |

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG) and turn the tester ON.

-

Enter the following menus: Power train / Engine / Data List / Misfire RPM and Misfire Load.

-

Read and note the MISFIRE RPM and MISFIRE LOAD (engine load) values.

HINT:

The Misfire RPM and Misfire Load indicate the vehicle conditions under which the misfire occurred.

| NEXT | |

| 3.CHECK PCV HOSE (HOSE CONNECTION) |

OK:

PCV hose is connected correctly and is not damaged.

|

|

||||

| OK | |

| 4.CHECK MISFIRE COUNT (CYL #1, #2, #3, #4, #5 AND #6) |

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the tester ON.

-

Clear DTCs.

-

Enter the following menus: Power train / Engine / Data List / Cylinder #1 (and #6) Misfire Rate (Procedure "A").

-

Allow the engine to idle.

-

Read each value of Cylinder #1 (to #6) Misfire Rate displayed on the tester. If no misfire counts occur in any cylinders, perform the following conditions: (Procedure "B").

-

Shift the gear selector lever to the D position.

-

Repeat procedure A to B above.

-

Check the Cylinder #1 (to #6) Misfire Rate.

-

If misfire counts are still not displayed, perform procedure C and D and then check the misfire counts again.

-

-

Drive the vehicle with Misfire RPM and Misfire Load noted in step 2 (Procedure "C").

-

Read the Cylinder #1 (to #6) Misfire Rate or DTCs displayed on the tester (Procedure "D").

Result:

Misfire count Proceed to 1 or 2 cylinders have misfire counts A 3 cylinders or more have misfire counts B

|

|

||||

| A | |

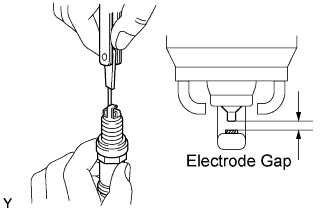

| 5.CHECK SPARK PLUG |

-

Remove the ignition coil and the spark plug of the misfiring cylinder.

-

Measure the spark plug electrode gap.

Standard:

Between 1.0 mm and 1.1 mm (0.039 in. and 0.043 in.)

-

Check the electrode for carbon deposits.

Recommended spark plug: Manufacture Product DENSO FK20HBR11 NGK ILFR6D11T NOTICE:

If the electrode gap is larger than standard, replace the spark plug. Do not adjust the electrode gap.

|

|

||||

| OK | |

| 6.CHECK FOR SPARKS AND IGNITION |

-

Disconnect the injector connectors, in order to prevent the engine from starting.

-

Install the spark plug to the ignition coil.

-

Attach the spark plug assembly to the cylinder head cover.

-

Crank the engine for less than 2 seconds and check the spark.

OK:

Sparks jump across electrode gap.

-

Reconnect the injector connectors.

|

|

||||

| OK | |

| 7.CHECK CYLINDER COMPRESSION PRESSURE (MISFIRING CYLINDER) |

-

Measure the cylinder compression pressure of the misfiring cylinder.

|

|

||||

| NG | ||

|

||

| 8.CHANGE NORMAL SPARK PLUG AND CHECK SPARK OF MISFIRING CYLINDER |

-

Change the installed spark plug to a spark plug that functions normally.

-

Perform a spark test.

CAUTION:

Always disconnect each injector connector.

NOTICE:

Do not crank the engine for more than 2 seconds.

-

Install the spark plug to the ignition coil and connect the ignition coil connector.

-

Disconnect the injector connector.

-

Ground the spark plug.

-

Check if sparks occur while the engine is being cranked.

OK:

Sparks jump across electrode gap.

-

|

|

||||

| OK | ||

|

||

| 9.CHECK AIR INDUCTION SYSTEM |

-

Check the air induction system for vacuum leakage.

OK:

No leakage from air induction system.

|

|

||||

| OK | |

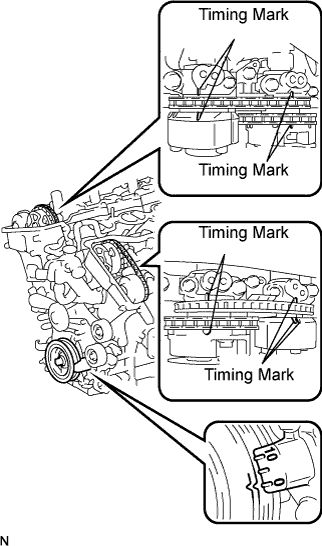

| 10.CHECK VALVE TIMING |

-

Remove the cylinder head covers.

-

Turn the crankshaft pulley, and align its groove with the timing mark "0" of the timing chain cover.

-

Check that the timing marks of the camshaft timing gears aligned with the timing marks of the bearing cap as shown in the illustration.

If not, turn the crankshaft 1 revolution (360°) and align the marks as above.OK:

Timing marks on camshaft timing gears are aligned as shown in illustration.

-

Reinstall the cylinder head covers.

|

|

||||

| OK | |

| 11.CHECK FUEL PRESSURE (LOW PRESSURE SIDE) |

-

Check the fuel pressure (low pressure side) .

|

|

||||

| OK | |

| 12.CHECK FUEL PRESSURE (HIGH PRESSURE SIDE) |

-

Check the fuel pressure (high pressure side) .

|

|

||||

| OK | |

| 13.READ VALUE OF INTELLIGENT TESTER (COOLANT TEMP) |

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the tester ON.

-

Enter the following menus: Power train / Engine / Data List / Coolant Temp.

-

Read the COOLANT TEMP twice, when the engine is both cold and warmed up.

Standard:

With cold engine:

Same as ambient air temperature.

With warm engine:

Between 75°C and 95°C (167°F and 203°F).

|

|

||||

| OK | |

| 14.READ VALUE OF INTELLIGENT TESTER (MAF) |

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the tester ON.

-

Enter the following menus: Power train / Engine / Data List / MAF and Coolant Temp.

-

Allow the engine to idle until the COOLANT TEMP reaches 75°C (167°F) or more.

-

Read the MAF with the engine in an idling condition and at an engine speed of 2,500 rpm.

Standard:

MAF while engine idling:

Between 2.1 g/s and 3.1 g/s (shift position: N, A/C: OFF).

MAF at engine speed of 2,500 rpm:

Between 7.8 g/s and 11.4 g/s (shift position: N, A/C: OFF).

|

|

||||

| OK | ||

|

||