CHECK FOR FUEL LEAKS (IN HIGH-PRESSURE AREAS)

CHECK FOR ANY OTHER DTCS OUTPUT AND RECORD STORED DTC AND FREEZE FRAME DATA (PROCEDURE 2)

CHECK FUEL RECEIVER GAUGE (AMOUNT OF FUEL)

CHECK WHETHER DTC OUTPUT RECURS

CHECK FREEZE FRAME DATA (INJECTION FEEDBACK VAL #1 TO #4)

READ VALUE USING GTS (FUEL PRESS)

READ VALUE USING GTS (INJECTION FEEDBACK VAL #1 TO #4)

CLEAN FUEL FILTER CASE AND REPLACE FUEL FILTER

PERFORM ACTIVE TEST USING GTS (TEST THE FUEL LEAK)

PERFORM ACTIVE TEST USING GTS (CONTROL THE SELECT CYLINDER FUEL CUT)

INSPECT INJECTOR ASSEMBLY (INSPECTION FOR VALVE CLOSING PROBLEM)

REPLACE INJECTOR ASSEMBLY OF MALFUNCTIONING CYLINDER

READ VALUE USING GTS (ENGINE SPEED)

INSPECT ECM (FUEL PRESSURE SENSOR OUTPUT VOLTAGE)

CHECK FOR INTERMITTENT PROBLEMS

REPLACE CRANKSHAFT POSITION SENSOR

REPAIR OR REPLACE HARNESS OR CONNECTOR (ECM - FUEL PRESSURE SENSOR)

INSPECT ECM (FUEL PRESSURE SENSOR OUTPUT VOLTAGE)

REPLACE INJECTOR ASSEMBLY (FUEL PRESSURE SENSOR)

CHECK WHETHER DTC OUTPUT RECURS

DTC P0093 Fuel System Leak Detected - Large Leak |

DTC P029D Cylinder 1 - Injector Leaking |

DTC P02A1 Cylinder 2 - Injector Leaking |

DTC P02A5 Cylinder 3 - Injector Leaking |

DTC P02A9 Cylinder 4 - Injector Leaking |

DESCRIPTION

A fuel pressure sensor, which is built into the injector assembly, converts the fuel pressure to an electrical signal which is sent to the ECM. Based on this signal, the ECM controls the fuel supply pump assembly and maintains the fuel pressure in the common rail assembly at the target pressure (HILUX_TGN26 RM000000XSN02DX.html).- HINT:

- If the drop in the internal fuel pressure is large when injecting fuel, the ECM interprets this as a fault and stores P0093, P029D, P02A1, P02A5 and P02A9.

- If P0093, P029D, P02A1, P02A5 and P02A9 are present, refer to "Diagnostic Trouble Code (DTC) Table for Common Rail System" (HILUX_TGN26 RM000000XSN02DX.html).

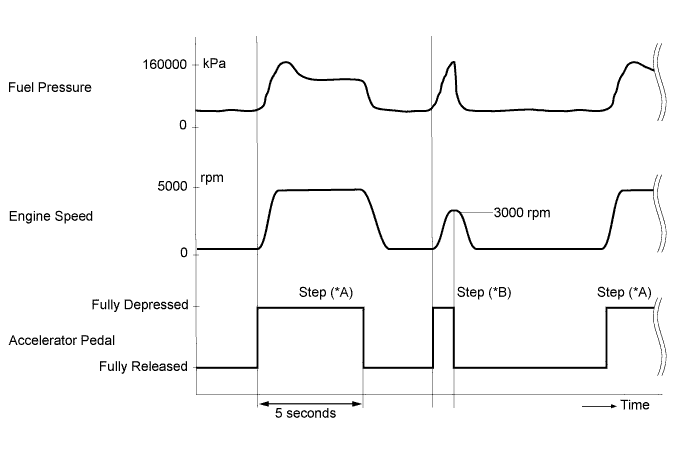

| DTC Detection Drive Pattern | DTC Detection Condition | Trouble Area |

| After idling for 60 seconds, run engine at 2500 rpm for 30 seconds. Fully depress the accelerator pedal for 5 seconds, and then release it. (*A) Rev the engine to 3000 rpm and fully release the accelerator pedal immediately after the engine reaches 3000 rpm. (*B) Repeat procedures (*A) and (*B) 5 times. | DTC P0093 Fuel pressure drop before and after fuel injection is larger than the threshold a certain number of times (0.2 seconds or more). (1 trip detection logic) |

