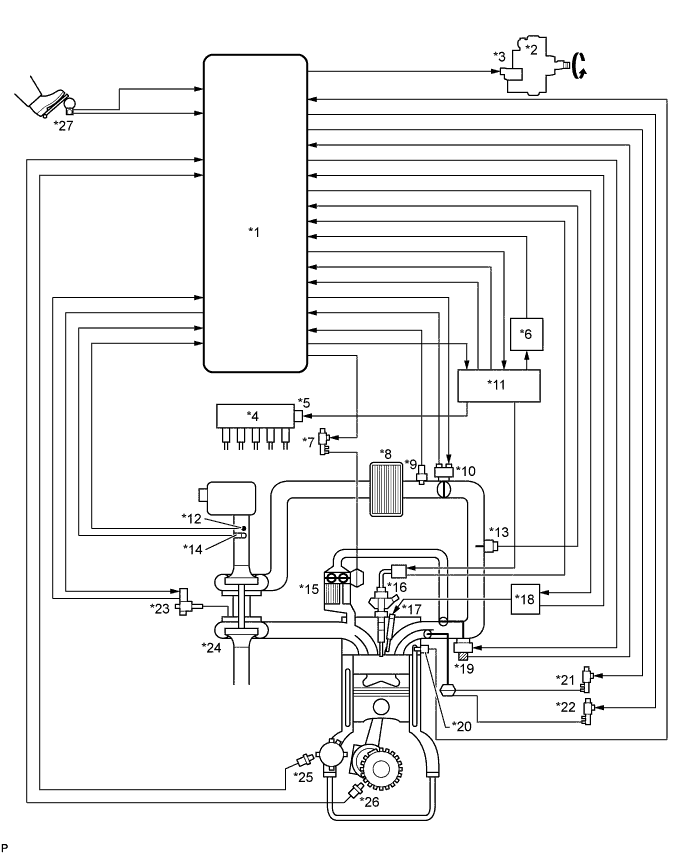

Ecd System (For I-Art) -- System Description |

| ENGINE CONTROL SYSTEM |

| *1 | ECM | *2 | Fuel Supply Pump Assembly |

| *3 | Suction Control Valve | *4 | Common Rail Assembly |

| *5 | Pressure Discharge Valve | *6 | EDU Relay |

| *7 | VSV for EGR Bypass Valve | *8 | Intercooler |

| *9 | Intake Air Temperature Sensor (Turbo) | *10 | Diesel Throttle Body Assembly |

| *11 | Injector Driver | *12 | Intake Air Temperature Sensor (Built Into Mass Air Flow Meter) |

| *13 | Manifold Absolute Pressure Sensor | *14 | Mass Air Flow Meter |

| *15 | EGR Cooler | *16 | Injector Assembly |

| *17 | Glow Plug | *18 | Glow Plug Controller |

| *19 | Electric EGR Control Valve Assembly | *20 | Engine Coolant Temperature Sensor |

| *21 | No. 1 Vacuum Switching Valve (for Swirl Control Valve) | *22 | No. 2 Vacuum Switching Valve (for Swirl Control Valve) |

| *23 | DC Motor, Nozzle Vane Position Sensor | *24 | Turbocharger Sub-assembly |

| *25 | Camshaft Position Sensor | *26 | Crankshaft Position Sensor |

| *27 | Accelerator Pedal Position Sensor | - | - |

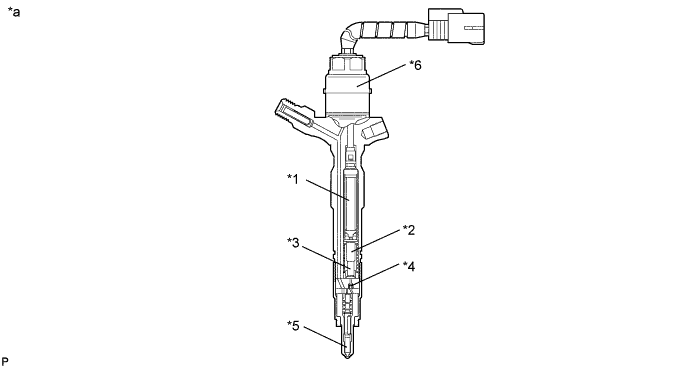

| i-ART SYSTEM |

By incorporating a pressure sensor into the injector, any changes in the internal pressure of the injectors can be confirmed at a point close to where fuel is injected.

