Engine unit 2AD-FHV

Replacement

-

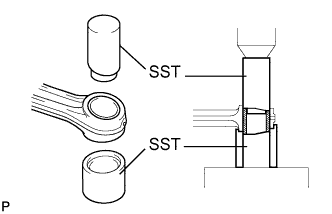

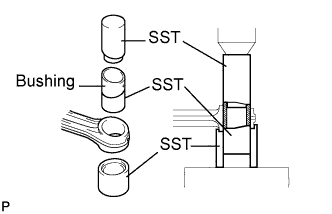

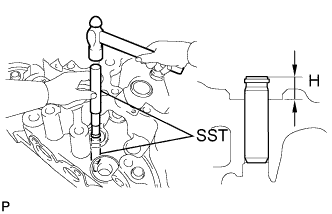

Using SST and a press, push out the bush.

SST:

09222-54011 (09222-03016, 09222-03026)

-

Using a round file, lightly file off any roughness from the small end of the connecting rod.

-

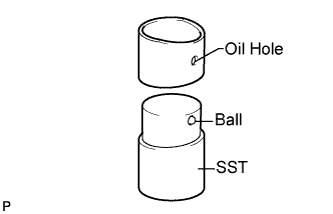

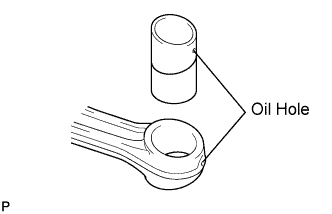

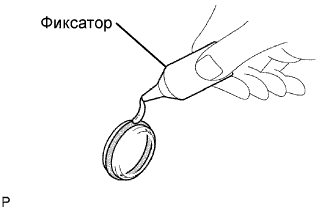

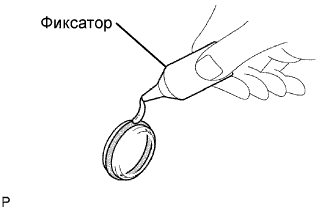

Attach a new bush to SST with the ball of SST inside the oil hole of the bush.

SST:

09222-54011 (09222-03021)

-

Align the oil holes of the bush and connecting rod.

-

Using SST and a press, push in the bush.

SST:

09222-54011 (09222-03016, 09222-03026, 09222-03021)

-

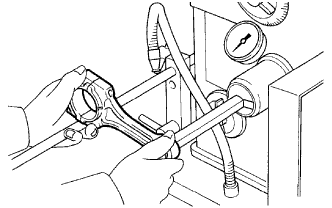

Using a pin hole grinder, hone the bush to obtain the standard specified clearance between the bush and piston pin.

-

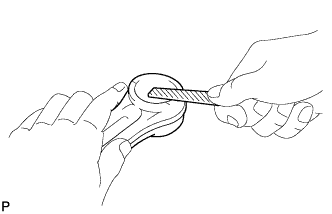

Check that the piston pin fits at normal room temperature.

-

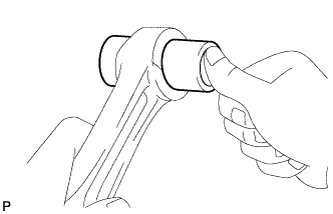

Coat the piston pin with engine oil, and push it into the connecting rod with your thumb.

-

-

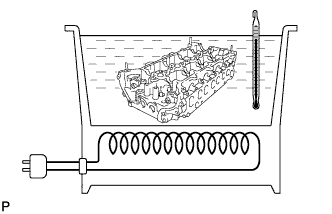

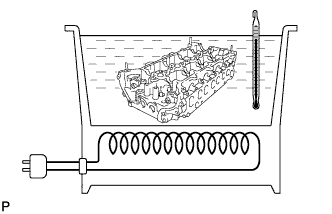

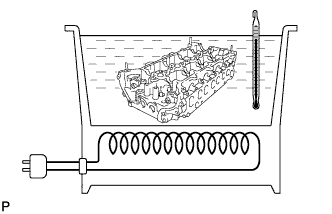

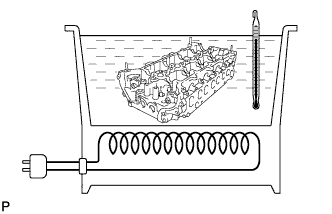

Gradually heat the cylinder head to approximately 80 to 100°C (176 to 212°F).