|

| DTC P029D, P02A1, P02A5, P02A9 When the engine speed is at 650 rpm or more, the fuel pressure drop (slope of the line) is larger than the threshold and there is a time difference in the pressure drop of this cylinder compared to other cylinders for 1 second or more. (1 trip detection logic) |

| DTC No. | Data List |

| P0093 P029D P02A1 P02A5 P02A9 |

|

- HINT:

- When DTC P0093, P029D, P02A1, P02A5 and P02A9 are set, check the internal fuel pressure of the common rail by entering the following menus on the GTS: Powertrain / Engine / Data List / Fuel Press.

- Reference:

Engine Speed Fuel Press Idling Approximately 30000 to 50000 kPa 3000 rpm (No engine load) Approximately 60000 to 95000 kPa

MONITOR DESCRIPTION

- This DTC indicates that fuel leaks exist in high pressure areas in the common rail system. The ECM constantly monitors the internal fuel pressure of the common rail after the engine is started. The ECM stores this DTC if the drop in the internal fuel pressure is excessively large when injecting fuel.

In the common rail system, high-pressure fuel is always supplied to the high-pressure areas including the fuel supply pump assembly, common rail assembly, injector assemblies and piping. The ECM adjusts the suction control valve opening angle to obtain the target internal fuel pressure.

If this DTC is stored, the ECM enters fail-safe mode. In fail-safe mode, fuel supply pump assembly operation is limited. The ECM continues operating in fail-safe mode until the ignition switch is turned off.

MONITOR STRATEGY

| Required sensors | Fuel pressure sensor |

| Frequency of operation | Continuous |

| Duration | 1 second |

| MIL operation | 1 driving cycle |

INSPECTION PROCEDURE

- NOTICE:

- Soon after starting the engine, visually check for fuel leaks in the fuel line.

- After replacing the ECM, the new ECM needs registration (HILUX_TGN26 RM0000012XK05AX.html) and initialization (HILUX_TGN26 RM000000TIN058X.html).

- HINT:

- Read freeze frame data using the GTS. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.CHECK FOR FUEL LEAKS (IN HIGH-PRESSURE AREAS) |

Before starting the engine, visually check for fuel leaks from the fuel supply pump assembly, injector assembly, common rail assembly, and the fuel pipes in high-pressure areas.

- OK:

- No fuel leaks in high-pressure areas.

|

| ||||

| OK | |

| 2.CHECK FOR ANY OTHER DTCS OUTPUT AND RECORD STORED DTC AND FREEZE FRAME DATA (PROCEDURE 2) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Enter the following menus: Powertrain / Engine / Trouble Codes.

Read the DTCs and freeze frame data.

Result Result Proceed to P0093 and P13A1, P13A2, P13A3, P13A6, P13A7, P13A8, P13AB, P13AC, P13AD, P13B1, P13B2 and/or 13B3 are output C P0093 and P0335, P0339 and/or P0340 are output B Except above A

|

| ||||

|

| ||||

| A | |

| 3.CHECK FUEL RECEIVER GAUGE (AMOUNT OF FUEL) |

Check if the fuel level is low.

Result Result Proceed to The indicator (fuel warning light) is illuminated A The indicator (fuel warning light) is not illuminated B

|

| ||||

| A | |

| 4.ADD FUEL |

Add fuel.

| NEXT | |

| 5.CHECK WHETHER DTC OUTPUT RECURS |

Using the hand pump mounted on the fuel filter cap, bleed the air from the fuel system. Continue pumping until the pump resistance increases.

