Fuel filter 2AD-FHV

Components

Fuel filter 2AD-FHV

Removal

-

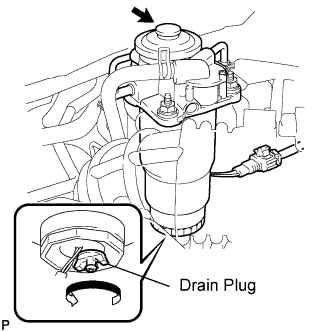

Check the fuel filter warning light.

NOTICE:

When the fuel filter warning light illuminates and the buzzer sounds, the water in the fuel filter must be drained immediately.

-

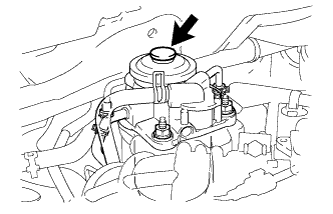

Remove the drain plug and place a small tray to catch the water.

-

Operate the hand pump until only fuel begins to run out.

-

After draining, retighten the drain plug.

NOTICE:

Do not use any tools.

-

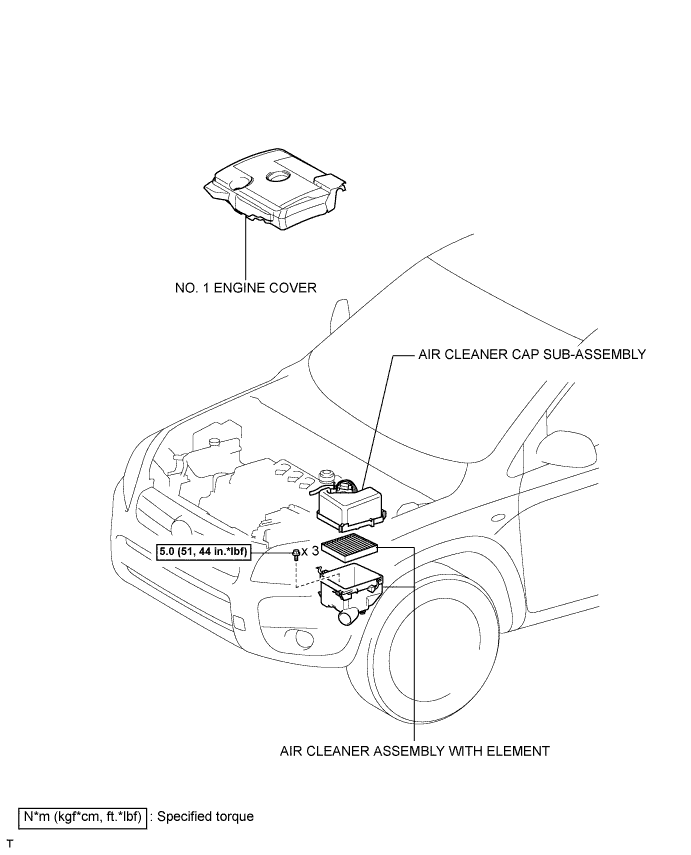

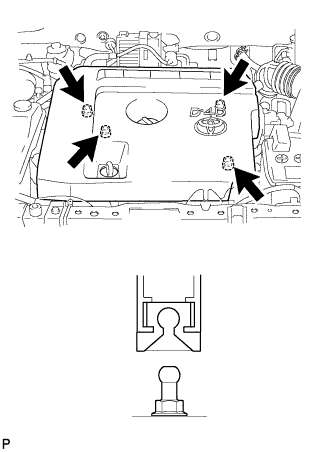

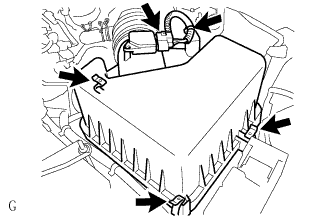

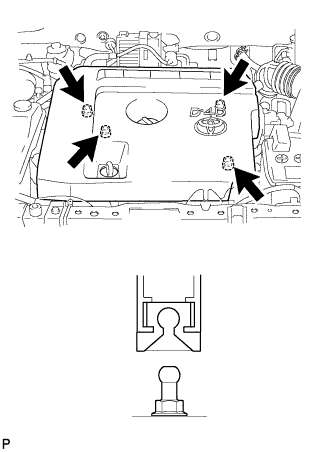

Detach the 4 clips and remove the engine cover.

