Components Crankshaft position sensor 2AD-FHV

Removal Crankshaft position sensor 2AD-FHV

Inspection Crankshaft position sensor 2AD-FHV

Installation Crankshaft position sensor 2AD-FHV

Crankshaft position sensor 2AD-FHV

Components

Crankshaft position sensor 2AD-FHV Components

Removal

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

-

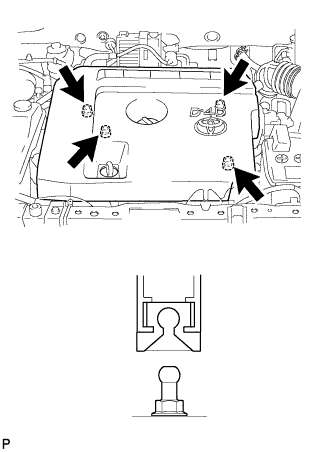

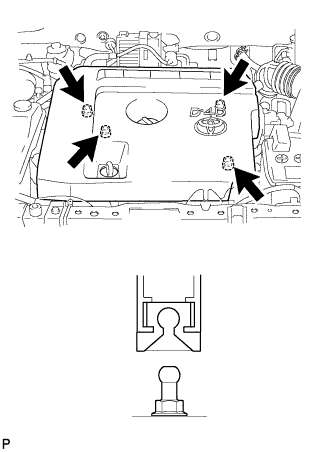

Detach the 4 clips and remove the engine cover.

-

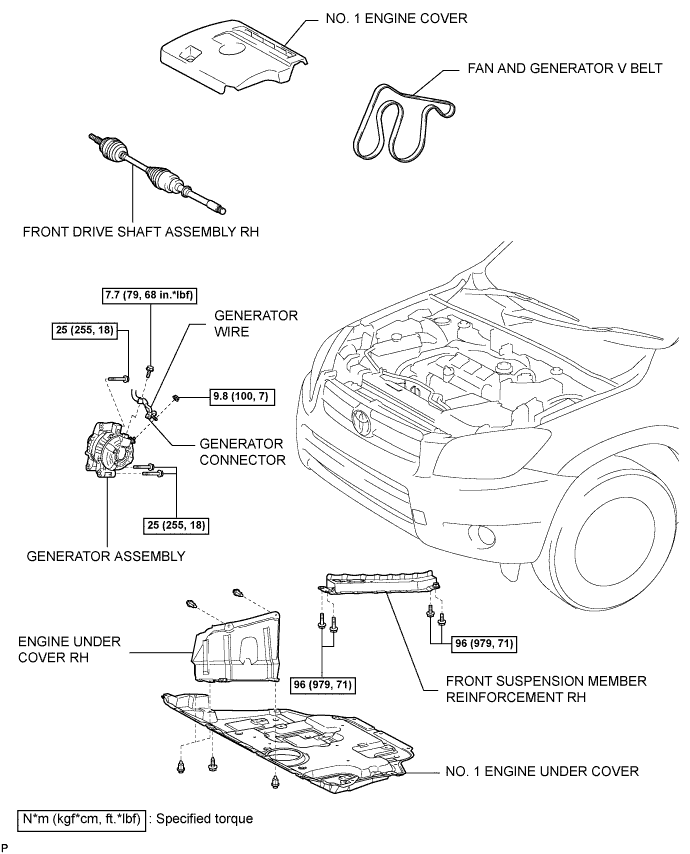

Remove the 4 bolts, 12 clips and engine under cover.

-

Remove the 2 clips and engine under cover.

-

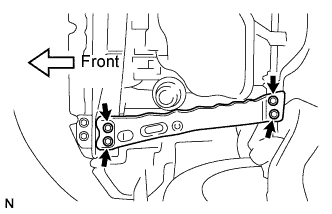

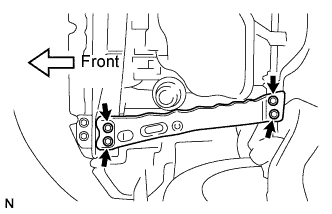

Remove the 4 bolts and reinforcement.

