Fuel supply pump 2AD-FHV

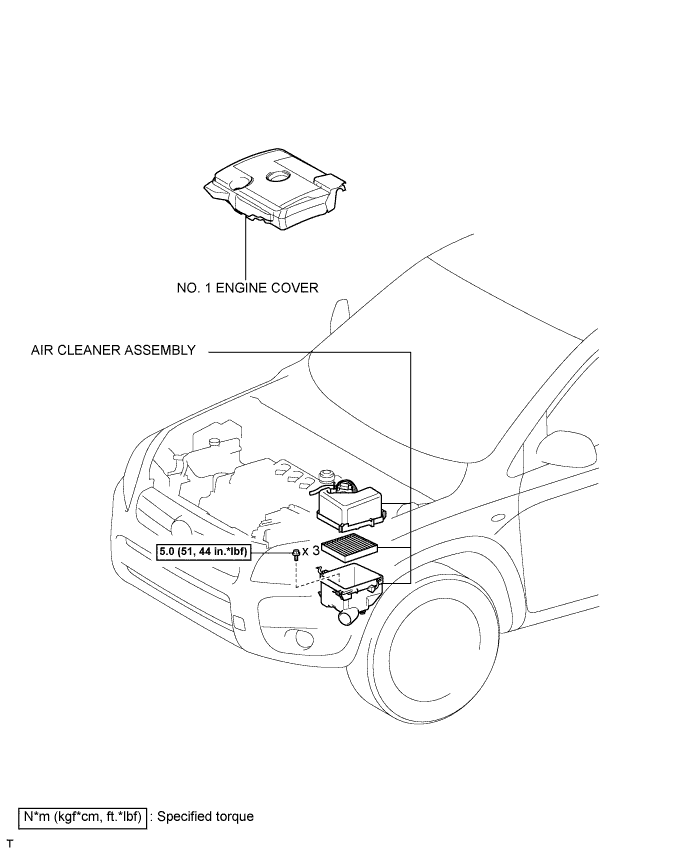

Components

Fuel supply pump 2AD-FHV

Removal

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

-

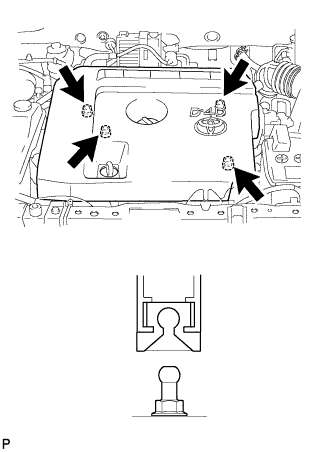

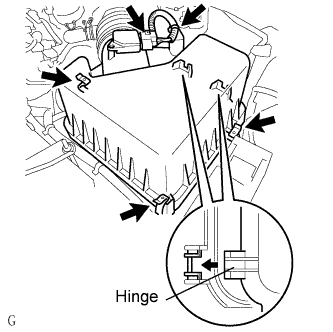

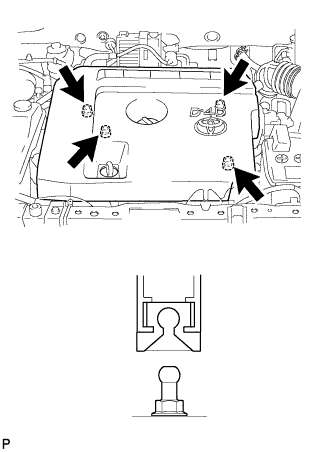

Detach the 4 clips and remove the engine cover.

-

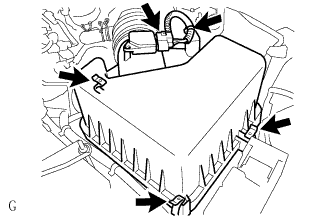

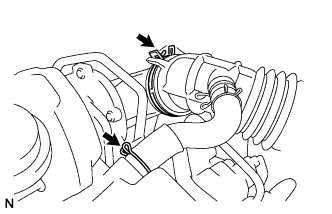

Disconnect the mass air flow meter connector.

-

Unhook the 3 hook clamps.

-

Disengage the wire harness clamp.

-

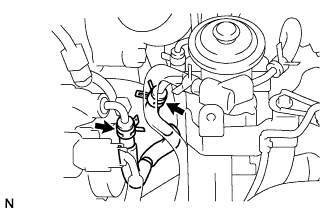

Using pliers, grip the claws of the clip and slide the clip to disconnect the PCV hose from the cylinder head cover.

-

Using pliers, grip the claws of the clip to remove the air cleaner cap.

-

Remove the air filter element.

