READ VALUE OF INTELLIGENT TESTER (OUTPUT VOLTAGE OF HEATED OXYGEN SENSOR)

CHECK HARNESS AND CONNECTOR (CHECK FOR SHORT)

INSPECT HEATED OXYGEN SENSOR (CHECK FOR SHORT)

PERFORM CONFIRMATION DRIVING PATTERN

CHECK WHETHER DTC OUTPUT RECURS (DTC P0138 or P0158)

READ VALUE OF INTELLIGENT TESTER (OUTPUT VOLTAGE OF HEATED OXYGEN SENSOR)

PERFORM CONFIRMATION DRIVING PATTERN

CHECK WHETHER DTC OUTPUT RECURS (DTC P0136 or P0156)

PERFORM CONFIRMATION DRIVING PATTERN

CHECK WHETHER DTC OUTPUT RECURS (DTC P0136 or P0156)

PERFORM ACTIVE TEST BY INTELLIGENT TESTER (INJECTION VOLUME)

INSPECT HEATED OXYGEN SENSOR (HEATER RESISTANCE)

INSPECT INTEGRATION RELAY (EFI MAIN RELAY)

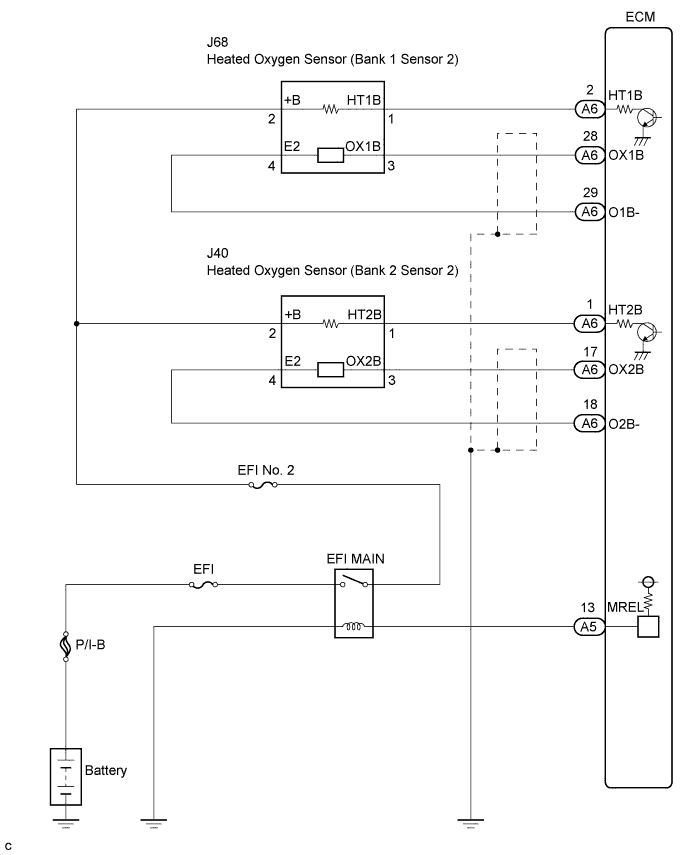

CHECK HARNESS AND CONNECTOR (HEATED OXYGEN SENSOR - ECM)

DTC P0136 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 2)

DTC P0137 Oxygen Sensor Circuit Low Voltage (Bank 1 Sensor 2)

DTC P0138 Oxygen Sensor Circuit High Voltage (Bank 1 Sensor 2)

DTC P0156 Oxygen Sensor Circuit Malfunction (Bank 2 Sensor 2)

DTC P0157 Oxygen Sensor Circuit Low Voltage (Bank 2 Sensor 2)

DTC P0158 Oxygen Sensor Circuit High Voltage (Bank 2 Sensor 2)

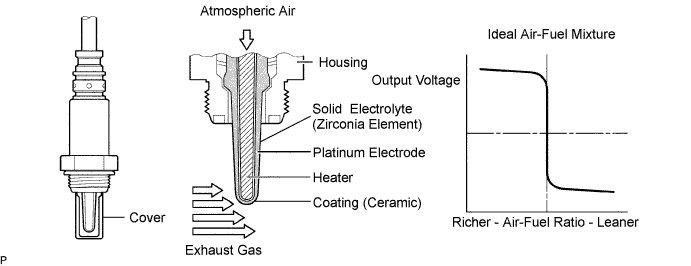

Description

HINT:

Sensor 2 refers to the sensor mounted behind the Three-Way Catalyst Converter (TWC) and located far from the engine assembly.