The i-ART injector directly detects its internal fuel pressure and fuel temperature.

The ECM receives the pressure waveform signal from the pressure sensor and detects the fuel injection volume to perform so that the fuel injection volume matches the target.

Due to this system, the fuel injection precision even in the smallest amount has been improved and precise control of multilevel injection (three-stage pilot injection) has been made possible. In turn, combustion is more stable and the noise made during combustion has reduced.

The i-ART injectors automatically perform learning when they are replaced. Therefore, injector compensation code registration and pilot quantity learning is not necessary. Learning is performed while the engine is running.

| *1 | Piezo Actuator | *2 | No. 1 Piston |

| *3 | No. 2 Piston | *4 | Three-Way Valve |

| *5 | Nozzle Needle | *6 |

|

| *a | Injector Assembly Cross Section Diagram | - | - |

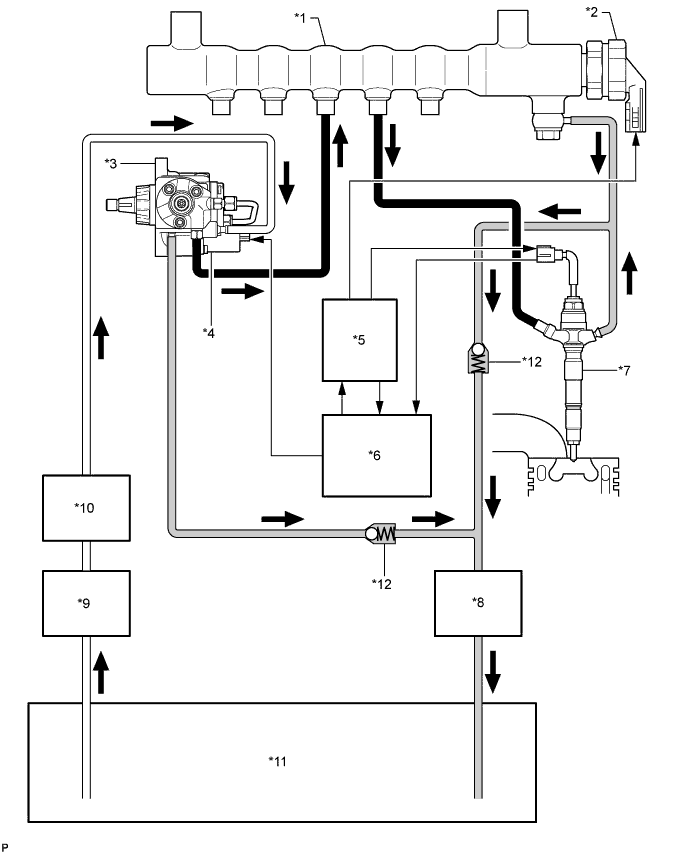

| COMMON RAIL SYSTEM DESCRIPTION |

Common rail system:

The common rail system uses high-pressure fuel for improved fuel economy. This system also provides robust engine power while suppressing engine vibration and noise.

This system stores fuel in the common rail, which has been pressurized and supplied by the fuel supply pump assembly. By storing fuel at high-pressure, the common rail system can provide fuel at stable fuel injection pressures, regardless of engine speed or engine load.

The ECM, using the injector driver, provides an electric current to the piezo actuator in each injector to regulate the fuel injection timing and volume. The ECM also monitors the internal fuel pressure of the common rail using the fuel pressure sensor built into each injector. The ECM causes the fuel supply pump assembly to supply the fuel necessary to obtain the target fuel pressure.