-

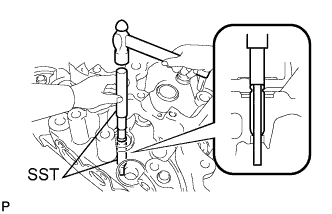

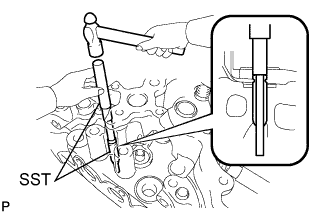

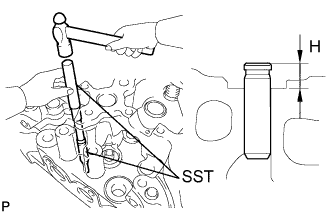

Using SST and a hammer, tap out the valve guide bush.

SST:

09201-10000 09950-70010

-

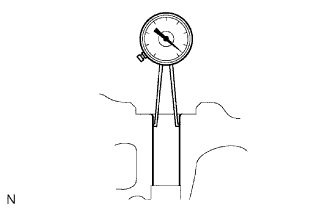

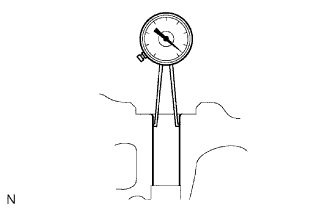

Using a caliper gauge, measure the bush bore diameter of the cylinder head.

-

Select a new guide bush (STD or O/S 0.05).

Bush bore diameter:

Bush size Specified Condition Use STD 10.985 to 11.006 mm (0.4324 to 0.4333 in.) Use O/S 0.05 11.056 to 11.065 mm (0.4353 to 0.4356 in.) HINT:

- If the bush bore diameter of the cylinder head is greater than 11.006 mm (0.4333 in.), machine the bush bore diameter to between 11.056 and 11.065 mm (0.4353 to 0.4356 in.).

- If the bush bore diameter of the cylinder head is greater than 11.065 mm (0.4356 in.), replace the cylinder head.

-

Gradually heat the cylinder head to approximately 80 to 100°C (176 to 212°F).

-

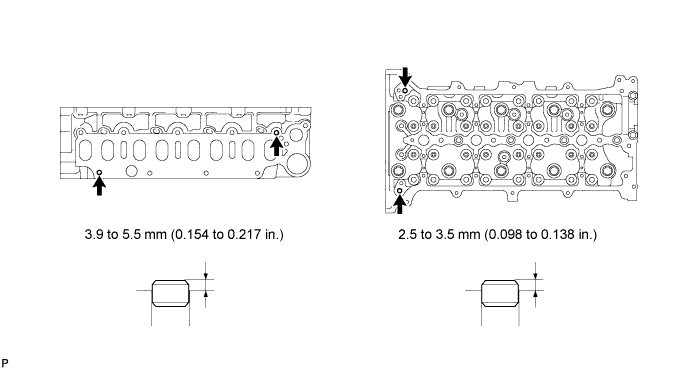

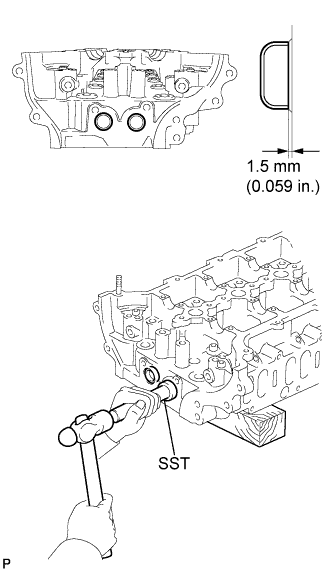

Using SST and a hammer, tap in a new guide bush to the specified protrusion height.