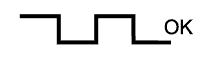

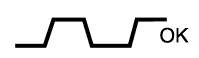

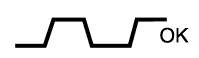

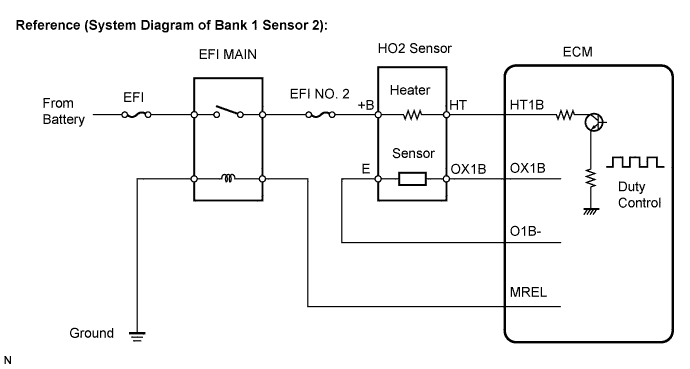

In order to obtain a high purification rate of the carbon monoxide (CO), hydrocarbon (HC) and nitrogen oxide (NOx) components in the exhaust gas, a TWC (Three-Way Catalytic Converter) is used. For the most efficient use of the TWC, the air-fuel ratio must be precisely controlled so that it is always close to the stoichiometric air-fuel level. For the purpose of helping the ECM to deliver accurate air-fuel ratio control, a Heated Oxygen (HO2) sensor is used. The HO2 sensor is located behind the TWC, and detects the oxygen concentration in the exhaust gas. Since the sensor is integrated with the heater that heats the sensing portion, it is possible to detect the oxygen concentration even when the intake air volume is low (the exhaust gas temperature is low). When the air-fuel ratio becomes lean, the oxygen concentration in the exhaust has is rich. The HO2 sensor informs the ECM that the post-TWC air-furl ratio is lean (low voltage, i.e. less than 0.45 V). Conversely, when the air-fuel ratio is richer than the stoichiometric air-fuel level, the oxygen concentration in the exhaust gas becomes lean. The HO2 sensor informs the ECM that the post-TWC air-fuel ratio is rich (high voltage, i.e. more than 0.45 V). The HO2 sensor has the property of changing its output voltage drastically when the air-fuel ratio is close to the stoichiometric level. The ECM uses the supplementary information from the HO2 sensor to determine whether the air-fuel ratio after the TWC is rich or lean, and adjusts the fuel injection time accordingly. Thus, if the HO2 sensor is working improperly due to internal malfunctions. The ECM is unable to compensate for deviations in the primary air-fuel ratio control.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0136*1 P0156*1 |

During active air-fuel ratio control, following conditions (a) and (b) are met for certain period of time (2 trip detection logic) (a) Heated Oxygen sensor voltage does not decrease to less than 0.25 V. Heated Oxygen sensor voltage does not increase to more than 0.59 V. |

