Engine Unit (W/ Glow Plug Controller) -- Installation |

- NOTICE:

- When replacing the injectors (including shuffling the injectors between the cylinders), common rail or cylinder head, it is necessary to replace the injection pipes with new ones.

- When replacing the fuel supply pump, common rail, cylinder block, cylinder head, cylinder head gasket or timing gear case, it is necessary to replace the fuel inlet pipe with a new one.

- After removing the injection pipes, clean them with a brush and compressed air.

| 1. INSTALL FRONT NO. 1 ENGINE MOUNTING BRACKET LH |

Install the front No. 1 engine mounting bracket with the 4 bolts.

- Torque:

- 68 N*m{693 kgf*cm, 50 ft.*lbf}

| 2. INSTALL FRONT NO. 1 ENGINE MOUNTING BRACKET RH |

Install the front No. 1 engine mounting bracket with the 4 bolts.

- Torque:

- 68 N*m{693 kgf*cm, 50 ft.*lbf}

| 3. INSTALL ENGINE COOLANT TEMPERATURE SENSOR |

Install a new gasket to the engine coolant temperature sensor.

Install the engine coolant temperature sensor.

- Torque:

- 20 N*m{200 kgf*cm, 14 ft.*lbf}

Connect the engine coolant temperature sensor connector.

| 4. INSTALL CAMSHAFT POSITION SENSOR |

Apply a light coat of engine oil to the O-ring of the camshaft position sensor.

Install the camshaft position sensor with the bolt.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

Connect the camshaft position sensor connector.

| 5. INSTALL CRANKSHAFT POSITION SENSOR |

Apply a light coat of engine oil to the O-ring of the crankshaft position sensor.

Install the crankshaft position sensor with the bolt.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

Attach the 4 clips and connect the crankshaft position sensor connector.

- NOTICE:

- Insert the crankshaft position sensor wire harness into the protrusions of the timing gear cover.

| 6. INSTALL VANE PUMP ASSEMBLY |

Install a new O-ring to the vane pump.

Install the vane pump with the 2 nuts.

- Torque:

- 41 N*m{418 kgf*cm, 30 ft.*lbf}

| 7. INSTALL VACUUM PUMP ASSEMBLY |

Install 2 new O-rings to the vacuum pump.

Install the vacuum pump with the 2 nuts.

- Torque:

- 21 N*m{210 kgf*cm, 15 ft.*lbf}

| 8. INSTALL OIL COOLER COVER SUB-ASSEMBLY |

Install a new gasket and the oil cooler cover with the 13 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Connect the No. 2 vacuum transmitting pipe with the 2 nuts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Connect the oil pressure switch connector.

| 9. INSTALL FUEL SUPPLY PUMP ASSEMBLY |

| 10. INSTALL COMMON RAIL ASSEMBLY |

| 11. INSTALL OIL FILTER SUB-ASSEMBLY |

Check and clean the oil filter installation surface.

Apply clean engine oil to the gasket of a new oil filter.

Lightly screw the oil filter into place by hand. Tighten it until the gasket contacts the seat.

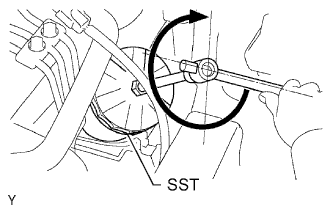

Using SST, tighten the oil filter. Depending on the space available, choose from the following.

- SST

- 09228-07501

If enough space is available, use a torque wrench to tighten the oil filter.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

If enough space is not available to use a torque wrench, tighten the oil filter 3/4 of a turn by hand or with a common wrench.

|

| 12. INSTALL NO. 2 CYLINDER HEAD COVER SUB-ASSEMBLY |

Install the No. 2 cylinder head cover with the 3 bolts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 13. INSTALL WIRING HARNESS CLAMP BRACKET |

Install the 2 wiring harness clamp brackets with the 3 bolts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Attach the 6 wire harness clamps.

| 14. INSTALL FUEL HOSE BRACKET (for DPF) |

Install the fuel hose bracket with the bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

| 15. INSTALL NO. 1 FUEL PIPE (for DPF) |

Install the No. 1 fuel pipe.

| 16. INSTALL FUEL HOSE PROTECTOR (for DPF) |

Install the fuel hose protector with the bolt and nut.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 17. INSTALL GLOW PLUG ASSEMBLY |

| 18. INSTALL INTAKE MANIFOLD |

| 19. INSTALL ELECTRIC EGR CONTROL VALVE ASSEMBLY |

| 20. INSTALL DIESEL THROTTLE BODY ASSEMBLY |

Install a new gasket and the diesel throttle body with the 2 bolts and 2 nuts.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Connect the 2 connectors.

