Intake Manifold (W/O Egr Cooler) -- Installation |

- NOTICE:

- When replacing the injectors (including shuffling the injectors between the cylinders), common rail or cylinder head, it is necessary to replace the injection pipes with new ones.

- When replacing the fuel supply pump, common rail, cylinder block, cylinder head, cylinder head gasket or timing gear case, it is necessary to replace the fuel inlet pipe with a new one.

- After removing the injection pipes, clean them with a brush and compressed air.

| 1. INSTALL INTAKE MANIFOLD |

|

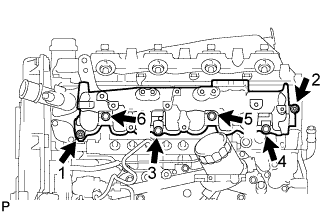

Temporarily install a new gasket and the intake manifold with the 2 nuts and 4 bolts.

Tighten the 2 nuts and 4 bolts in the order shown in the illustration.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 2. INSTALL NO. 2 NOZZLE LEAKAGE PIPE ASSEMBLY |

Temporarily install the No. 2 nozzle leakage pipe with the 3 bolts.

Temporarily install a new gasket and the union bolt.

Tighten the 3 bolts and union bolt.

- Torque:

- for bolt:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

- for union bolt:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Connect the 3 fuel hoses.

| 3. INSTALL NO. 4 INJECTION PIPE SUB-ASSEMBLY |

- NOTICE:

- When replacing an injector, it is necessary to replace the 4 injection pipes with new ones.

- Keep the joints of the injection pipe clean.

Temporarily install the No. 4 injection pipe with the union nuts.

w/ EGR Cooler:

Install the bolt.- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

- NOTICE:

- If an injection pipe clamp is removed from the No. 4 injection pipe, replace the injection pipe clamp with a new one.

- Make sure that the inner rubbers of the injection pipe fit inside the clamps.

- When installing the pipe, check that the inner rubbers and the clamps are in their proper positions.

w/o EGR Cooler:

Install the 2 bolts.- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

- NOTICE:

- If an injection pipe clamp is removed from the No. 4 injection pipe, replace the injection pipe clamp with a new one.

- Make sure that the inner rubbers of the injection pipe fit inside the clamps.

- When installing the pipe, check that the inner rubbers and the clamps are in their proper positions.

Using a 17 mm union nut wrench, tighten the injection pipe union nuts on the common rail side.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

Using a union nut wrench, tighten the injection pipe union nuts on the injector side.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

| 4. INSTALL NO. 1, NO. 2 AND NO. 3 INJECTION PIPE SUB-ASSEMBLY |

- NOTICE:

- When replacing an injector, it is necessary to replace the 4 injection pipes with new ones.

- Keep the joints of the injection pipes clean.

Temporarily install the No. 1, No. 2 and No. 3 injection pipes with the union nuts.

w/ EGR Cooler:

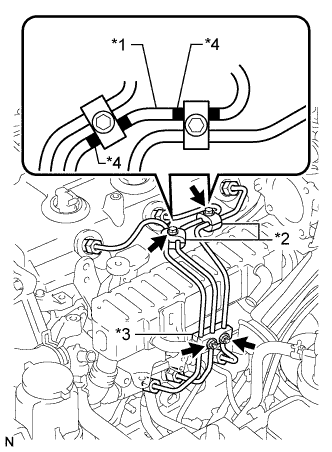

Install the No. 2 and No. 3 injection pipe clamps with the 2 bolts and 2 nuts as shown in the illustration.- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Text in Illustration *1 No. 2 Injection Pipe *2 No. 2 Injection Pipe Clamp *3 No. 3 Injection Pipe Clamp *4 Painted Mark - HINT:

- If the painted mark on the No. 2 injection pipe has disappeared, use the illustration as a reference to install the clamps.

|

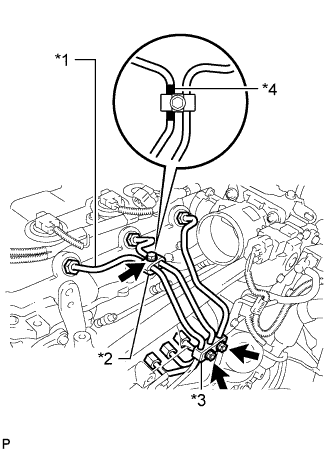

w/o EGR Cooler:

