TYPICAL MALFUNCTION THRESHOLDS

READ VALUE USING TECHSTREAM (+BM VOLTAGE)

CHECK HARNESS AND CONNECTOR (ECM - ETCS FUSE, ETCS FUSE - BATTERY)

INSPECT ECM (+BM TERMINAL VOLTAGE)

DTC P2118 Throttle Actuator Control Motor Current Range / Performance |

DESCRIPTION

The ETCS (Electronic Throttle Control System) has a dedicated power supply circuit. The voltage (+BM) is monitored and when it is low (less than 4 V), the ECM determines that there is a malfunction in the ETCS and cuts off the current to the throttle actuator.When the voltage becomes unstable, the ETCS itself becomes unstable. For this reason, when the voltage is low, the current to the throttle actuator is cut. If repairs are made and the system returns to normal, turn the ignition switch off. The ECM then allows the current to flow to the throttle actuator so that it can be restarted.

- HINT:

- The ETCS does not use a throttle cable.

| DTC No. | DTC Detection Condition | Trouble Area |

| P2118 | Open in ETCS (Electronic Throttle Control System) power source (+BM) circuit (1 trip detection logic) |

|

MONITOR DESCRIPTION

The ECM monitors the battery supply voltage applied to the throttle actuator.When the power supply voltage (+BM) drops below 4 V for 0.8 seconds or more, the ECM interprets this as an open in the power supply circuit (+BM). The ECM illuminates the MIL and stores the DTC.

If the malfunction is not repaired successfully, the DTC is stored 5 seconds after the engine is next started.

MONITOR STRATEGY

| Related DTCs | P2118: Throttle actuator power supply |

| Required Sensors/Components (Main) | Throttle actuator, throttle valve, ETCS fuse |

| Required Sensors/Components (Related) | None |

| Frequency of Operation | Continuous |

| Duration | 0.8 seconds |

| MIL Operation | Immediate |

| Sequence of Operation | None |

TYPICAL ENABLING CONDITIONS

| Monitor runs whenever following DTCs not present | None |

| Battery voltage | 8 V or more |

| Electronic throttle actuator power | ON |

TYPICAL MALFUNCTION THRESHOLDS

| Throttle actuator power supply voltage (+BM) | Less than 4 V |

COMPONENT OPERATING RANGE

| Throttle actuator power supply voltage (+BM) | 11 to 14 V |

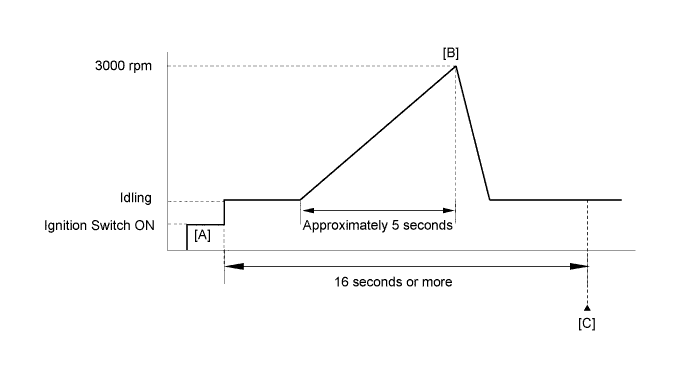

CONFIRMATION DRIVING PATTERN

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON and turn the Techstream on.

- Clear DTCs (even if no DTCs are stored, perform the clear DTC operation).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON and turn the Techstream on [A].

- Start the engine.

- Slowly depress the accelerator pedal, raise the engine speed to approximately 3000 rpm over approximately 5 seconds, and then idle the engine [B].

- Check that 16 seconds or more have elapsed since the engine was started.

- Enter the following menus: Powertrain / Engine and ECT / Trouble Codes [C].

- Read pending DTCs.

- HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

- Input the DTC: P2118.

- Check the DTC judgment result.

Techstream Display Description NORMAL - DTC judgment completed

- System normal

ABNORMAL - DTC judgment completed

- System abnormal

INCOMPLETE - DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A - Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

- HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform steps [B] through [C] again.