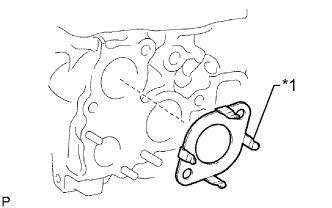

| 21. INSTALL WATER OUTLET |

Install a new gasket to the cylinder head as shown in the illustration.

Text in Illustration *1 Claw - HINT:

- Make sure the claws of the gasket face the water outlet.

|

Install the water outlet with the 2 bolts.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

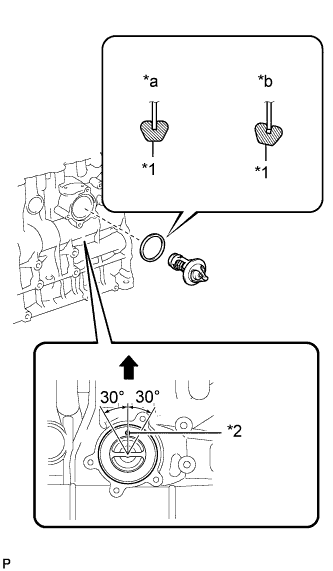

| 22. INSTALL THERMOSTAT |

Install a new gasket to the thermostat.

Text in Illustration *1 Gasket *2 Jiggle Valve *a CORRECT *b INCORRECT

Upward - NOTICE:

- When installing the gasket to the thermostat, be careful not to deform the gasket. Make sure that the groove of the gasket is properly installed to the thermostat as shown in the illustration.

|

Insert the thermostat into the cylinder block with the jiggle valve facing straight upward.

- HINT:

- The jiggle valve may be set within 30° of either side of the prescribed position.

| 23. INSTALL WATER INLET |

Install the wire harness clamp bracket to the water inlet with the bolt.

- Torque:

- 13 N*m{128 kgf*cm, 9 ft.*lbf}

Install the water inlet with the 3 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Connect the wire harness clamp.

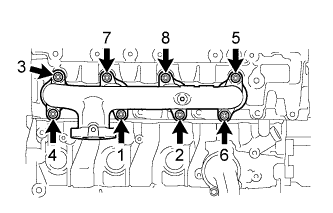

| 24. INSTALL EXHAUST MANIFOLD |

Temporarily install a new gasket, the exhaust manifold, 8 new collars and the 8 plate washers to the cylinder head with 8 new nuts.

Tighten the 8 nuts in the order shown in the illustration.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

- NOTICE:

- Make sure that the side of the collar with the smaller diameter faces the exhaust manifold.

|

| 25. INSTALL TURBOCHARGER SUB-ASSEMBLY |

| 26. INSTALL NO. 1 COMPRESSOR MOUNTING BRACKET (w/ Air Conditioning System) |

Install the No. 1 compressor mounting bracket with the 4 bolts.

- Torque:

- 45 N*m{459 kgf*cm, 33 ft.*lbf}

| 27. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY |

Install the V-ribbed belt tensioner with the 4 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

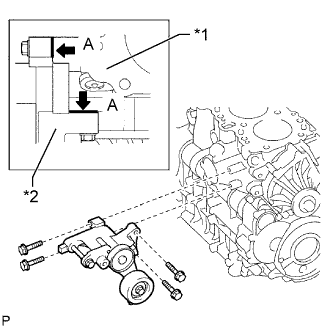

Text in Illustration *1 Cylinder Block *2 V-ribbed Belt Tensioner - HINT:

- Firmly press and hold the V-ribbed belt tensioner against the cylinder block to eliminate any gaps in the areas labeled A in the illustration. Then uniformly tighten the 4 bolts.

|

| 28. INSTALL GENERATOR BRACKET |

Install the generator bracket with the bolt.