-

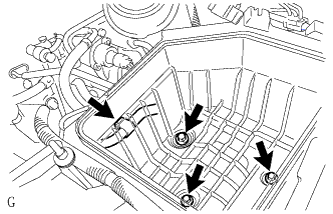

Disconnect the wire harness clamp and remove the 3 bolts and air cleaner case.

-

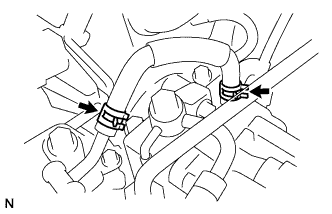

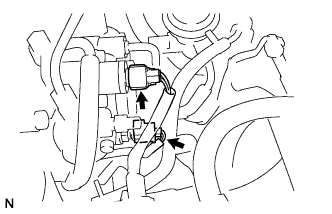

Using pliers, grip the claws of the 2 clips and slide the 2 clips to remove the No. 3 fuel hose.

-

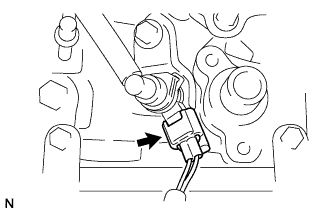

Disconnect the exhaust fuel addition injector connector.

-

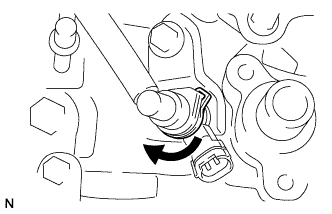

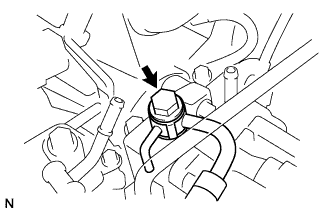

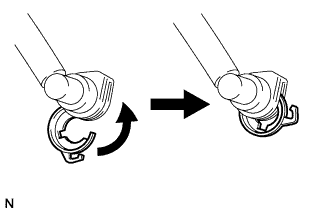

Turn the retainer as shown in the illustration.

-

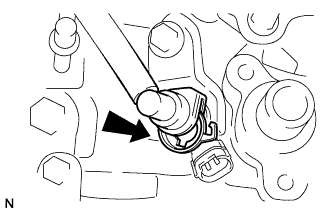

Disconnect the fuel tube from the exhaust fuel addition injector connector.

-

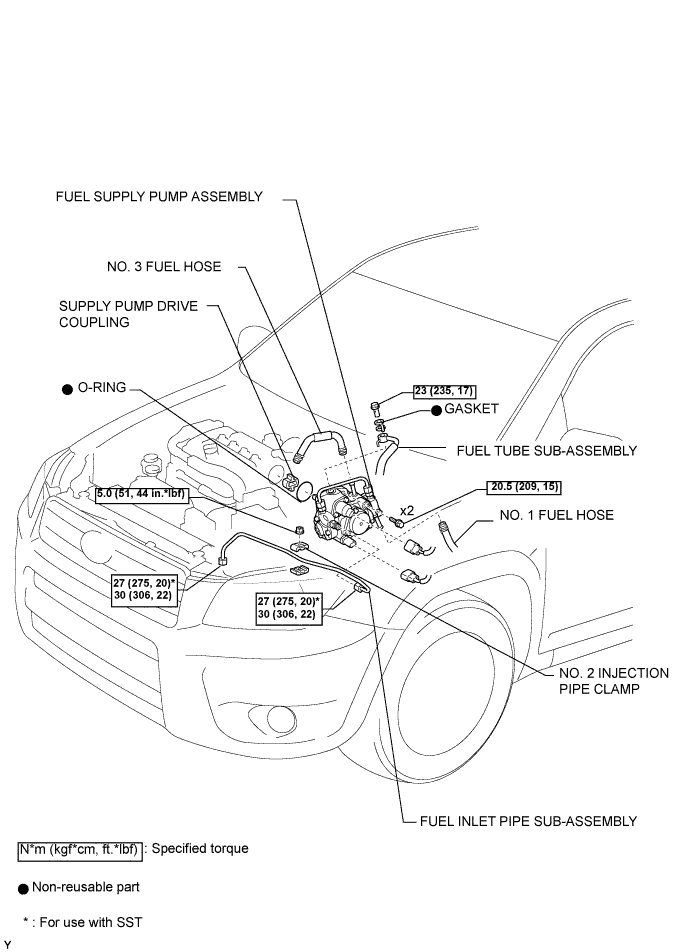

Remove the union bolt, gasket and fuel tube.

-

Using pliers, grip the claws of the 2 clips and slide the 2 clips to remove the No. 1 fuel hose.