- NOTICE:

- Hand pump pumping speed: Max. 2 strokes/sec.

- The hand pump must be pushed with a full stroke during pumping.

- When the fuel pressure at the supply pump inlet port reaches a saturated pressure, the hand pump resistance increases.

- If pumping is interrupted during the air bleeding process, fuel in the fuel line may return to the fuel tank. Continue pumping until the hand pump resistance increases.

- If the hand pump resistance does not increase despite consecutively pumping 200 times or more, there may be a fuel leak between the fuel tank and fuel filter element sub-assembly, the hand pump may be malfunctioning, or the vehicle may have run out of fuel.

- If a large amount of air remains inside the fuel system, the common rail pressure does not rise to the pressure range necessary for normal use, and the engine cannot be started.

|

Start the engine.

- NOTICE:

- If a large amount of air remains inside the fuel system, the starter may need to be cranked for 10 seconds or more to start the engine.

- Do not crank the engine continuously for more than 20 seconds. The battery may be discharged.

- Use a fully-charged battery.

When the engine can be started, proceed to the next step.

If the engine cannot be started, bleed the air again using the hand pump until the hand pump resistance increases. Then start the engine.

Turn the ignition switch off.

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Clear the DTCs (HILUX_TGN26 RM000000PDK12TX.html).

Start the engine. (*A)

Enter the following menus: Powertrain / Engine / Active Test / Test the Fuel Leak. (*B)

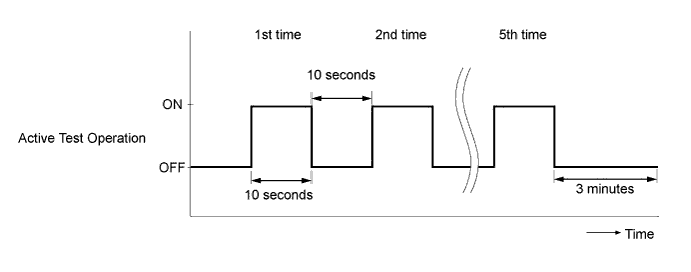

Perform the following test 5 times with on/off intervals of 10 seconds: Active Test / Test the Fuel Leak. (*C)

Allow the engine to idle for 3 minutes or more after performing the Active Test for the fifth time. (*D)

Enter the following menus: Powertrain / Engine / Trouble Codes.

Read Current DTCs.

When no DTCs are output, the air bleeding is completed.

If any DTCs are output, proceed to the next step.

Repeat steps (*A) to (*D).

Clear the DTCs (HILUX_TGN26 RM000000PDK12TX.html).

Start the engine and warm it up.

Confirm that the shift lever is in neutral and securely apply the parking brake.

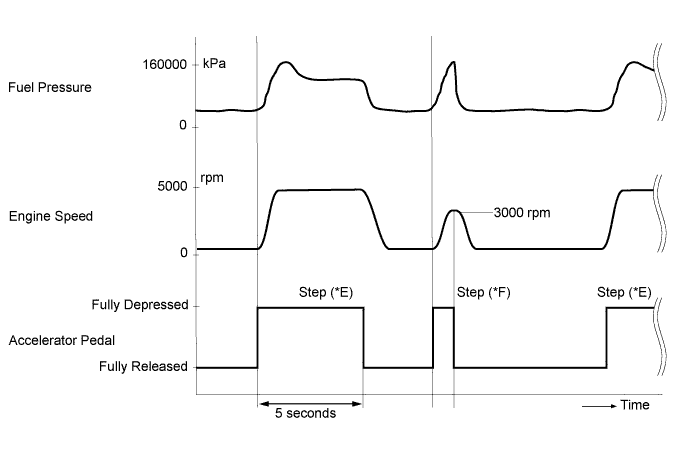

Fully depress the accelerator pedal for 5 seconds, and then release it. (*E)

Rev the engine to 3000 rpm and fully release the accelerator pedal immediately after the engine reaches 3000 rpm. (*F)

Repeat procedures (*E) and (*F) 5 times.

