Common rail 2AD-FHV

Components

Common rail 2AD-FHV

Removal

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

-

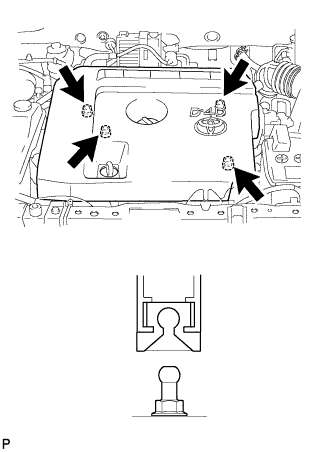

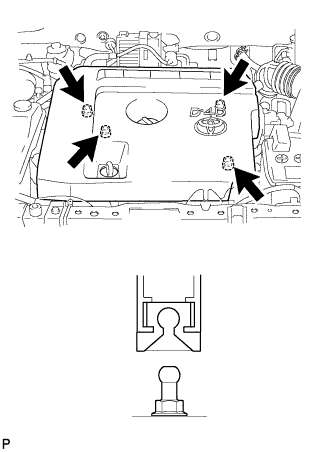

Detach the 4 clips and remove the engine cover.

-

Disconnect the fuel pressure sensor connector.

-

Disconnect the pressure discharge valve connector.

-

Disconnect the turbo pressure sensor connector.

-

Remove the grommet and nut and disconnect the glow plug wire harness.

-

Remove the 2 nuts and disconnect the engine wire from the engine cover bracket.

NOTICE:

After removing the fuel inlet pipe, cover the common rail and injection or supply pump with electrical tape to prevent dirt from entering them.

-

Remove the nut and fuel inlet pipe clamps.

-

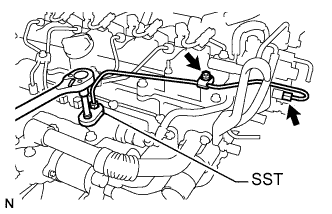

Using SST, remove the fuel inlet pipe.

SST:

09023-38401

NOTICE:

After removing the injection pipe, cover the common rail and injector with electrical tape to prevent dust from entering them.

-

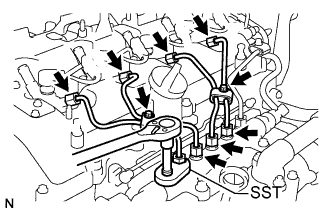

Remove the 2 bolts and 4 injection pipe clamps.

-

Using SST, loosen the 4 nuts at the common rail end of the injection pipes.

SST:

09023-38401

-

Using SST, loosen the 4 nuts at the injector end of the injection pipes.

SST:

09023-38401

-

Remove the 4 injection pipes.

-

Using pliers, grip the claws of the clip and slide the clip to disconnect the pressure fuel hose.

-

Remove the 2 bolts, common rail and intake manifold insulator.

Common rail 2AD-FHV

Inspection

-

Inspect the fuel pressure sensor.

-

Measure the resistance of the sensor.

HINT:

Perform the inspection with no fuel pressure applied.

Standard resistance:

If the result is not as specified, replace the common rail assembly.Tester Connection Specified Condition 5 (PR) - 4 (E2) 16.4 k? or less 2 (PR2) - 3 (E2S) 16.4 k? or less 6 (VC) - 5 (PR) 3 k? or less 1 (VCS) - 2 (PR2) 3 k? or less

-

-

Inspect the pressure discharge valve.

-

Measure the resistance of the valve.

Standard resistance:

Tester Connection Condition Specified Condition 1 - 2 20°C (68°F) 0.85 to 1.05 ? HINT:

The temperature indicated in "Condition" is the temperature of the pressure discharge valve.

If the result is not as specified, replace the common rail assembly.

-

Common rail 2AD-FHV

Installation

-

Install the intake manifold insulator and common rail with the 2 bolts.

Torque:

20.5 N*m{ 209 kgf*cm , 15 ft.*lbf }

-

Using pliers, grip the claws of the clip and slide the clip to connect the fuel hose as shown in the illustration.

NOTICE:

In a case where the common rail is replaced, the injection pipes must also be replaced.

-

Temporarily install the 4 injection pipes.

-

Using SST, tighten the 4 nuts at the common rail end of the injection pipes.

SST:

09023-38401

Torque:

27 N*m{ 275 kgf*cm , 20 ft.*lbf }

HINT:

- Use of the proper SST is required to ensure that the correct torque is applied to the injection pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation. If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new pipe.

-

Using SST, tighten the 4 nuts at the injector end of the injection pipes.

SST:

09023-38401

Torque:

27 N*m{ 275 kgf*cm , 20 ft.*lbf }

HINT:

- Use of the proper SST is required to ensure that the correct torque is applied to the injection pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation. If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new pipe.

NOTICE:

- In a case where the common rail is replaced, the fuel inlet pipe must also be replaced.

-

Temporarily install the fuel inlet pipe with the 2 clamps and nut.

-

Using SST, tighten the nut at the common rail end of the fuel inlet pipe.

SST:

09023-38401

Torque:

27 N*m{ 275 kgf*cm , 15 ft.*lbf }

HINT:

- Use of the proper SST is required to ensure that the correct torque is applied to the inlet pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation. If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new pipe.

-

Using SST, tighten the nut at the supply pump end of the fuel inlet pipe.

SST:

09023-38401

Torque:

27 N*m{ 275 kgf*cm , 20 ft.*lbf }

HINT:

- Use of the proper SST is required to ensure that the correct torque is applied to the inlet pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation. If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new pipe.

-

Tighten the fuel inlet pipe clamp nut.

Torque:

5.0 N*m{ 51 kgf*cm , 44 lbsf.in }

-

Connect the engine wire to the engine cover bracket.

-

Connect the glow plug wire harness.

-

Install the 2 nuts.

-

Install the nut and grommet.

Torque:

2.2 N*m{ 22 kgf*cm , 19 lbsf.in }

-

Connect the turbo pressure sensor connector.

-

Connect the pressure discharge valve connector.

-

Connect the fuel pressure sensor.

-

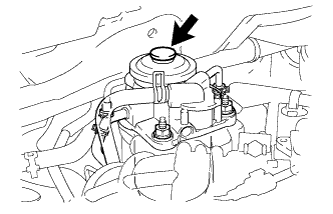

Using the hand pump indicated by the arrows in the illustration, bleed the fuel system. Continue pumping until pumping becomes difficult.

-

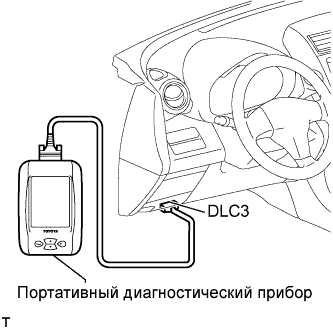

Perform the ACTIVE TEST.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch on (IG).

-

Turn the intelligent tester ON.

-

Enter the following menus: Powertrain / Engine / Active Test.

-

Perform the Active Test.

Intelligent Tester Display Test Details Control Range Diagnostic Notes Test the Fuel Leak Pressurizing common rail internal fuel pressure, and checking for fuel leaks Stop/Start - Fuel pressure inside common rail pressurized to specified value and engine speed increased to 2,000 rpm when Start is selected

- Above conditions to be maintained while test is Start

-

-

Attach the 4 clips to install the engine cover.