SST:

09201-10000 09950-70010

Standard protrusion height (H):

9.0 to 9.4 mm (0.354 to 0.370 in.)

-

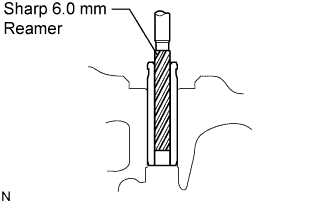

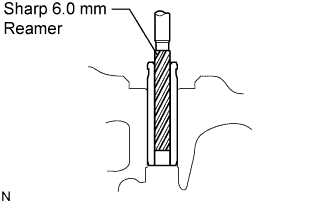

Using a sharp 6.0 mm reamer, ream the guide bush to obtain the standard specified clearance between the guide bush and valve stem.

-

Gradually heat the cylinder head to approximately 80 to 100°C (176 to 212°F).

-

Using SST and a hammer, tap out the valve guide bush.

SST:

09201-10000 09950-70010

-

Using a caliper gauge, measure the bush bore diameter of the cylinder head.

-

Select a new guide bush (STD or O/S 0.05).

Standard bush bore diameter:

Bush Size Specified Condition Use STD 11.006 to 11.015 mm (0.4333 to 0.4337 in.) Use O/S 0.05 11.056 to 11.065 mm (0.4353 to 0.4356 in.) HINT:

- If the bush bore diameter of the cylinder head is greater than 11.015 mm (0.4337 in.), machine the bush bore diameter to between 11.056 and 11.065 mm (0.4353 to 0.4356 in.).

- If the bush bore diameter of the cylinder head is greater than 11.065 mm (0.4356 in.), replace the cylinder head.

-

Gradually heat the cylinder head to approximately 80 to 100°C (176 to 212°F).

-

Using SST and a hammer, tap in a new guide bush to the specified protrusion height.

SST:

09201-10000 09950-70010

Standard protrusion height (H):

10.3 to 10.7 mm (0.406 to 0.421 in.)

-

Using a sharp 6.0 mm reamer, ream the guide bush to obtain the standard specified clearance between the guide bush and valve stem.

NOTICE:

If water leaks from the tight plug or the plug corrodes, replace it.

-

Remove the tight plugs.

-

Apply adhesive around the tight plug.

Adhesive:

