DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING GTS (ACTIVATE THE VSV FOR SWIRL CONTROL VALVE)

INSPECT NO. 1 VACUUM SWITCHING VALVE FOR SWIRL CONTROL VALVE (RESISTANCE)

INSPECT NO. 1 VACUUM SWITCHING VALVE (FOR SWIRL CONTROL VALVE) (POWER SOURCE VOLTAGE)

CHECK HARNESS AND CONNECTOR (NO. 1 VACUUM SWITCHING VALVE (FOR SWIRL CONTROL VALVE) - ECM)

REPLACE ECM

CHECK HARNESS AND CONNECTOR (NO. 1 VACUUM SWITCHING VALVE (FOR SWIRL CONTROL VALVE) - NO. 1 INTEGRATION RELAY)

INSPECT ECM POWER SOURCE CIRCUIT

REPLACE VACUUM CONTROL VALVE SET

REPAIR OR REPLACE HARNESS OR CONNECTOR

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P2009 Intake Manifold Runner Control Circuit Low (Bank 1) |

DTC P2010 Intake Manifold Runner Control Circuit High (Bank 1) |

DESCRIPTION

Refer to DTC P2006 (HILUX_TGN26 RM000000YGW044X_01.html).P2009DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

2 seconds after engine is started, race engine for 1 second

| Open in No. 1 vacuum switching valve (for swirl control valve) circuit for 0.5 seconds (2 trip detection logic).

| - No. 1 vacuum switching valve (for swirl control valve)

- Open in No. 1 vacuum switching valve (for swirl control valve) circuit

- ECM

|

P2010DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

2 seconds after engine is started, race engine for 1 second

| Short in No. 1 vacuum switching valve (for swirl control valve) circuit for 0.5 seconds (2 trip detection logic).

| - No. 1 vacuum switching valve (for swirl control valve)

- Short in No. 1 vacuum switching valve (for swirl control valve) circuit

- ECM

|

WIRING DIAGRAM

Refer to DTC P2006 (HILUX_TGN26 RM000000YGW044X_02.html).

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses of circuits related to this system before performing the following inspection procedure.

- After replacing the ECM, the new ECM needs registration (HILUX_TGN26 RM0000012XK05AX.html) and initialization (HILUX_TGN26 RM000000TIN058X.html).

- HINT:

- Read freeze frame data using the GTS. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.PERFORM ACTIVE TEST USING GTS (ACTIVATE THE VSV FOR SWIRL CONTROL VALVE) |

Connect the GTS to the DLC3.

Disconnect the vacuum hoses from the No. 1 vacuum switching valve (for swirl control valve).

Turn the ignition switch to ON and turn the GTS on.

Enter the following menus: Powertrain / Engine / Active Test / Activate the VSV for Swirl Control Valve.

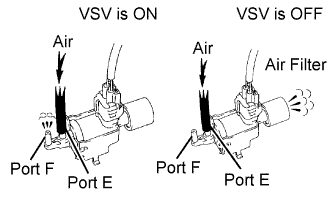

Check the VSV operation when it is operated using the GTS.

- OK:

Tester Operation

| Specified Condition

|

VSV ON

| Air from port E flows out through port F

|

VSV OFF

| Air from port E flows out through air filter

|

Reconnect the vacuum hoses.

| 2.INSPECT NO. 1 VACUUM SWITCHING VALVE FOR SWIRL CONTROL VALVE (RESISTANCE) |

Inspect the No. 1 vacuum switching valve (for swirl control valve) (HILUX_TGN26 RM0000053UN004X_01_0001.html).

| 3.INSPECT NO. 1 VACUUM SWITCHING VALVE (FOR SWIRL CONTROL VALVE) (POWER SOURCE VOLTAGE) |

Disconnect the No. 1 vacuum switching valve (for swirl control valve) connector.

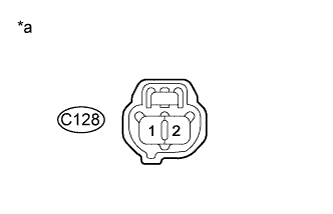

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

C128-2 - Body ground

| Ignition switch ON

| 11 to 14 V

|

Text in Illustration*a

| Front view of wire harness connector

(to Vacuum Switching Valve (for No. 1 Swirl Control Valve))

|

Reconnect the No. 1 vacuum switching valve (for swirl control valve) connector.

| 4.CHECK HARNESS AND CONNECTOR (NO. 1 VACUUM SWITCHING VALVE (FOR SWIRL CONTROL VALVE) - ECM) |

Disconnect the No. 1 vacuum switching valve (for swirl control valve) connector.

Disconnect the ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C128-1 - C164-7 (SCV)

| Always

| Below 1 Ω

|

C128-1 or C164-7 (SCV) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the No. 1 vacuum switching valve (for swirl control valve) connector.

Reconnect the ECM connector.

Replace the ECM (HILUX_TGN26 RM0000013Z001IX.html).

| 6.CHECK HARNESS AND CONNECTOR (NO. 1 VACUUM SWITCHING VALVE (FOR SWIRL CONTROL VALVE) - NO. 1 INTEGRATION RELAY) |

Remove the No. 1 integration relay from the engine room relay block and junction block assembly.

Disconnect the No. 1 integration relay connector.

Disconnect the No. 1 vacuum switching valve (for swirl control valve) connector.

Measure the resistance of the wire harness side connectors.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

1J-5 - C128-2

| Always

| Below 1 Ω

|

1J-5 or C128-2 - Body ground

| Always

| 10 kΩ or higher

|

Reinstall the No. 1 integration relay.

Reconnect the No. 1 integration relay connector.

Reconnect the No. 1 vacuum switching valve (for swirl control valve) connector.

| 7.INSPECT ECM POWER SOURCE CIRCUIT |

Check the ECM power source circuit (HILUX_TGN26 RM000000TI2076X.html).

| 8.REPLACE VACUUM CONTROL VALVE SET |

Replace the vacuum control valve set (HILUX_TGN26 RM0000044GF00OX_01_0064.html).

| 9.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Repair or replace harness or connector.

| 10.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the GTS to the DLC3.

Clear the DTCs (HILUX_TGN26 RM000000PDK12TX.html).

Start the engine and wait for 3 seconds or more.

2 seconds after the engine is started, race the engine for 1 second.

Enter the following menus: Powertrain / Engine / Trouble Codes.

Confirm that the DTC is not output again.