-

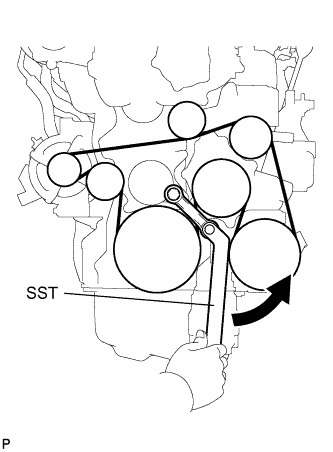

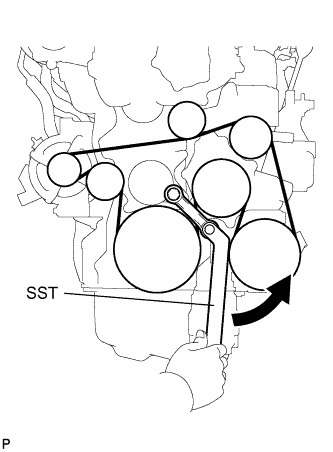

Using SST and 22 mm wrench, rotate the tensioner pulley counterclockwise to loosen the belt tension. Then remove the V-ribbed belt.

SST:

09216-42010

NOTICE:

Make sure SST is installed as shown in the illustration. If not, SST and/or the V-ribbed belt may not be able to be removed.

-

Remove the front drive shaft.

-

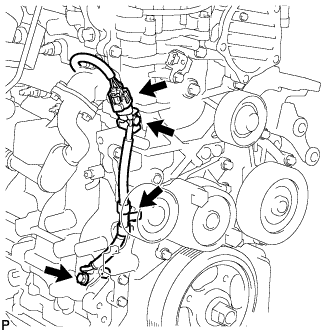

Disconnect the generator connector.

-

Remove the terminal cap.

-

Remove the nut and bolt, and disconnect the generator wire.

-

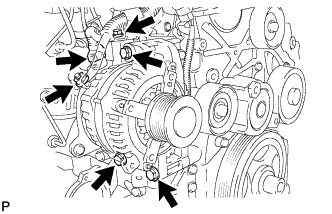

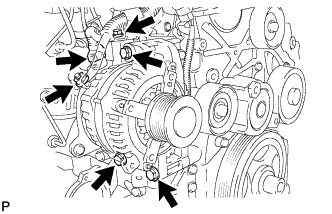

Remove the 3 bolts and generator.