Enter the following menus: Powertrain / Engine / Trouble Codes.

Read Current DTCs.

Result Result Proceed to DTC is output A No DTC is output B

|

| ||||

| A | |

| 6.CHECK FREEZE FRAME DATA (INJECTION FEEDBACK VAL #1 TO #4) |

Read the value of Injection Feedback Val #1 to #4 in the freeze frame data recorded in Procedure 2.

Result Result Proceed to Injection Feedback Val for at least one cylinder is 5 mm3/st in at least 1 set of freeze frame data B Except above A - HINT:

- When there is a problem with the operation of an injector assembly due to foreign matter in the inside of the injector assembly, etc., the fuel injection volume decreases. As a result, the ECM gives instructions to increase the fuel injection volume, which causes Injection Feedback Val to increase.

|

| ||||

| A | |

| 7.READ VALUE USING GTS (FUEL PRESS) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Clear the DTCs (HILUX_TGN26 RM000000PDK12TX.html).

Enter the following menus: Powertrain / Engine / Data List / Fuel Press.

Start the engine.

Read the value of Fuel Press while cranking and idling the engine.

Result Result Proceed to The engine cannot be started or the engine can be started but Fuel Press is below 20000 kPa 2 seconds after the starter signal changes from OFF to ON B Except above A

|

| ||||

| A | |

| 8.READ VALUE USING GTS (INJECTION FEEDBACK VAL #1 TO #4) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Start the engine and warm it up.

Enter the following menus: Powertrain / Engine / Data List / Injection Feedback Val #1 to #4.

Read the values.

- Standard:

Tester Display Engine Condition* Normal Value Injection Feedback Val #1

Injection Feedback Val #2

Injection Feedback Val #3

Injection Feedback Val #4Idling -3.0 mm3/st to 3.0 mm3/st

- HINT:

- *: The A/C switch and all accessory switches should be off, the engine coolant temperature should be 70°C (158°F) or higher and the engine should be idled for 1 minute or more.

Result Result Proceed to Injection Feedback Val for at least one cylinder is more than 3 mm3/st and engine vibration is abnormally large B Except above A - HINT:

- When there is a problem with the operation of an injector assembly due to foreign matter in the inside of the injector assembly, etc., the fuel injection volume decreases. As a result, the ECM gives instructions to increase the fuel injection volume, which causes Injection Feedback Val to increase.

- The ECM controls the system so that the sum of Injection Feedback Val for all of the cylinders is approximately 0 mm3/st. Even if the value of Injection Feedback Val for a cylinder is less than -3.0 mm3/st (-3.0 mm3/st is the lowest normal value), as long as the value of Injection Feedback Val for each of the other cylinders is 3.0 mm3/st or less, the injector assemblies are not malfunctioning.

|

| ||||

| A | |

| 9.CHECK ENGINE SPEED |

Start the engine and drive the vehicle until the engine coolant temperature reaches 60°C (140°F) or higher.

Stop the vehicle and allow the engine to idle.

While checking the tachometer, fully depress the accelerator pedal for 5 seconds, and then release it.*1

Repeat procedure *1 5 times.

Result Result Proceed to No problems such as sluggishness or variations in the tachometer reading A Except above B

|

| ||||

| A | |

| 10.CHECK FREEZE FRAME DATA |

Read the value of Injector Leaking Count #1 to #4, and i-ART Learning Status History #1 to #4 in the freeze frame data recorded in Procedure 2.

- Result:

- If Injector Leaking Count #1 to #4 displays a value of 1 or higher, or i-ART Learning Status History #1 to #4 displays 1 Trip or more, the injector assembly for that cylinder needs to be replaced.

- NOTICE:

- In order to prevent foreign matter from entering the fuel lines, do not replace the injectors at this time. Replace the injectors after performing step 16.

| NEXT | |

| 11.CLEAN FUEL FILTER CASE AND REPLACE FUEL FILTER |

Clean the fuel filter case and replace the fuel filter.