Install the No. 2 and No. 3 injection pipe clamps with the bolt and 2 nuts as shown in the illustration.- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Text in Illustration *1 No. 1 Injection Pipe *2 No. 2 Injection Pipe Clamp *3 No. 3 Injection Pipe Clamp *4 Painted Mark - HINT:

- If the painted mark on the No. 1 injection pipe has disappeared, use the illustration as a reference to install the clamps.

|

Using a 17 mm union nut wrench, tighten the injection pipe union nuts on the common rail side.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

Using a 17 mm union nut wrench, tighten the injection pipe union nuts on the injector side.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

| 5. INSTALL ELECTRIC EGR CONTROL VALVE ASSEMBLY (w/ EGR System) |

w/ EGR Cooler:

Install a new gasket and electric EGR control valve to the EGR valve adapter with the 2 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

- HINT:

- Make sure the claws of the gasket face the electric EGR control valve.

Text in Illustration *1 EGR Cooler *2 New Gasket *3 Electric EGR Control Valve *4 Claw

w/o EGR Cooler:

Install a new gasket and the electric EGR control valve.

Connect the EGR valve position sensor connector.

| 6. INSTALL NO. 1 EGR PIPE SUB-ASSEMBLY (w/ EGR System) |

Install 2 new gaskets and the No. 1 EGR pipe with the 2 nuts and 2 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Text in Illustration *1 Claw - HINT:

- Make sure the claws of the gasket face the No. 1 EGR pipe.

|

| 7. INSTALL INTAKE AIR CONNECTOR |

Install a new gasket and the intake air connector with the 2 nuts and bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

| 8. INSTALL NO. 2 INTAKE AIR CONNECTOR BRACKET |

Install the No. 2 intake air connector bracket with the 3 bolts.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

| 9. INSTALL ELECTRIC VACUUM REGULATING VALVE ASSEMBLY (w/ EGR System) |

Install the electric vacuum regulating valve together with the bracket with the 2 bolts.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

w/ EGR Cooler:

Connect the 4 vacuum hoses.- NOTICE:

- Install the vacuum hoses so that they completely cover the pipes.

w/o EGR Cooler:

Connect the 2 vacuum hoses.- NOTICE:

- Install the vacuum hoses so that they completely cover the pipes.

Connect the connector.

| 10. INSTALL VACUUM SWITCHING VALVE BRACKET (w/o EGR System) |

Install the vacuum switching valve bracket with the 2 bolts.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

| 11. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE |

Install a new O-ring to the engine oil level dipstick guide.

Apply a small amount of clean engine oil to the O-ring.

Install the engine oil level dipstick guide with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Install the injection pipe clamp with the bolt.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Install the engine oil level dipstick.

| 12. INSTALL MANIFOLD STAY |

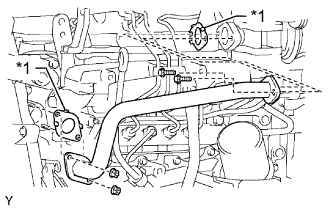

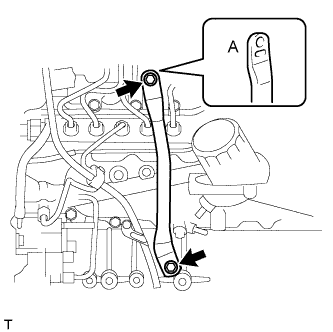

|

Install the manifold stay with the 2 bolts.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

- HINT:

- The manifold stay indented area (labeled A) must face the manifold.

| 13. INSTALL DIESEL THROTTLE BODY ASSEMBLY |

| 14. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (HILUX_TGN26 RM000004QR3009X.html).

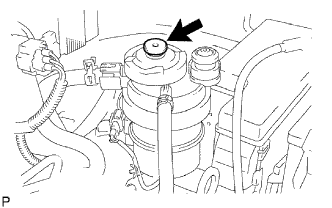

| 15. BLEED AIR FROM FUEL SYSTEM |

Using the hand pump mounted on the fuel filter cap, bleed the air from the fuel system. Continue pumping until the pump resistance increases.

- NOTICE:

- Hand pump pumping speed: Max. 2 strokes/ sec.

- The hand pump must be pushed with a full stroke during pumping.

- When the fuel pressure at the supply pump inlet port reaches a saturated pressure, the hand pump resistance increases.

- If pumping is interrupted during the air bleeding process, fuel in the fuel line may return to the fuel tank. Continue pumping until the hand pump resistance increases.

- If the hand pump resistance does not increase despite consecutively pumping 200 times or more, there may be a fuel leak between the fuel tank and fuel filter, the hand pump may be malfunctioning, or the vehicle may have run out of fuel.