-

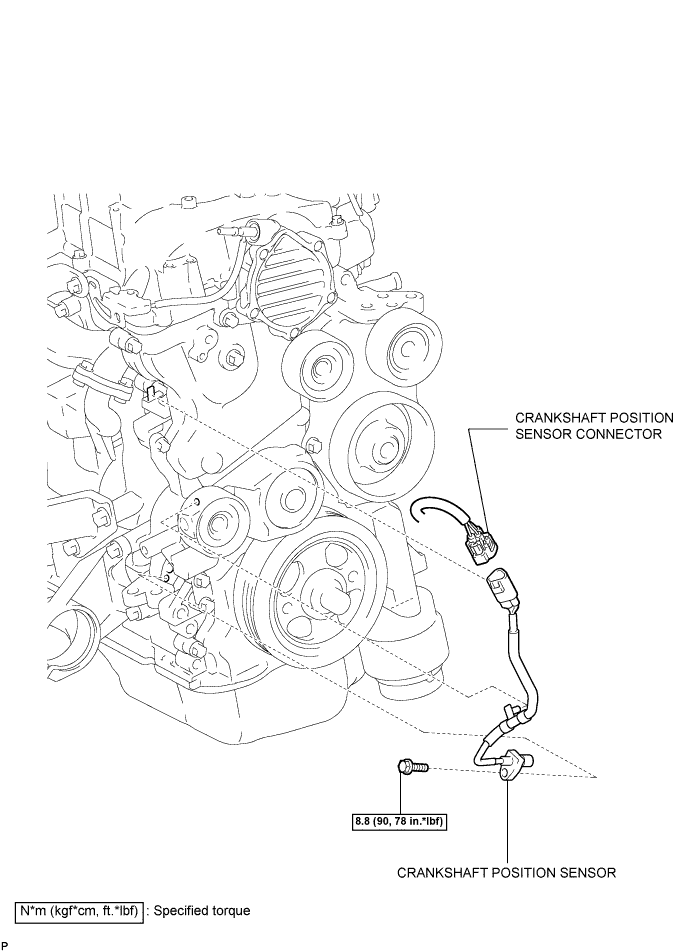

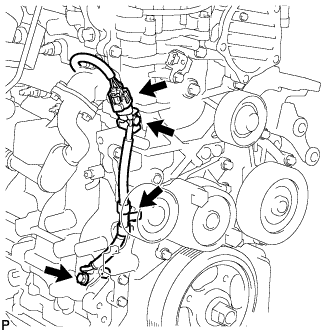

Disconnect the sensor connector.

-

Disconnect the sensor connector from the bracket.

-

Disconnect the sensor wire harness clamp.

-

Remove the bolt and sensor.

Crankshaft position sensor 2AD-FHV

Inspection

-

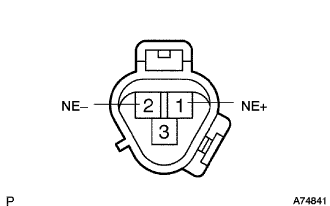

Measure the resistance between the terminals.

Standard resistance:

Temperature Specified Condition Cold 835 to 1,400 ? Hot 1,060 to 1,645 ? NOTICE:

In the table above, the terms "Cold" and "Hot" refer to the temperature of the coils. "Cold" means approximately -10 to 50°C (14 to 122°F). "Hot" means approximately 50 to 100°C (122 to 212°F).

If the resistance is not as specified, replace the sensor.

Crankshaft position sensor 2AD-FHV

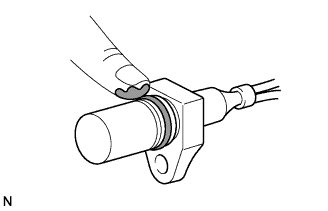

Installation

-

Apply a light coat of engine oil to the O-ring of the sensor.

-

Install the sensor with the bolt.

Torque:

8.8 Н*м{ 90 кгс*см , 78 фунт-сила-дюймов }

-

Connect the sensor wire harness clamp.

-

Connect the sensor connector to the bracket.

-

Connect the sensor connector.

-

Install the generator with the 3 bolts.

Момент затяжки:

25 Н*м{ 255 кгс*см , 18 фунт-сила-футов }

NOTICE:

Be careful that the wire harness of the crankshaft position sensor does not get caught between the cylinder block and generator when installing the generator.

-

Connect the generator wire with the nut and bolt.

Torque:

9.8 Н*м{ 100 кгс*см , 87 фунт-сила-дюймов } for nut

7.7 Н*м{ 79 кгс*см , 68 фунт-сила-дюймов } for bolt

-

Install the terminal cap.

-

Connect the generator connector.

-

Install the front drive shaft.

-

Using SST and 22 mm wrench, rotate the tensioner pulley counterclockwise, and then install the V-ribbed belt.

SST:

09216-42010

NOTICE:

- Make sure that the V-ribbed belt is set properly at each pulley.

- Make sure SST is installed as shown in the illustration. If not, SST and/or the V-ribbed belt may not be able to be removed.

-

Install the reinforcement with the 4 bolts.

Torque:

95 Н*м{ 969 кгс*см , 70 фунт-сила-футов }

-

Install the engine under cover with the 2 clips.

-

Install the engine under cover with the 12 clips and 4 bolts.

-

Attach the 4 clips to install the engine cover.