- HINT:

- Be sure to clean the inside of the fuel filter case as the fuel injectors may not operate properly if the fuel filter is installed with foreign matter remaining inside the fuel filter case.

| NEXT | |

| 12.BLEED AIR FROM FUEL SYSTEM |

Bleed the air from the fuel system (HILUX_TGN26 RM000002SY802GX_01_0002.html).

| NEXT | |

| 13.PERFORM ACTIVE TEST USING GTS (TEST THE FUEL LEAK) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Start the engine.

Enter the following menus: Powertrain / Engine / Active Test / Test the Fuel Leak / Data List / Fuel Press, Target Common Rail Pressure, and Target Pump SCV Current.

Take a snapshot with the GTS during the Active Test.

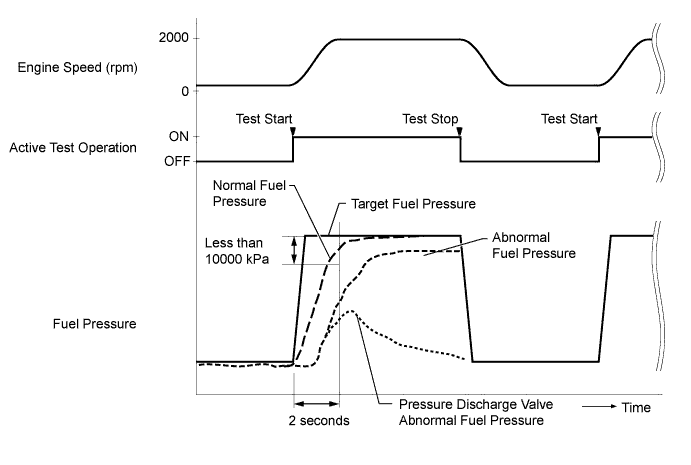

Measure the difference between the target fuel pressure (Target Common Rail Pressure) and the actual fuel pressure (Fuel Press) when the "Test the Fuel Leak" Active Test is performed (HILUX_TGN26 RM0000012X105ZX.html).

- HINT:

- In order to obtain an exact measurement, perform the Active Test 5 times and measure the difference once each time the Active Test is performed.

- OK:

- The difference between the target fuel pressure and the actual fuel pressure 2 seconds after the Active Test starts is less than 10000 kPa.

- HINT:

- "Target Common Rail Pressure" is the target fuel pressure controlled by the ECM.

- "Fuel Press" is the actual fuel pressure.

Result Result Proceed to The difference between the target fuel pressure and the actual fuel pressure 2 seconds after the Active Test starts is less than 10000 kPa A Except above B

|

| ||||

| A | |

| 14.PERFORM ACTIVE TEST USING GTS (CONTROL THE SELECT CYLINDER FUEL CUT) |

- HINT:

- Use this Active Test to determine the malfunctioning cylinder.

Connect the GTS to the DLC3.

Start the engine and turn the GTS on.

Enter the following menus: Powertrain / Engine / Active Test / Control the Select Cylinder Fuel Cut.

- HINT:

- If the engine idle speed does not change when an injector assembly is disabled, the cylinder being tested is malfunctioning. Record any malfunctioning cylinders.

- If the cylinder being tested is normal, there will be a significant change in idle speed when the fuel injection is stopped for that cylinder.

|

| ||||

| 15.INSPECT INJECTOR ASSEMBLY (INSPECTION FOR VALVE CLOSING PROBLEM) |

Remove the glow plug for all the cylinders (HILUX_TGN26 RM000000JIT00TX.html).

Visually check if there is fuel on the glow plugs.

- HINT:

- If there is fuel on a glow plug assembly, fuel may be leaking from an injector assembly.

- After replacing an injector assembly, make sure that the common rail pressure (fuel pressure) is within 5000 kPa (51.0 kgf/cm2, 725 psi) of the target fuel pressure while cranking the engine.

- If there is fuel on a glow plug assembly, fuel may have mixed with the engine oil. Check the engine oil amount and whether the engine oil smells of diesel fuel. If the oil level is above the full line or the engine oil smells of diesel fuel, replace the engine oil.