In addition, this system uses a piezo actuator inside each injector to open and close the fuel passages. Therefore, both fuel injection time and fuel injection volume can be precisely regulated by the ECM.

The common rail system allows for a two stage fuel injection process. In order to soften combustion shock, this system performs "pilot-injection" prior to the main fuel injection. This helps to reduce engine vibration and noise.

Text in Illustration *1 Common Rail Assembly *2 Pressure Discharge Valve *3 Fuel Supply Pump Assembly *4 Suction Control Valve *5 Injector Driver *6 ECM *7 Injector Assembly *8 Fuel Cooler *9 Fuel Filter *10 Fuel Filter (w/ Secondary Fuel Filter) *11 Fuel Tank *12 Fuel Check Valve

High Pressure Fuel Line

Return Fuel Line

Suction Fuel Line - - - HINT:

- If there is a problem with a fuel return pipe, as bleeding air from the fuel system may not be able to be performed properly in certain instances, such as after replacing an injector assembly, etc., the engine startability may deteriorate.

Common rail system components:

Component Description Common rail assembly Stores high-pressure fuel produced by fuel supply pump assembly Fuel supply pump assembly - Operated by crankshaft via gear

- Supplies high-pressure fuel to common rail assembly

Injector assembly Injects fuel to combustion chamber based on signals from ECM Fuel pressure sensor (Built into injector assembly) Monitors internal fuel pressure of injector assembly and sends signals to ECM Pressure discharge valve Based on signals from ECM, opens valve when sudden deceleration occurs, or when ignition switch is off to prevent fuel pressure from becoming too high. Suction control valve Based on signals from ECM, adjusts fuel volume supplied to common rail and regulates internal fuel pressure Check valve Keeps pressure that discharges from injector assembly - Operated by crankshaft via gear

Diagnostic trouble code (DTC) table for the common rail system:

- HINT:

- This table indicates typical DTC combinations for each malfunction occurrence.

*: There may be no DTC output depending on the condition of the malfunction.Trouble Area Malfunction DTC No. Injector assembly Open or short in injector circuit P0093*, P0201, P0202, P0203, P0204, P062D, P029D, P02A1, P02A5, P02A9 Stuck open P0093, P029D, P02A1, P02A5, P02A9 Stuck closed - Fuel pressure sensor (Built into injector assembly) Open or short in fuel pressure sensor circuit or pressure sensor range/performance P13A1, P13A2, P13A6, P13A7, P13AB, P13AC, P13B1, P13B2

P13E1, P13E2, P13E6, P13E7

P13A3, P13A8, P13AD, P13B3Pressure discharge valve Open or short in pressure discharge valve circuit P0088*, P0093*, P1229*, P1271, P1272 Stuck open P0093 Stuck closed P0088*, P1272 Suction control valve Open or short in suction control valve circuit P0627, P1229, P0088* Stuck open P0088*, P1229 Injector driver Faulty injector driver P0093*, P0201*, P0202*, P0203*, P0204*, P062D*, P1271*, P1272*, P029D*, P02A1*, P02A5*, P02A9* Common rail system (Fuel system) Fuel leaks in high-pressure area P0093 Diagnostic trouble code description for the common rail system:

DTC No. Description P0088 Internal fuel pressure too high (220000 kPa [2243 kgf/cm2, 31900 psi] or more) P0093 Fuel leaks in high-pressure areas P0201 to P0204 Open or short in No. 1 to No. 4 injector circuit P029D Cylinder 1 - Injector Leaking P02A1 Cylinder 2 - Injector Leaking P02A5 Cylinder 3 - Injector Leaking P02A9 Cylinder 4 - Injector Leaking P0627 Open or short in suction control valve circuit P062D Open or short in injector driver or injector circuit P1229 Fuel over-feed P1271 Open or short in pressure discharge valve circuit P1272 Pressure discharge valve stuck close P13A1 Open or short in No. 1 injector assembly (fuel pressure sensor) circuit (output voltage is too low) (Sub CPU) P13A2 Open or short in No. 1 injector assembly (fuel pressure sensor) circuit (output voltage is too high) (Sub CPU) P13A6 Open or short in No. 2 injector assembly (fuel pressure sensor) circuit (output voltage is too low) (Sub CPU) P13A7 Open or short in No. 2 injector assembly (fuel pressure sensor) circuit (output voltage is too high) (Sub CPU) P13AB Open or short in No. 3 injector assembly (fuel pressure sensor) circuit (output voltage is too low) (Sub CPU) P13AC Open or short in No. 3 injector assembly (fuel pressure sensor) circuit (output voltage is too high) (Sub CPU) P13B1 Open or short in No. 4 injector assembly (fuel pressure sensor) circuit (output voltage is too low) (Sub CPU) P13B2 Open or short in No. 4 injector assembly (fuel pressure sensor) circuit (output voltage is too high) (Sub CPU) P13E1 Open or short in No. 1 injector assembly (fuel pressure sensor) circuit (output voltage is too low) (Main CPU) P13E2 Open or short in No. 1 injector assembly (fuel pressure sensor) circuit (output voltage is too high) (Main CPU) P13E6 Open or short in No. 4 injector assembly (fuel pressure sensor) circuit (output voltage is too low) (Main CPU) P13E7 Open or short in No. 4 injector assembly (fuel pressure sensor) circuit (output voltage is too high) (Main CPU) P13A3 No. 1 injector assembly (fuel pressure sensor) circuit range/performance P13A8 No. 2 injector assembly (fuel pressure sensor) circuit range/performance P13AD No. 3 injector assembly (fuel pressure sensor) circuit range/performance P13B3 No. 4 injector assembly (fuel pressure sensor) circuit range/performance

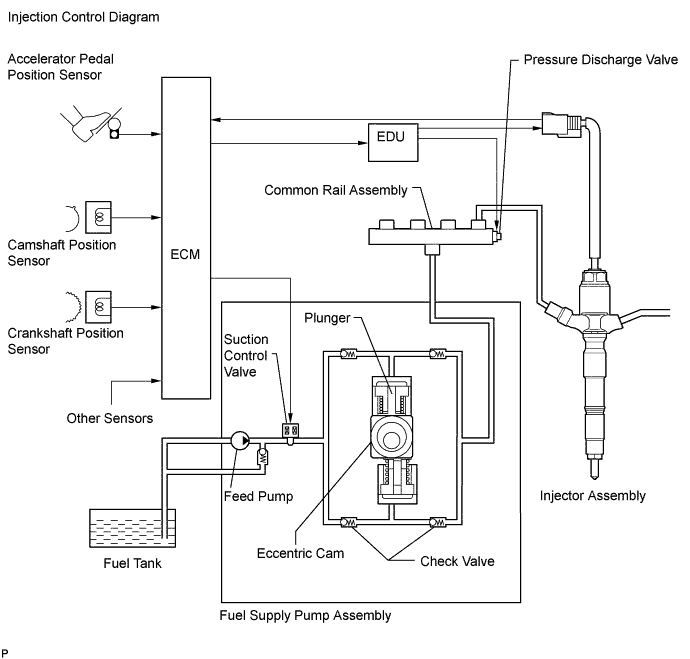

| INJECTION CONTROL SYSTEM DESCRIPTION |

The ECM determines the injection volume and injection timing based on signals from the accelerator pedal position sensor, crankshaft position sensor and camshaft position sensor. Based on the signals from the ECM, the injector driver controls the injectors. The injector driver also controls the suction control valve installed on the fuel supply pump assembly to help regulate fuel pressure.

The piezo type injector used in the 1KD-FTV engine makes noise when the engine is idling because this injector operates at high speed. Therefore, the injector driver controls the injector to operate at low speed when the engine is idling based on signals from the ECM to achieve noise reduction.