|

| P0136*2 P0156*2 |

|

|

| P0137*1 P0157 |

|

|

| P0138*1 P0158 |

|

|

*1: For Europe and Australia *2: For Turkey

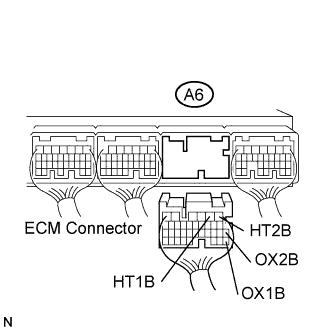

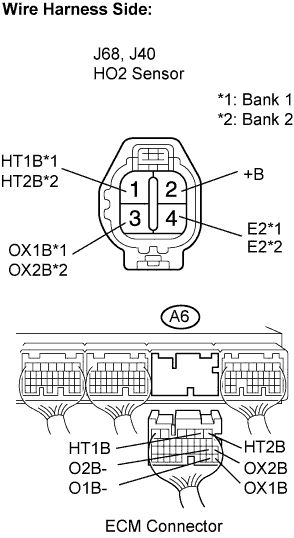

Wiring diagram

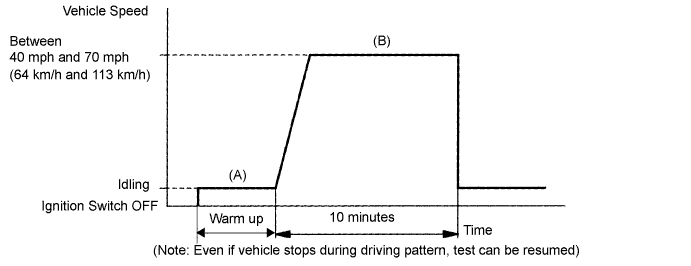

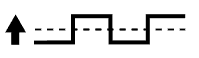

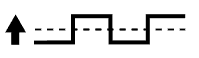

CONFIRMATION DRIVING PATTERN

- For Europe and Australia:

HINT:

- This confirmation driving pattern is used in steps 5, 8 and 11 of the following diagnostic troubleshooting procedure when using an intelligent tester.

- Performing this confirmation pattern will activate the Heated Oxygen (HO2) sensor monitor. (The catalyst monitor is performed simultaneously.) This is very useful for verifying the completion of a repair.

NOTICE:

This test will not be completed if the vehicle is driven under absolutely constant speed conditions such as with cruise control activated.

- Connect an intelligent tester to the DLC3.

- Turn the engine switch on (IG).

- Turn the tester on.

- Clear DTCs (where set) .

- Start the engine and warm it up (Procedure "A").

- Drive the vehicle at between 40 mph and 70 mph (64 km/h and 113 km/h) for at least 10 minutes (Procedure "B").

- On the tester, select the following menu items: Powertrain / Engine / DTC / Pending and check if any DTCs (any pending DTCs) are set.

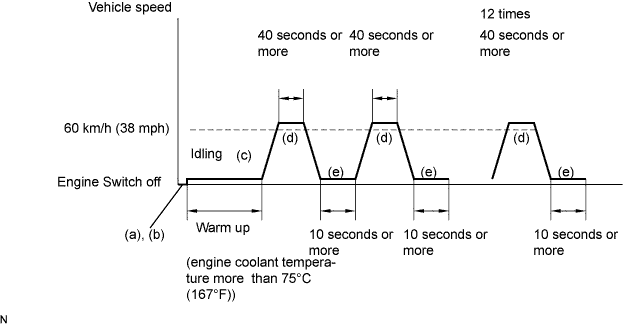

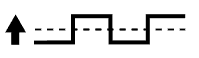

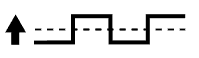

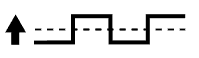

- For Turkey:

- (a) Connect the intelligent tester to the DLC3.

- (b) Switch the ECM From normal mode to check mode using the tester .

- (c) Start the engine and warm it up until the engine coolant temperature reaches more than 75°C (167°F).

- (d) Drive the vehicle at 60 km/h (38 mph) or more for 40 seconds or more.

- (e) Let the engine idle for 10 seconds or more.

- (f) Perform steps (d) and (e) 12 times.

HINT:

If a malfunction exists, the MIL illuminates during step (f).

NOTICE:

If the conditions in this test are not strictly followed, malfunctions may not be detected. If you do not have the intelligent tester, turn the engine switch off after performing steps from (c) to (f), then perform steps (c) to (f) again.

Inspection procedure

HINT:

Intelligent tester only:

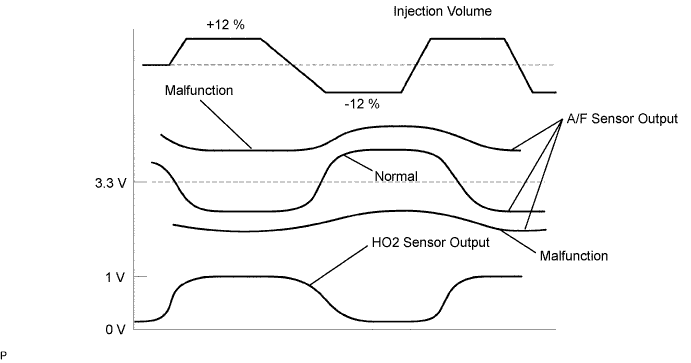

Malfunctioning areas can be identified by performing the Control the Injection Volume for A/F Sensor function provided in the Active Test. The Control the Injection Volume for A/F Sensor function can help to determine whether the Air-Fuel Ratio (A/F) sensor, Heated Oxygen (HO2) sensor and other potential trouble areas are malfunctioning.