NOTICE:

After removing the fuel inlet pipe, cover the common rail and supply pump with electrical tape to prevent dirt from entering them.

-

Remove the nut and fuel inlet pipe clamps.

-

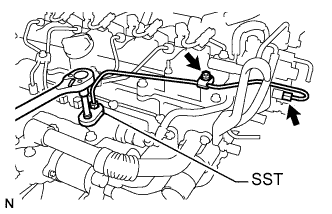

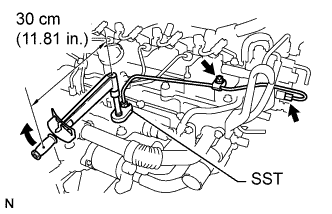

Using SST, remove the fuel inlet pipe.

SST:

09023-38401

-

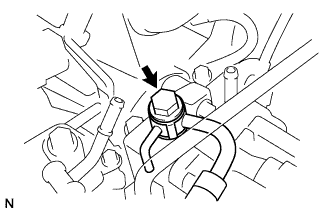

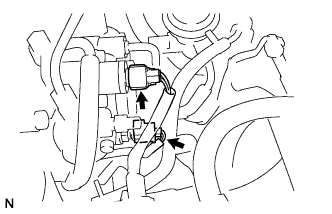

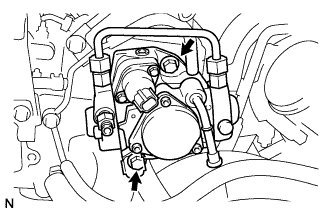

Disconnect the fuel temperature sensor connector.

-

Disconnect the suction control valve connector.

-

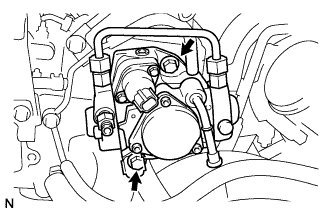

Remove the 2 bolts to remove the supply pump, O-ring and supply pump drive coupling from the cylinder head.

-

Remove the O-ring from the supply pump.

Fuel supply pump 2AD-FHV

Inspection

-

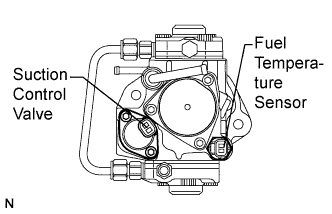

Inspect the suction control valve.

-

Measure the resistance of the valve.

Standard resistance:

Tester Connection Condition Specified Condition 1 - 2 20°C (68°F) 1.9 to 2.3 ? HINT:

The temperature indicated in "Condition" is the temperature of the suction control valve.

If the result is not as specified, replace the supply pump assembly. -

-

Inspect the fuel temperature sensor.

-

Measure the resistance of the sensor.

-

Standard resistance:

| Tester Connection | Condition | Specified Condition |

| 1 - 2 | 20°C (68 °F) | 2.32 to 2.59 ? |

| 1 - 2 | 80°C (176 °F) | 0.310 to 0.326 ? |

If the result is not as specified, replace the supply pump assembly.

Fuel supply pump 2AD-FHV

Installation

-

Install a new O-ring to the supply pump.

-

Install the supply pump drive coupling.

NOTICE:

When reusing the coupling, it must be installed in the same orientation (top/bottom, front/back) as when it was removed,

HINT:

Line up the coupling with the groove in the camshaft end.

-

Install the supply pump with the 2 bolts.

Torque:

20.5 N*m{ 209 kgf*cm , 15 ft.*lbf }

NOTICE:

Apply engine oil on the O-ring of the supply pump.

HINT:

Line up the end of the supply pump drive shaft with the supply pump drive coupling.

-

Connect the suction control valve connector.

-

Connect the fuel temperature sensor connector.

NOTICE:

In a case where the supply pump is replaced, the fuel inlet pipe must also be replaced.

-

Temporarily install the fuel inlet pipe with the 2 clamps and nut.

-

Using SST, first tighten the nut at the common rail end of the fuel inlet pipe.

SST:

09023-38401

Torque:

27 N*m{ 275 kgf*cm , 20 ft.*lbf }

HINT:

- Use of the proper SST is required to ensure that the correct torque is applied to the inlet pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation.

- If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new pipe.

-

Using SST, tighten the nut at the supply pump end of the fuel inlet pipe.

SST:

09023-38401

Torque:

27 N*m{ 275 kgf*cm , 20 ft.*lbf }

HINT:

- Use of the proper SST is required to ensure that the correct torque is applied to the inlet pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation.

- If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new pipe.

-

Tighten the fuel inlet pipe clamp nut.

Torque:

5.0 N*m{ 51 kgf*cm , 44 lbsf.in }

-

Install a new gasket and the fuel tube with the union bolt.