Toyota genuine adhesive 1324, three bond 1324 or equivalent

-

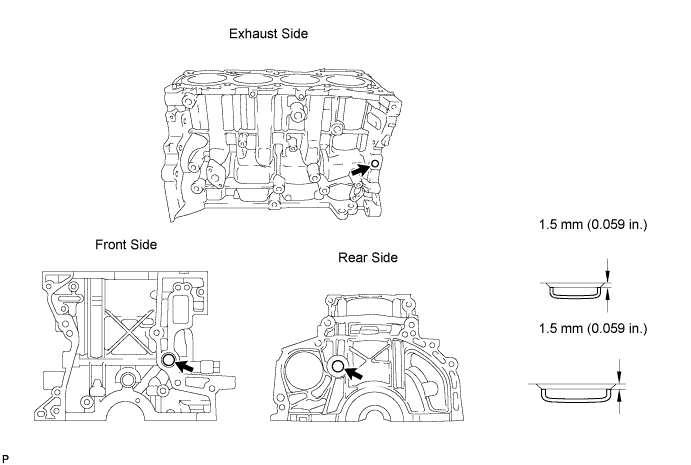

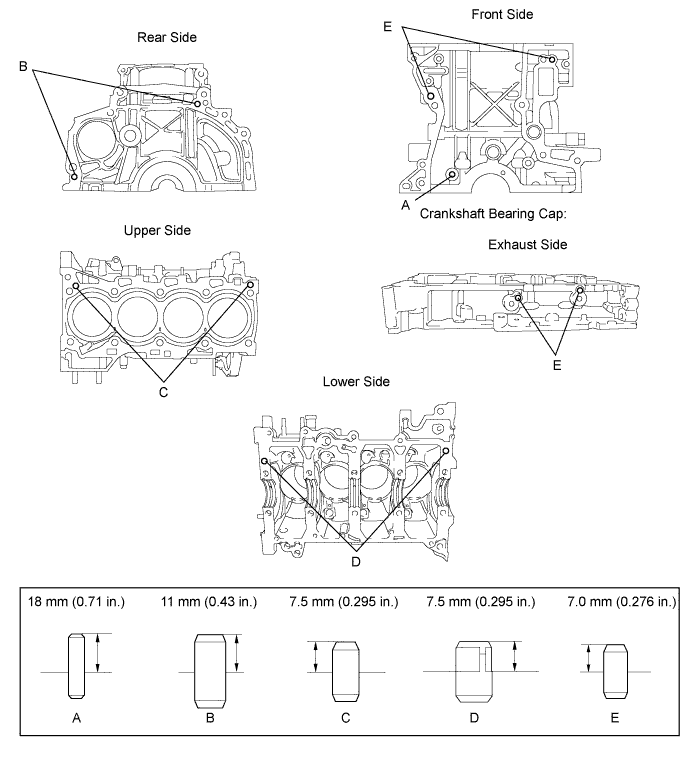

Using SST and a hammer, tap in 3 new tight plugs shown in the illustration.

SST:

09950-60010 09950-70010

NOTICE:

If the stud bolt is deformed or the threads are damaged, replace it.

-

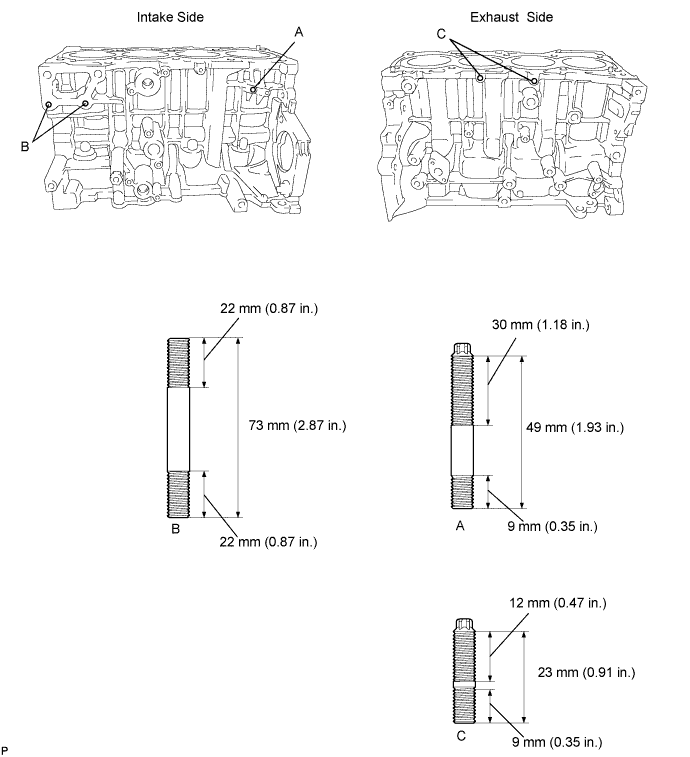

Remove the stud bolts.

-

Using an E5 "torx" socket wrench, install stud bolts A and C.

Torque:

3.0 N*m{ 31 kgf*cm , 27 lbsf.in } for bolt A

2.0 N*m{ 20 kgf*cm , 18 lbsf.in } for bolt C

-

Apply adhesive to the hole for stud bolt B on the cylinder block. Install stud bolts B.