The following instructions describe how to conduct the Control the Injection Volume for A/F Sensor operation using an intelligent tester.

- Connect the intelligent tester to the DLC3.

- Start the engine and turn the tester ON.

- Warm up the engine at engine speed of 2,500 rpm for approximately 90 seconds.

- On the tester, enter the following menus: Power train / Engine / Active Test / Control the Injection Volume for A/F Sensor.

- Perform the Control the Injection Volume for A/F Sensor operation with the engine in an idling condition (press the RIGHT or LEFT button to change the fuel injection volume).

- Monitor the voltage outputs of the A/F and HO2 sensors (AFS B1S1 and O2S B1S2 or AFS B2S1 and O2S B2S2) displayed on the tester.

HINT:

- The Control the Injection Volume for A/F Sensor operation lowers the fuel injection volume by 12.5 % or increases the injection volume by 25 %.

- Each sensor reacts in accordance with increases in the fuel injection volume.

| Tester Display (Sensor) | Injection Volume | Status | Voltage |

| AFS B1S1 or AFS B2S1 (A/F) |

+25 % | Rich | Less than 3.0 |

| AFS B1S1 or AFS B2S1 (A/F) |

-12.5 % | Lean | More than 3.35 |

| O2S B1S2 or O2S B2S2 (HO2) |

+25 % | Rich | More than 0.55 |

| O2S B1S2 or O2S B2S2 (HO2) |

-12.5 % | Lean | Less than 0.4 |

NOTICE:

The Air-Fuel Ratio (A/F) sensor has an output delay of a few seconds and the Heated Oxygen (HO2) sensor has a maximum output delay of approximately 20 seconds.

| Case | A/F Sensor (Sensor 1) Output Voltage |

HO2 Sensor (Sensor 2) Output Voltage |

Main Suspected Trouble Area | ||

| 1 | Injection Volume +25 % -12.5 % |

|

Injection Volume +25 % -12.5 % |

|

- |

| Output Voltage More than 3.35 V Less than 3.0 V |

|

Output Voltage More than 0.55 V Less than 0.4 V |

|

||

| 2 | Injection Volume +25 % -12.5 % |

|

Injection Volume +25 % -12.5 % |

|

|

| Output Voltage Almost no reaction |

|

Output Voltage More than 0.55 V Less than 0.4 V |

|

||

| 3 | Injection Volume +25 % -12.5 % |

|

Injection Volume +25 % -12.5 % |

|

|

| Output Voltage More than 3.35 V Less than 3.0 V |

|

Output Voltage Almost no reaction |

|

||

| 4 | Injection volume +25 % -12.5 % |

|

Injection Volume +25 % -12.5 % |

|

|

| Output Voltage Almost no reaction |

|

Output Voltage Almost no reaction |

|

||

- Following the Control the Injection Volume for A/F Sensor procedure enables technicians to check and graph the voltage outputs of both the A/F and HO2 sensors.

- The following A/F Control procedure enables the technician to check and graph the voltage output of both the heated oxygen sensors. To display the graph, select the following menu items on the tester: View / Line Graph.

HINT:

- If other DTCs relating to different systems that have terminal E2 as the ground terminal are output simultaneously, terminal E2 may have an open circuit.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

- If the OX1B wire from the ECM connector is short-circuited to the +B wire, DTC P0136 will be set.

- If the OX2B wire from the ECM connector is short-circuited to the +B wire, DTC P0156 will be set.

| 1.READ OUTPUT DTC |

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG) and turn the tester ON.

-

Enter the following menus: Power train / Engine / DTC.

-

Read DTCs.

Result:

Display (DTC Output) Proceed to P0138 or P0158 A P0136 or P0156 B

|

|

||||

| A | |

| 2.READ VALUE OF INTELLIGENT TESTER (OUTPUT VOLTAGE OF HEATED OXYGEN SENSOR) |

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG) and turn the tester ON.

-

Enter the following menus: Power train / Engine / Data List / O2S B1 S2 or O2S B2 S2.

-

Allow the engine to idle.

-

Read the Heated Oxygen (HO2) sensor output voltage while idling.

Result:

HO2 Sensor Output Voltage Proceed to More than 1.2 V A Less than 1.0 V B

|

|

||||

| A | |

| 3.CHECK HARNESS AND CONNECTOR (CHECK FOR SHORT) |

-

Turn the engine switch off and wait for 5 minutes.

-

Disconnect the A6 ECM connector.