The feed pump is used to pump fuel from the fuel tank to the fuel supply pump assembly.

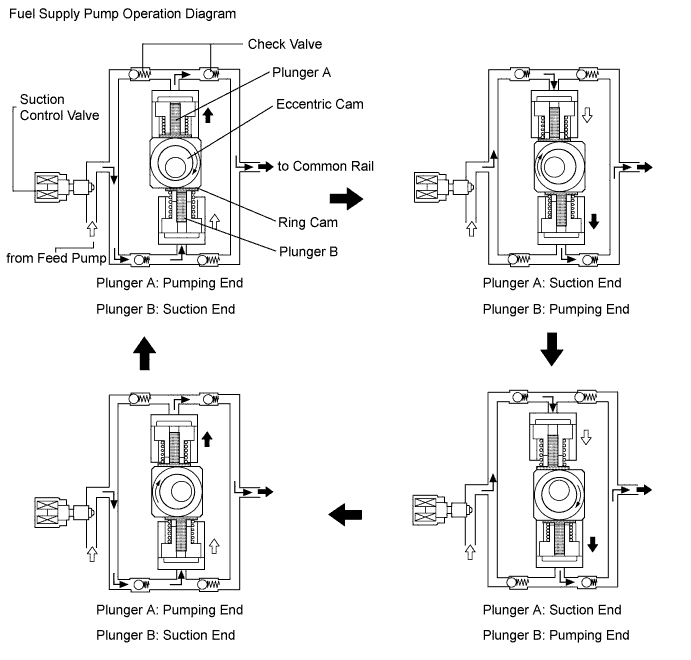

| FUEL SUPPLY PUMP OPERATION SYSTEM DESCRIPTION |

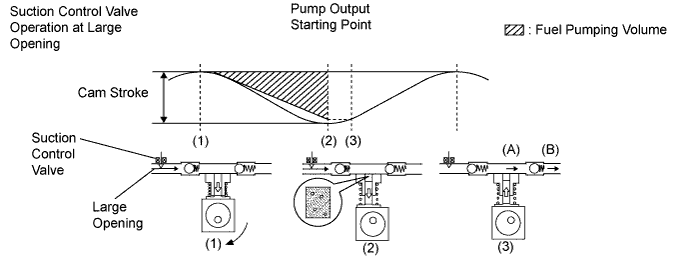

| SUCTION CONTROL VALVE OPERATION SYSTEM DESCRIPTION |

- HINT:

- The ECM controls the suction control valve operation to regulate the fuel volume that is produced by the fuel supply pump assembly for the common rail assembly. This control is performed to regulate the internal fuel pressure of the common rail to the target injection pressure.

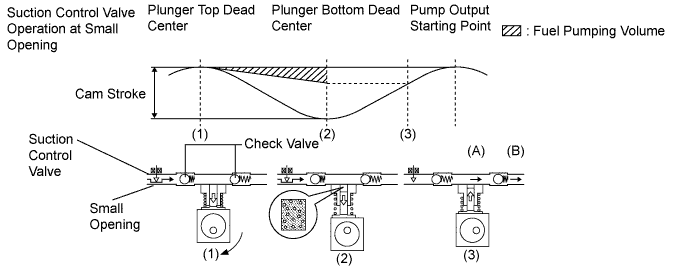

Small opening of the suction control valve:

When the opening of the suction control valve is small, the volume of supplied fuel is small.

The suction volume becomes small due to the narrow path despite the plunger stroke being full. The difference between the geometrical volume and suction volume creates a vacuum.

Pump output will start when the fuel pressure at (A) becomes higher than the common rail pressure (B).

Large opening of the suction control valve:

When the opening of the suction control valve is large, the volume of supplied fuel is large.

If the plunger stroke is full, the suction volume becomes large because of the wide path.

Pump output will start when the fuel pressure at (A) becomes higher than the common rail pressure (B).