-

Disconnect the mass air flow meter connector.

-

Disconnect the wire harness clamp.

-

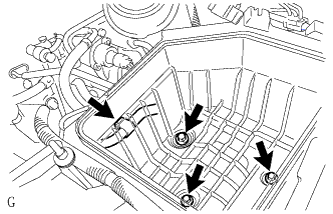

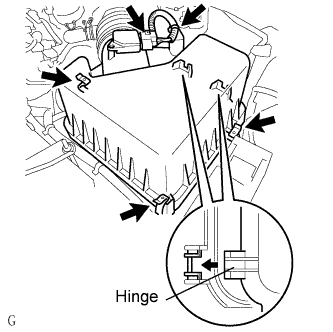

Unhook the 3 hook clamps, and then remove the air cleaner cap.

-

Remove the air cleaner filter element from the air cleaner case.

-

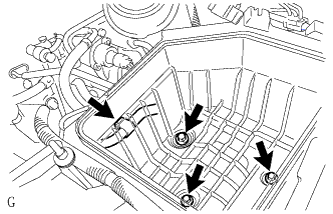

Disconnect the wire harness clamp and remove the 3 bolts and air cleaner case.

-

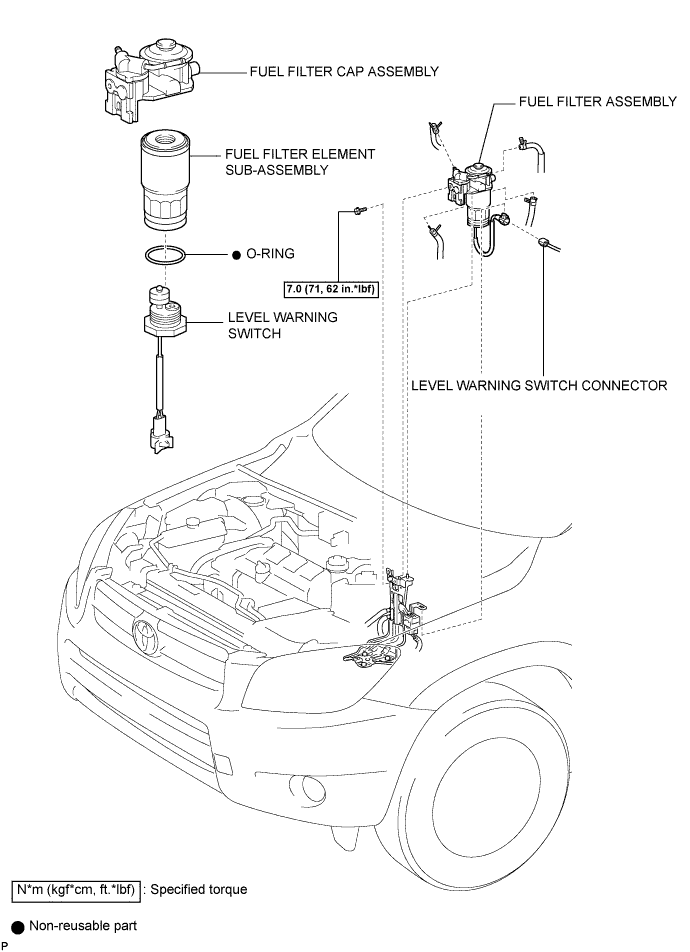

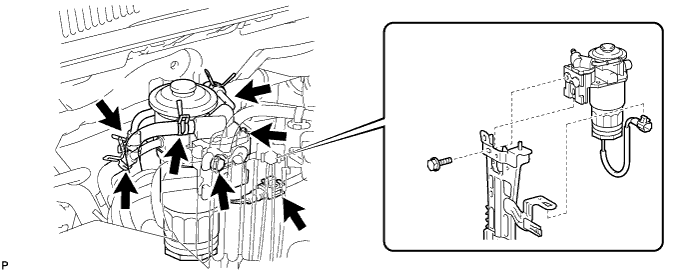

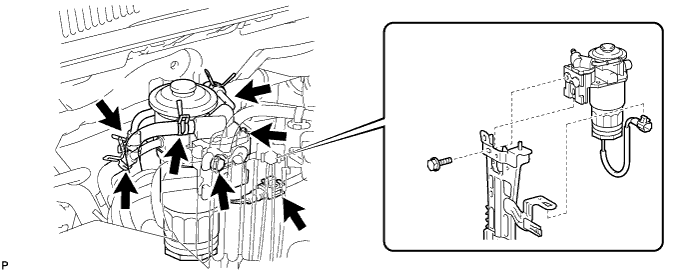

Disconnect the level warning switch connector.