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

| 29. INSTALL GENERATOR ASSEMBLY |

|

Install the generator with the 2 bolts.

- Torque:

- for bolt A:

- 62 N*m{632 kgf*cm, 46 ft.*lbf}

- for bolt B:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

Install the generator wire with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Connect the generator connector.

| 30. INSTALL NO. 2 IDLE PULLEY ASSEMBLY |

Install the spacer, No. 2 idle pulley and pulley plate with the bolt.

- Torque:

- 45 N*m{459 kgf*cm, 33 ft.*lbf}

| 31. INSTALL NO. 1 INTERCOOLER SUPPORT BRACKET |

Install the No. 1 intercooler support bracket with the 2 bolts.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf}

| 32. INSTALL NO. 2 INTERCOOLER SUPPORT BRACKET |

Install the No. 2 intercooler support bracket with the 2 bolts.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf}

| 33. INSTALL CRANKSHAFT PULLEY |

Align the keyway of the pulley with the key located on the crankshaft, and then slide the pulley into place to install it.

Using SST, install the pulley bolt.

- SST

- 09213-58014

09330-00021

- Torque:

- 365 N*m{3722 kgf*cm, 269 ft.*lbf}

|

| 34. INSTALL NO. 1 TIMING BELT IDLER SUB-ASSEMBLY |

Using a 10 mm hexagon wrench, install a new washer and the No. 1 timing belt idler with the bolt.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

Check that the idler pulley moves smoothly.

If the idler pulley does not move smoothly, check the installation condition of the idler and washer.

| 35. INSTALL TIMING BELT |

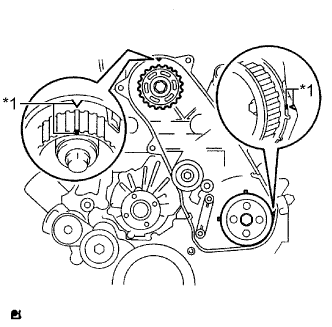

Check that the timing marks are aligned as shown in the illustration.

Text in Illustration *1 Timing Mark - NOTICE:

- Make sure that the engine is cold.

- When turning the crankshaft, the valve heads will hit against the piston. Do not turn the crankshaft more than necessary.

- HINT:

- If reusing the timing belt, align the points marked during removal, and install the belt with the arrow pointing in the direction of crankshaft revolution.

|

Install the timing belt to the pump drive shaft pulley, camshaft timing pulley and No. 1 timing belt idler in sequence.

Place the tensioner upright. Then set a press on the top of the tensioner.

- NOTICE:

- Do not scratch or deform the rod end.

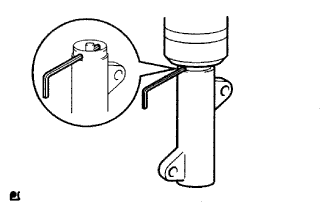

- Press in the tensioner rod.

- Protect the tip of the push rod with a cloth in order to prevent damage.

|

Using the press, slowly push in the push rod using 981 to 9800 N (100 to 999 kgf, 220 to 2203 lbf) of force.

- NOTICE:

- Do not apply a load of over 9800 N (999 kgf, 2203 lbf) to the push rod.

Align the holes of the push rod and housing. Then pass a 1.5 mm hexagon wrench through the holes to fix the push rod in place.

Temporarily install the timing belt tensioner with the 2 bolts while pushing the idler pulley toward the timing belt.

Tighten the 2 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

- NOTICE:

- Uniformly tighten the 2 bolts.

Remove the 1.5 mm hexagon wrench from the tensioner.

|

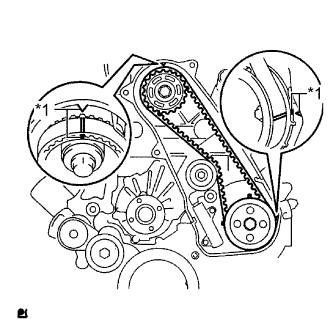

Turn the crankshaft clockwise 720° and check that the timing marks are aligned as shown in the illustration.

Text in Illustration *1 Timing Mark

|

| 36. INSTALL NO. 1 TIMING BELT COVER |

Install the timing belt cover and 6 washers with the 6 bolts.

- Torque:

- 6.0 N*m{61 kgf*cm, 53 in.*lbf}