Torque:

20 N*m{ 204 kgf*cm , 15 ft.*lbf }

-

Apply adhesive to the hole for the stud bolt on the cylinder block. Install the 2 stud bolts to the crankshaft bearing cap.

Torque:

5.0 N*m{ 51 kgf*cm , 44 lbsf.in }

NOTICE:

It is not necessary to remove with straight pin unless it is being replaced.

-

Remove the straight pin.

-

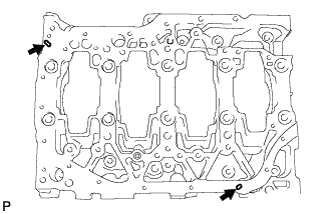

Using a plastic-faced hammer, tap in new straight pins to the cylinder block.

-

Using a plastic-faced hammer, tap in new ring pins to the crankshaft bearing cap.

NOTICE:

It is not necessary to remove the ring pin unless it is being replaced.

-

Remove the ring pins.

-

Using a plastic-faced hammer, tap in a new ring pin until the pin stops.

NOTICE:

If water leaks from the tight plug or the plug corrodes, replace it.

-

Remove the tight plugs.

-

Apply adhesive to the tight plug hole of the cylinder head.

Adhesive:

Toyota genuine adhesive 1324, three bond 1324 or equivalent

-

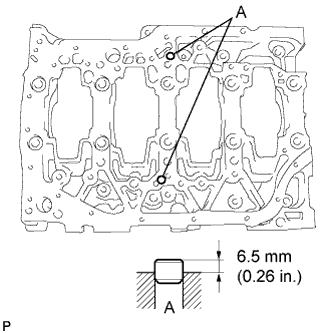

Using SST, tap in a new tight plug to the cylinder head as shown in the illustration.

SST:

09950-60010 09950-70010

NOTICE:

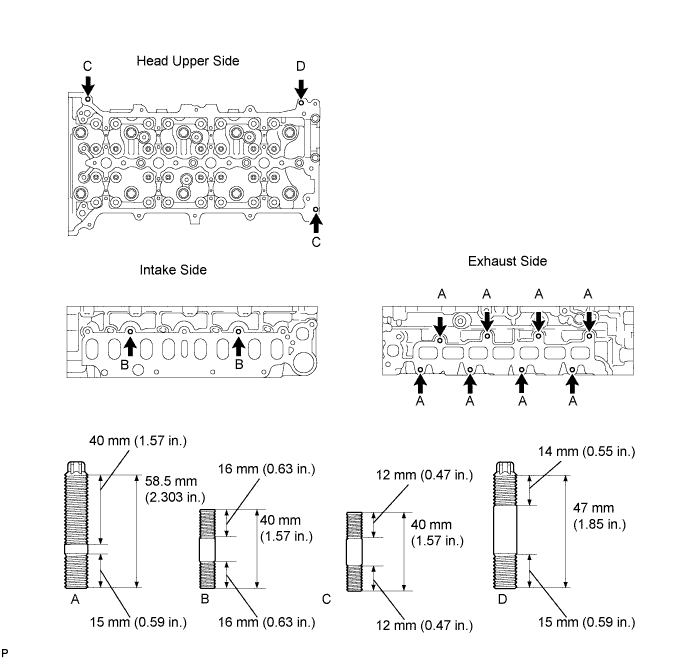

If the stud bolt is deformed or the threads are damaged, replace it.

-

Remove the stud bolts.

-

Using an E8 "torx" socket wrench, install the stud bolts.

Torque:

12 N*m{ 122 kgf*cm , 9 ft.*lbf } for stud bolt A and B

5.0 N*m{ 51 kgf*cm , 44 lbsf.in } for stud bolt C

8.0 N*m{ 82 kgf*cm , 71 lbsf.in } for stud bolt D