- If air bleeding using the hand pump is incomplete, the common rail pressure does not rise to the pressure range necessary for normal use, and the engine cannot be started.

|

Check if the engine starts.

- NOTICE:

- Even if air bleeding using the hand pump has been completed, the starter may need to be cranked for 10 seconds or more to start the engine.

- Do not crank the engine continuously for more than 20 seconds. The battery may be discharged.

- Use a fully-charged battery.

When the engine can be started, proceed to the next step.

If the engine cannot be started, bleed the air again using the hand pump until the hand pump resistance increases (refer to the procedures above). Then start the engine.

Turn the ignition switch off.

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the intelligent tester on.

Clear the DTCs.

- w/ EGR Cooler: (HILUX_TGN26 RM000000PDK0TAX.html)

- w/o EGR Cooler: (HILUX_TGN26 RM000000PDK0SWX.html)

- w/ EGR Cooler: (HILUX_TGN26 RM000000PDK0TAX.html)

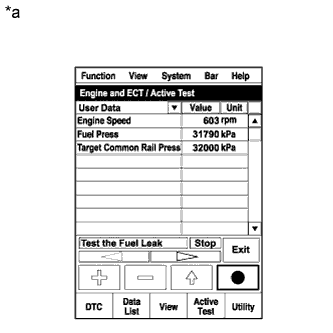

Start the engine.*1

Enter the following menus: Powertrain / Engine and ECT / Active Test / Test the Fuel Leak.*2

Text in Illustration *a Reference

(Active Test Operation)

|

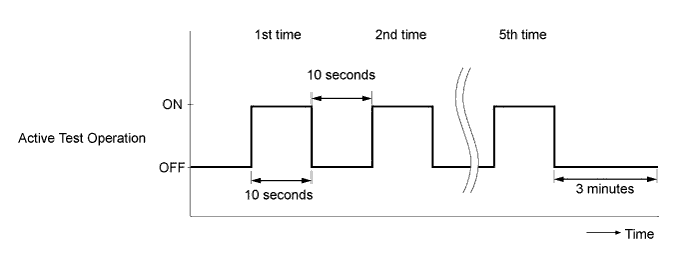

Perform the following test 5 times with on/off intervals of 10 seconds: Active Test / Test the Fuel Leak.*3

Allow the engine to idle for 3 minutes or more after performing the Active Test for the fifth time.

- HINT:

- When the Active Test "Test the Fuel Leak" is used to change the pump control mode, the actual fuel pressure inside the common rail drops below the target fuel pressure when the Active Test is off, but this is normal and does not indicate a pump malfunction.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read Current DTCs.

Clear the DTCs.

- w/ EGR Cooler: (HILUX_TGN26 RM000000PDK0TAX.html)

- w/o EGR Cooler: (HILUX_TGN26 RM000000PDK0SWX.html)

- HINT:

- It is necessary to clear the DTCs, as DTC P1604 or P1605 may be stored when air is bled from the fuel system after replacing or repairing fuel system parts.

- w/ EGR Cooler: (HILUX_TGN26 RM000000PDK0TAX.html)

Repeat steps *1 to *3.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read Current DTCs.

- OK:

- No DTCs are output.

| 16. INSPECT FOR FUEL LEAK |

- CAUTION:

- During Active Test mode, the engine speed becomes high and the combustion noise becomes loud, so pay attention.

- During Active Test mode, the fuel pressure becomes high. Be extremely careful not to expose your eyes, hands, or body to escaping fuel.

Check that there are no leaks from any part of the fuel system when the engine is stopped. If there is fuel leakage, repair or replace parts as necessary.

Start the engine and check that there are no leaks from any part of the fuel system. If there is fuel leakage, repair or replace parts as necessary.

Disconnect the return hose from the common rail.

Start the engine and check for fuel leaks from the return pipe.

If there is fuel leakage, replace the common rail.

Connect the intelligent tester to the DLC3.

Start the engine and push the intelligent tester main switch on.

Select the Fuel Leak test from the Active Test mode on the intelligent tester.

If the intelligent tester is not available, fully depress the accelerator pedal quickly. Increase the engine speed to the maximum and maintain that speed for 2 seconds. Repeat this operation several times.

Check that there are no leaks from any part of the fuel system.

- NOTICE:

- A return pipe leakage of less than 10 cc (0.6 cu in.) per minute is acceptable.

Reconnect the return hose to the common rail.