-

Disconnect the 4 hoses indicated in the illustration.

-

Remove the bolt and fuel filter.

-

Loosen the drain bolt, and drain the fuel from the fuel filter.

-

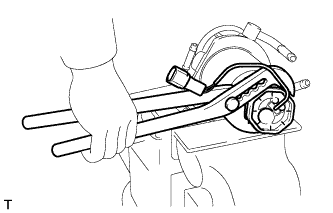

Clamp the fuel filter in a vise.

NOTICE:

Be careful not to damage the fuel filter cap.

-

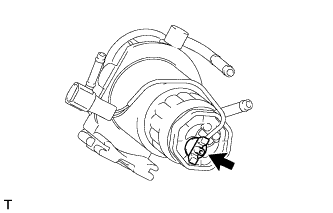

Using pliers, remove the fuel level warning switch.

NOTICE:

Be careful not to damage the level warning switch.

-

Remove the O-ring from the fuel level warning switch.

-

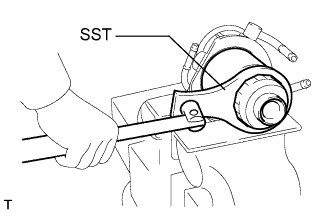

Using SST, remove the fuel filter element.

SST:

09228-64030

Fuel filter 2AD-FHV

Inspection

-

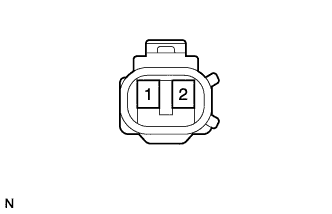

Measure the resistance of the switch.

Standard resistance:

If the result is not as specified, replace the level warning switch.Tester Connection Condition Specified Condition 1 - 2 Float is at upper end position Below 1 ? 1 - 2 Float is at lower end position 10 k? or higher

Fuel filter 2AD-FHV

Installation

-

Check and clean the installation surface of the fuel filter.

-

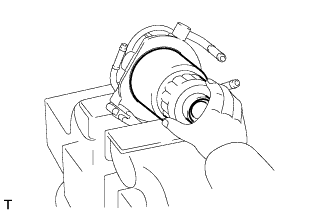

Apply fuel to the gasket of the new fuel filter element.

-

Lightly screw the fuel filter element into place, and tighten it until the gasket comes into contact with the seat.

-

Tighten it an additional 3/4 turn by hand.

-

Install a new O-ring to the level warning switch.

-

Apply fuel to the O-ring of the level warning switch.

-

Install the level warning switch to the fuel filter and tighten it by hand.

-

Install the fuel filter with the bolt.

Torque:

7.0 N*m{ 71 kgf*cm , 62 lbsf.in }

-

Connect the 4 hoses.

-

Connect the level warning switch connector.

-

Install the cleaner case with the 3 bolts and connect the wire harness clamp.

Torque:

5.0 N*m{ 51 kgf*cm , 44 lbsf.in }

-

Install the air filter element.

-

Insert the hinge parts of the air cleaner cap into the air cleaner case, and then hang the 3 hook clamps.

-

Connect the mass air flow meter connector.

-

Engage the wire harness clamp.

-

Using the hand pump, bleed air from the fuel system until pumping becomes difficult.

-

PERFORM ACTIVE TEST

-

Connect the intelligent tester to the DLC3.

-

Start the engine.

-

Turn the intelligent tester ON.

-

Enter the following menus: Powertrain / Engine / Active Test.

-

Perform the Active Test.

Intelligent Tester Display Test Details Control Range Diagnostic Notes Test the Fuel Leak Pressurizing common rail internal fuel pressure, and checking for fuel leaks Stop/Start - Fuel pressure inside common rail pressurized to specified value and engine speed increased to 2,000 rpm when start is selected

- Above conditions to be maintained while test is started

-

-

Attach the 4 clips to install the engine cover.