Dtc P0088 Fuel Rail / System Pressure - Too High

DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT FUEL SUPPLY PUMP (SUCTION CONTROL VALVE)

READ VALUE USING INTELLIGENT TESTER

READ VALUE USING INTELLIGENT TESTER (FUEL PRESS)

REPLACE PRESSURE LIMITER (COMMON RAIL (for Bank 2))

CHECK HARNESS AND CONNECTOR (SUCTION CONTROL VALVE CONNECTOR - ECM)

REPLACE FUEL SUPPLY PUMP

CHECK DTC OUTPUT

REPLACE ECM

REPAIR OR REPLACE HARNESS OR CONNECTOR

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P0088 Fuel Rail / System Pressure - Too High |

DESCRIPTION

Refer to System Description (Click here).P0088DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

After idling for 60 seconds, repeat quick engine speed accelerations (to 2500 rpm) for 30 seconds

| The fuel pressure of common rail is too high

The fuel pressure exceeds 230 MPa (2345 kgf/cm2, 33358 psi) (1 trip detection logic).

| - Fuel supply pump (suction control valve)

- Pressure limiter (common rail (for Bank 2))

- Open or short in fuel supply pump (suction control valve) circuit

- ECM

|

Related Data ListDTC No.

| Data List

|

P0088

| - Fuel Press

- Target Common Rail Pressure

- Injection Pressure Correction

- Target Pump SCV Current

|

- HINT:

- For more information on the fuel supply pump (suction control valve) and common rail system, refer to System Description (Click here).

- When DTC P0088 is stored, check the internal fuel pressure of the common rail by entering the following menus: Powertrain / Engine / Data List / Fuel Press.

ReferenceEngine Speed

| Fuel Press

|

Idling

| Approximately 27 to 37 MPa

|

2500 rpm (No engine load)

| Approximately 50 to 70 MPa

|

- When there is an operating problem with the fuel supply pump (when Fuel Press is more than Target Common Rail Pressure due to a problem with the closing of the suction valve), the values of Injection Pressure Correction and Target Pump SCV Current decrease.

MONITOR DESCRIPTION

- P0088 (Internal fuel pressure too high):

The ECM stores this DTC if the fuel pressure inside the common rail is more than 230 MPa (2345 kgf/cm2, 33350 psi). This DTC indicates that: 1) the suction control valve may be stuck open, or 2) there may be a short in the suction control valve circuit.

If this DTC is stored, the ECM enters fail-safe mode and limits the engine power. The fail-safe mode continues until the ignition switch is turned off.

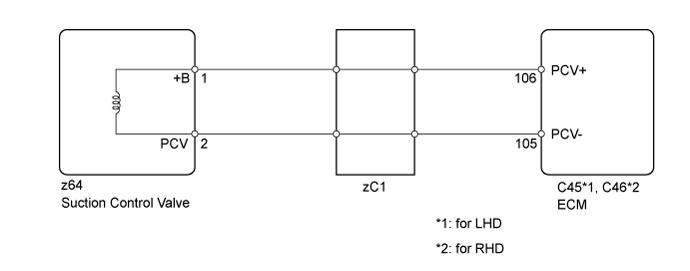

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- After replacing the ECM, the new ECM needs registration (Click here) and initialization (Click here).

- After replacing the fuel supply pump, the ECM needs initialization (Click here).

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.INSPECT FUEL SUPPLY PUMP (SUCTION CONTROL VALVE) |

Disconnect the suction control valve connector and then start the engine.

- OK:

- Engine does not start.

| 2.READ VALUE USING INTELLIGENT TESTER |

Connect the intelligent tester to the DLC3.

Start the engine.

Turn the tester on.

Enter the following menus: Powertrain / Engine / Data List / Target Pump SCV Current.

Read the value.

StandardEngine Speed

| Target Pump SCV Current

|

Idling

| 923 to 1123 mA

|

2500 rpm (No engine load)

| 1013 to 1212 mA

|

| 3.READ VALUE USING INTELLIGENT TESTER (FUEL PRESS) |

Connect the intelligent tester to the DLC3.

Start the engine.

Turn the tester on.

Enter the following menus: Powertrain / Engine / Data List / Fuel Press, Target Common Rail Pressure.

Check the difference in pressure between Fuel Press and Target Common Rail Pressure.

- OK:

- Difference in pressure between Fuel Press and Target Common Rail Pressure is within +/-5 MPa.

| 4.REPLACE PRESSURE LIMITER (COMMON RAIL (for Bank 2)) |

Replace the common rail (for Bank 2) (Click here).

| 5.CHECK HARNESS AND CONNECTOR (SUCTION CONTROL VALVE CONNECTOR - ECM) |

Disconnect the suction control valve connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for open):

for LHDTester Connection

| Condition

| Specified Condition

|

z64-2 (PCV) - C45-105 (PCV-)

| Always

| Below 1 Ω

|

z64-1 (+B) - C45-106 (PCV+)

| Always

| Below 1 Ω

|

for RHDTester Connection

| Condition

| Specified Condition

|

z64-2 (PCV) - C46-105 (PCV-)

| Always

| Below 1 Ω

|

z64-1 (+B) - C46-106 (PCV+)

| Always

| Below 1 Ω

|

- Standard Resistance (Check for short):

for LHDTester Connection

| Condition

| Specified Condition

|

z64-2 (PCV) or C45-105 (PCV-) - Body ground

| Always

| 10 kΩ or higher

|

z64-1 (+B) or C45-106 (PCV+) - Body ground

| Always

| 10 kΩ or higher

|

for RHDTester Connection

| Condition

| Specified Condition

|

z64-2 (PCV) or C46-105 (PCV-) - Body ground

| Always

| 10 kΩ or higher

|

z64-1 (+B) or C46-106 (PCV+) - Body ground

| Always

| 10 kΩ or higher

|

| 6.REPLACE FUEL SUPPLY PUMP |

Replace the fuel supply pump (Click here).

Connect the intelligent tester to the DLC3.

Clear the DTCs (Click here).

Turn the ignition switch off.

Start the engine.

After idling for 60 seconds, repeat engine speed accelerations (from idling to 2500 rpm) for 30 seconds.

Enter the following menus: Powertrain / Engine / DTC.

Read the DTCs.

ResultDisplay (DTC output)

| Proceed to

|

P0088 is output

| A

|

No DTC is output

| B

|

Replace the ECM (Click here).

| 9.REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 10.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the intelligent tester to the DLC3.

Clear the DTCs (Click here).

Turn the ignition switch off.

Turn the ignition switch to ON and start the engine.

After idling for 60 seconds, repeat engine speed accelerations (from idling to 2500 rpm) for 30 seconds.

Confirm that the DTC is not output again.

- HINT:

- Perform the following procedure using the tester to determine whether or not the DTC judgment has been carried out.

Enter the following menus: Powertrain / Engine / Utility / All Readiness.

Input DTC P0088.

Check that STATUS is NORMAL. If STATUS is INCOMPLETE or UNKNOWN, race the engine to 2500 rpm repeatedly for 30 seconds and increase idling time.