-

Measure the resistance.

Standard resistance:

Tester Connection Specified Condition HT1B (A6-2) - OX1B (A6-28) 10 k? or higher HT2B (A6-1) - OX2B (A6-17) 10 k? or higher

-

Reconnect the ECM connector.

|

|

||||

| OK | ||

|

||

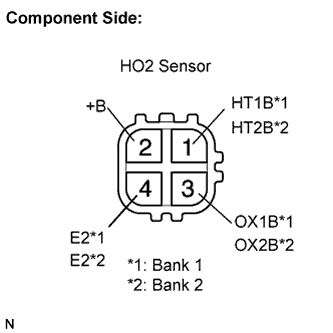

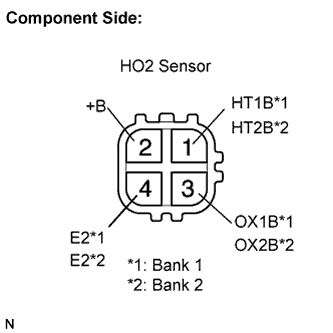

| 4.INSPECT HEATED OXYGEN SENSOR (CHECK FOR SHORT) |

-

Disconnect the J68 or J40 HO2 sensor connector.

-

Measure the resistance.

Standard resistance (Bank 1 sensor 2):

Tester Connection Specified Condition +B (2) - E2 (4) 10 k? or higher +B (2) - OX1B (3) 10 k? or higher Standard resistance (Bank 2 sensor 2):

Tester Connection Specified Condition +B (2) - E2 (4) 10 k? or higher +B (2) - OX2B (3) 10 k? or higher

|

|

||||

| OK | |

| 5.PERFORM CONFIRMATION DRIVING PATTERN |

| NEXT | |

| 6.CHECK WHETHER DTC OUTPUT RECURS (DTC P0138 or P0158) |

-

On the intelligent tester, enter the following menus: Power train / Engine / DTC.

-

Read DTCs.

Result:

Display (DTC Output) Proceed to P0138 or P0158 A No output B

|

|

||||

| A | ||

|

||

| 7.READ VALUE OF INTELLIGENT TESTER (OUTPUT VOLTAGE OF HEATED OXYGEN SENSOR) |

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG) and turn the tester ON.

-

Start the engine.

-

Enter the following menus: Power train / Engine / Data List / O2S B1 S2 or O2S B1 S2.

-

After warming up the engine, run the engine at an engine speed of 2,500 rpm for 3 minutes.

-

Read the output voltage of the HO2 sensor when the engine rpm is suddenly increased.

HINT:

Quickly accelerate the engine to 4,000 rpm 3 times using the accelerator pedal.

Standard voltage:

Fluctuates between 0.4 V or less and 0.5 V or more.

|

|

||||

| OK | |

| 8.PERFORM CONFIRMATION DRIVING PATTERN |

| NEXT | |

| 9.CHECK WHETHER DTC OUTPUT RECURS (DTC P0136 or P0156) |

-

On the intelligent tester, enter the following menus: Power train / Engine / DTC.

-

Read DTCs.

Result:

Display (DTC Output) Proceed to P0136 or P0156 A No output B

|

|

||||

| A | |

| 10.REPLACE HEATED OXYGEN SENSOR |

| NEXT | |

| 11.PERFORM CONFIRMATION DRIVING PATTERN |

| NEXT | |

| 12.CHECK WHETHER DTC OUTPUT RECURS (DTC P0136 or P0156) |

-

On the intelligent tester, enter the following menus: Power train / Engine / DTC.

-

Read DTCs.

Result:

Display (DTC Output) Proceed to P0136 or P0156 A No output B

|

|

||||

| A | |

| 13.PERFORM ACTIVE TEST BY INTELLIGENT TESTER (INJECTION VOLUME) |

-

Connect the intelligent tester to the DLC3.

-

Start the engine and turn the tester ON.

-

Warm up the engine.

-

Enter the following menus: Power train / Engine / Active Test / Control the Injection Volume.

-

Change the fuel injection volume using the tester, monitoring the output voltage of Air-Fuel Ratio (A/F) and HO2 sensor displayed on the tester.

HINT:

- Change the fuel injection volume within the range of -12 % and +12 %. The injection volume can be changed in 1 % graduations within the range.

- The A/F sensor is displayed as AFS B1 S1 or AFS B2 S1, and the HO2 sensor is displayed as O2S B1 S2 or O2S B2 S2, on the intelligent testers.