- DTC judgment completed

- If no pending DTC is output, perform a universal trip and check for permanent DTCs (YARIS_NCP93 RM000000PDK0QGX.html).

- HINT:

- If a permanent DTC is output, the system is malfunctioning.

- If no permanent DTC is output, the system is normal.

FAIL-SAFE

When this DTC, or other DTCs relating to ETCS (Electronic Throttle Control System) malfunctions, are stored, the ECM enters fail-safe mode. During fail-safe mode, the ECM cuts off the current to the throttle actuator, and the throttle valve is returned to a 6° throttle angle by the return spring. The ECM then adjusts the engine output by controlling the fuel injection (intermittent fuel cut) and ignition timing, in accordance with the accelerator pedal opening angle, to allow the vehicle to continue at a minimal speed. If the accelerator pedal is depressed firmly and gently, the vehicle can be driven slowly.Fail-safe mode continues until a pass condition is detected, and the ignition switch is then turned to OFF.

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

- After turning ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work (YARIS_NCP93 RM000000UYX0BYX.html).

- HINT:

- Read freeze frame data using the Techstream. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.READ VALUE USING TECHSTREAM (+BM VOLTAGE) |

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Enter the following menus: Powertrain / Engine and ECT / Data List / +BM Voltage.

Read the value displayed on the Techstream.

- Standard voltage:

- 11 to 14 V

|

| ||||

| OK | ||

| ||

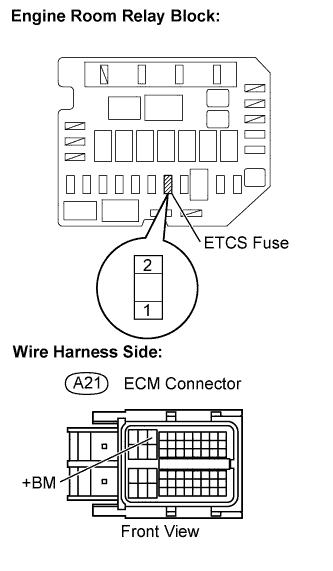

| 2.CHECK HARNESS AND CONNECTOR (ECM - ETCS FUSE, ETCS FUSE - BATTERY) |

|

Check the harness and connector between the ETCS fuse and ECM.

Remove the ETCS fuse from the engine room relay block.

Disconnect the A21 ECM connector.

Check the resistance.

- Standard resistance (Check for open):

Tester Connections Specified Conditions ETCS fuse (2) - +BM (A21-3) Below 1 Ω

- Standard resistance (Check for short):

Tester Connections Specified Conditions ETCS fuse (2) or +BM (A21-3) - Body ground 10 kΩ or higher

Reinstall the ETCS fuse.

Reconnect the ECM connector.

Check the harness and connector between the ETCS fuse and positive battery cable.

Remove the ETCS fuse from the engine room relay block.

Disconnect the cable from the negative battery terminal.

Disconnect the cable from the positive battery terminal.

Check the resistance.

- Standard resistance (Check for open):

Tester Connections Specified Conditions Positive battery cable - ETCS fuse (1) Below 1 Ω

- Standard resistance (Check for short):

Tester Connections Specified Conditions Positive battery cable or ETCS fuse (1) - Body ground 10 kΩ or higher

Reinstall the ETCS fuse.

Reconnect the cable to the positive battery terminal.

Reconnect the cable to the negative battery terminal.

|

| ||||

| OK | |

| 3.INSPECT ECM (+BM TERMINAL VOLTAGE) |

|

Disconnect the A21 and C20 ECM connectors.

Measure the voltage between the terminals of the A21 and C20 ECM connectors.

- Standard voltage:

Tester Connections Specified Conditions +BM (A21-3) - E1 (C20-104) 11 to 14 V +BM (A21-3) - ME01 (C20-43) 11 to 14 V

Reconnect the ECM connectors.

|

| ||||

| OK | ||

| ||