Torque:

23 N*m{ 235 kgf*cm , 17 ft.*lbf }

-

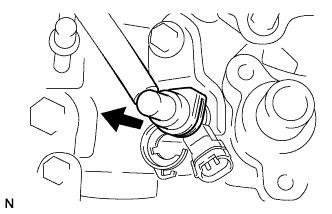

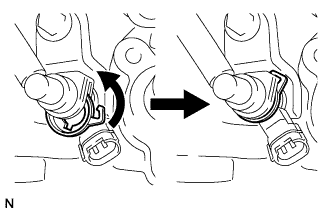

Turn the retainer in the direction indicated by the arrow until the retainer stops.

-

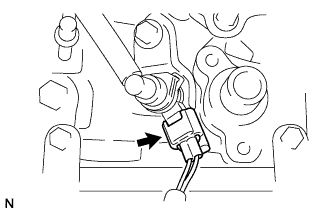

Insert the fuel tube connector into the injector.

-

Turn the retainer in the direction indicated by the arrow until it makes a "click" sound.

NOTICE:

If the fuel tube connector is not inserted to the correct position in the injector, the retainer cannot be turned farther in the direction of the arrow.

-

Connect the exhaust fuel addition injector connector.

-

Using pliers, grip the claws of the 2 clips and slide the 2 clips to install the No. 1 fuel hose.

-

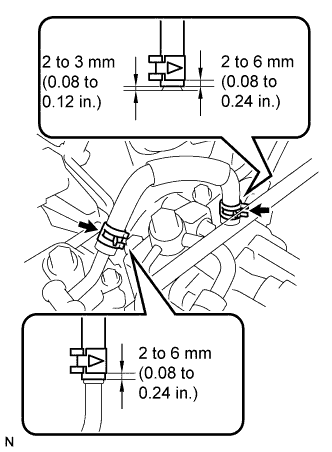

Using pliers, grip the claws of the 2 clips and slide the 2 clips to install the No. 3 fuel hose as shown in the illustration.

-

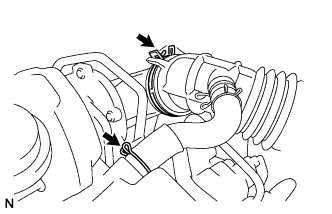

Install the cleaner case with the 3 bolts and connect the wire harness clamp.

Torque:

5.0 N*m{ 51 kgf*cm , 44 lbsf.in }

-

Install the air filter element.

-

Using pliers, grip the claws of the clip to install the air cleaner cap.

-

Using pliers, grip the claws of the clip and slide the clip to connect the PCV hose.

-

Insert the hinge parts of the air cleaner cap into the air cleaner case, and then hang the 3 hook clamps.

-

Connect the mass air flow meter connector.

-

Attach the wire harness clamp.

-

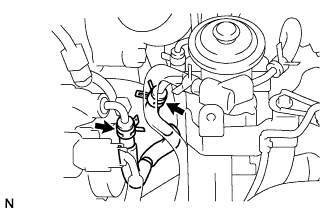

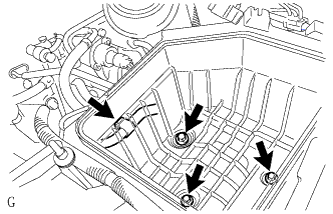

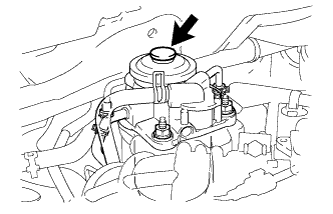

Using the hand pump indicated by the arrows in the illustration, bleed the fuel system. Continue pumping until pumping becomes difficult.

-

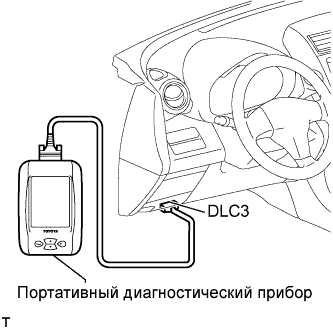

Perform the ACTIVE TEST.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG).

-

Turn the intelligent tester ON.

-

Enter the following menus: Powertrain / Engine / Active Test.

-

Perform the Active Test.

Intelligent Tester Display Test Details Control Range Diagnostic Notes Test the Fuel Leak Pressurizing common rail internal fuel pressure, and checking for fuel leaks Stop/Start - Fuel pressure inside common rail pressurized to specified value and engine speed increased to 2,000 rpm when Start is selected

- Above conditions to be maintained while test is Start

-

-

Attach the 4 clips to install the engine cover.