Install the glow plug (HILUX_TGN26 RM000000JIQ00UX.html).

| NEXT | |

| 16.REPLACE INJECTOR ASSEMBLY OF MALFUNCTIONING CYLINDER |

- NOTICE:

- Replace the injector assembly of the cylinder which displays a value of 3.0 mm3/st or higher for Injection Feedback Val #1 to #4 in step 8.

- Replace the injector assembly determined to be the problem in step 10 and any other injector assemblies which were determined to be malfunctioning in the steps up until this point.

Replace the injector assembly of the malfunctioning cylinder (HILUX_TGN26 RM0000044TN00PX.html).

- NOTICE:

- When replacing the injector assembly for a cylinder, always be sure to use a new injection pipe.

- Follow the procedure in the repair manual and temporarily install the injection pipes and nozzle leakage pipe, and then correctly position the injector assemblies. After that, tighten parts according to the torque specifications.

- If the installation procedure is not performed correctly, injector assemblies may become out of position, which may cause the injector assemblies to deteriorate, resulting in malfunctions.

- If an injector assembly deteriorates and malfunctions, other problems such as knocking, rough idle, etc. may occur.

- If an injector assembly becomes out of position, it is possible that the seal between the injector assembly and injection pipe may become incomplete, resulting in a fuel leak.

| NEXT | |

| 17.BLEED AIR FROM FUEL SYSTEM |

Bleed the air from the fuel system (HILUX_TGN26 RM000002SY802GX_01_0002.html).

|

| ||||

| 18.READ VALUE USING GTS (ENGINE SPEED) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Enter the following menus: Powertrain / Engine / Data List / Engine Speed.

Read the value while cranking and idling the engine.

- Standard:

Tester Display Engine Condition Specified Condition Engine Speed Cranking 50 to 400 rpm Idling with warm engine 700 to 800 rpm

- HINT:

- The value should be the same as the actual engine speed and displayed with no interruption on the GTS.

|

| ||||

| OK | |

| 19.INSPECT ECM (FUEL PRESSURE SENSOR OUTPUT VOLTAGE) |

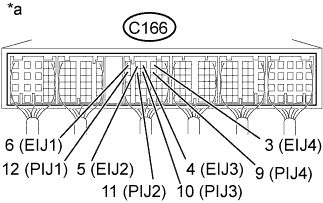

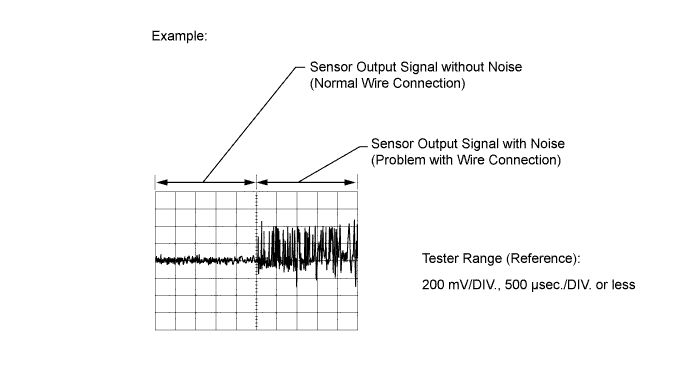

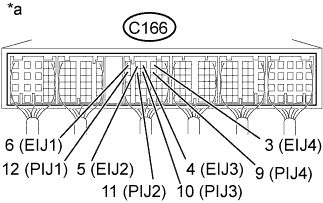

Connect the positive (+) probe of an oscilloscope to the PIJ terminal of the ECM connector and the negative (-) probe to the EIJ terminal of the ECM.

Text in Illustration *a Component with harness connected

(ECM)

|

Turn the ignition switch to ON.

Check for any noise in the waveform when vibration is applied to the wire harness and connectors between the injector assembly and ECM.