Result:

Tester Display (Sensor) Voltage Variation Proceed to AFS B1S1 (A/F)

AFS B2S1 (A/F)Alternates between more and less than 3.3 V OK AFS B1S1 (A/F)

AFS B2S1 (A/F)Remains at more than 3.3 V NG AFS B1S1 (A/F)

AFS B2S1 (A/F)Remains at less than 3.3 V NG HINT:

A normal HO2 sensor voltage (O2S B1 S2 or O2S B2 S2) reacts in accordance with increases and decreases in fuel injection volumes. When the A/F sensor voltage remains at either less or more than 3.3 V despite the HO2 sensor indicating a normal reaction, the A/F sensor is malfunctioning.

|

|

||||

| OK | ||

|

||

| 14.CHECK EXHAUST GAS LEAKAGE |

OK:

No gas leakage.

|

|

||||

| OK | |

| 15.INSPECT HEATED OXYGEN SENSOR (HEATER RESISTANCE) |

-

Disconnect the J68 or J40 HO2 sensor connector.

-

Measure the resistance.

Standard resistance (Bank 1 sensor 2):

Tester Connection Condition Specified Condition HT1B (1) - +B (2) 20°C (68°F) 11 to 16 ? HT1B (1) - E2 (4) - 10 k? or higher Standard resistance (Bank 2 sensor 2):

Tester Connection Condition Specified Condition HT2B (1) - +B (2) 20°C (68°F) 11 to 16 ? HT2B (1) - E2 (4) - 10 k? or higher

|

|

||||

| OK | |

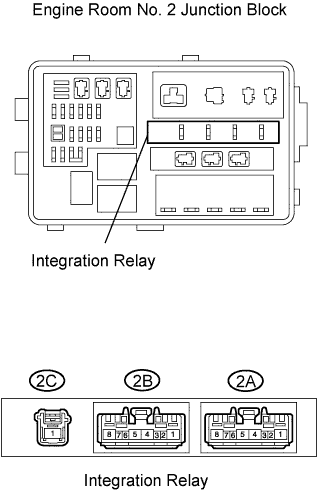

| 16.INSPECT INTEGRATION RELAY (EFI MAIN RELAY) |

-

Remove the integration relay from the engine room No. 2 junction block.

-

Measure the resistance of the EFI MAIN relay.

Standard resistance:

Terminal Connection Specified Condition 2A-8 - 2A-5 10 k? or higher 2A-8 - 2A-5 Below 1 ?

(when battery voltage applied to terminals 2A-7 and 2A-6)

-

Reinstall the integration relay.

|

|

||||

| OK | |

| 17.CHECK HARNESS AND CONNECTOR (HEATED OXYGEN SENSOR - ECM) |

-

Disconnect the J68 and J40 HO2 sensor connector.

-

Turn the engine switch on (IG).

-

Measure the voltage between the +B terminal of the HO2 sensor connector and body ground.

Standard voltage:

Terminal Connection Specified Condition +B (J68-2) - Body ground 9 to 14 V +B (J40-2) - Body ground 9 to 14 V

-

Turn the engine switch off.

-

Disconnect the A6 ECM connector.

-

Measure the resistance.

Standard resistance (Check for open):

Terminal Connection Specified Condition HT1B (J68-1) - HT1B (A6-2) Below 1 ? OX1B (J68-3) - OX1B (A6-28) Below 1 ? E2 (J68-4) - O1B- (A6-29) Below 1 ? HT2B (J40-1) - HT2B (A6-1) Below 1 ? OX2B (J40-3) - OX2B (A6-17) Below 1 ? E2 (J40-4) - O2B- (A6-18) Below 1 ? Standard resistance (Check for short):

Terminal Connection Specified Condition HT1B (J68-1) or HT1B (A6-2) - Body ground 10 k? or higher OX1B (J68-3) - OX1B (A6-28) - Body ground 10 k? or higher E2 (J68-4) or O1B- (A6-29) - Body ground 10 k? or higher HT2B (J40-1) or HT2B (A6-1) - Body ground 10 k? or higher OX2B (J40-3) or OX2B (A6-17) - Body ground 10 k? or higher E2 (J40-4) or O2B- (A6-18) - Body ground 10 k? or higher

-

Reconnect the HO2 sensor connector.

-

Reconnect the ECM connector.

|

|

||||

| OK | ||

|

||