- Standard Voltage:

Tester Connection Condition Specified Condition C166-12 (PIJ1) - C166-6 (EIJ1) Vibration is applied to the wire harness and connectors No noise in the waveform C166-11 (PIJ2) - C166-5 (EIJ2) C166-10 (PIJ3) - C166-4 (EIJ3) C166-9 (PIJ4) - C166-3 (EIJ4)

Result Result Proceed to MIL comes on or noise present in the waveform B Except above A

|

| ||||

| A | |

| 20.CHECK FOR INTERMITTENT PROBLEMS |

Check for intermittent problems (HILUX_TGN26 RM000000PDQ0YUX.html).

|

| ||||

| 21.REPLACE CRANKSHAFT POSITION SENSOR |

Replace the crankshaft position sensor (HILUX_TGN26 RM0000013Z6019X.html).

- HINT:

- Before replacing the crankshaft position sensor, perform a wire harness inspection and if there are any problems with the wire harness, repair or replace it.

|

| ||||

| 22.REPAIR OR REPLACE HARNESS OR CONNECTOR (ECM - FUEL PRESSURE SENSOR) |

Repair or replace the harness or connector.

| NEXT | |

| 23.INSPECT ECM (FUEL PRESSURE SENSOR OUTPUT VOLTAGE) |

Connect the positive (+) probe of an oscilloscope to the PIJ terminal of the ECM connector and the negative (-) probe to the EIJ terminal of the ECM.

Text in Illustration *a Component with harness connected

(ECM)

|

Turn the ignition switch to ON.

Check for any noise in the waveform when vibration is applied to the wire harness and connectors between the injector assembly and ECM.

- Standard Voltage:

Tester Connection Condition Specified Condition C166-12 (PIJ1) - C166-6 (EIJ1) Vibration is applied to the wire harness and connectors No noise in the waveform C166-11 (PIJ2) - C166-5 (EIJ2) C166-10 (PIJ3) - C166-4 (EIJ3) C166-9 (PIJ4) - C166-3 (EIJ4)

Result Result Proceed to MIL comes on or noise present in the waveform A Except above B

|

| ||||

| A | |

| 24.REPLACE INJECTOR ASSEMBLY (FUEL PRESSURE SENSOR) |

Replace the injector assembly (HILUX_TGN26 RM0000044TN00PX.html).

- HINT:

- Before replacing the injector assembly, perform a wire harness inspection and if there are any problems with the wire harness, repair or replace it.

- NOTICE:

- When replacing the injector assembly for a cylinder, always be sure to use a new injection pipe.

- Follow the procedure in the repair manual and temporarily install the injection pipes and nozzle leakage pipe, and then correctly position the injector assemblies. After that, tighten parts according to the torque specifications.

- If the installation procedure is not performed correctly, injector assemblies may become out of position, which may cause the injector assemblies to deteriorate, resulting in malfunctions.

- If an injector assembly deteriorates and malfunctions, other problems such as knocking, rough idle, etc. may occur.

- If an injector assembly becomes out of position, it is possible that the seal between the injector assembly and injection pipe may become incomplete, resulting in a fuel leak.

| NEXT | |

| 25.BLEED AIR FROM FUEL SYSTEM |

Bleed the air from the fuel system (HILUX_TGN26 RM000002SY802GX_01_0002.html).

|

| ||||

| 26.CHECK WHETHER DTC OUTPUT RECURS |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Enter the following menus: Powertrain / Engine / Trouble Codes.

Clear the DTCs (HILUX_TGN26 RM000000PDK12TX.html).

Start the engine.

Warm up the engine (engine coolant temperature is 70°C (158°F) or higher).

Confirm that the shift lever is in neutral and securely apply the parking brake.

Fully depress the accelerator pedal for 5 seconds, and then release it. (*A)

Rev the engine to 3000 rpm and fully release the accelerator pedal immediately after the engine reaches 3000 rpm. (*B)

Repeat procedures (*A) and (*B) 5 times.

Enter the following menus: Powertrain / Engine / Trouble Codes.

Read the DTCs.

- OK:

- No DTCs are output.

| NEXT | ||

| ||