Dtc P0037 Oxygen Sensor Heater Control Circuit Low (Bank 1 Sensor 2)

DESCRIPTION

MONITOR DESCRIPTION

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

CONFIRMATION DRIVING PATTERN

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT HEATED OXYGEN SENSOR (HEATER RESISTANCE)

CHECK TERMINAL VOLTAGE (POWER SOURCE)

CHECK HARNESS AND CONNECTOR (HEATED OXYGEN SENSOR - ECM)

CHECK WHETHER DTC OUTPUT RECURS (DTC P0037, P0038 OR P0141)

INSPECT FUSE (EFI NO. 1 FUSE)

DTC P0037 Oxygen Sensor Heater Control Circuit Low (Bank 1 Sensor 2) |

DTC P0038 Oxygen Sensor Heater Control Circuit High (Bank 1 Sensor 2) |

DTC P0141 Oxygen Sensor Heater Circuit Malfunction (Bank 1 Sensor 2) |

DESCRIPTION

Refer to DTC P0136 (Link).- HINT:

- When any of these DTCs are set, the ECM enters fail-safe mode. The ECM turns off the heated oxygen sensor heater in fail-safe mode. Fail-safe mode continues until the ignition switch is turned off.

- The ECM uses pulse width modulation to adjust the current through the heater. The heated oxygen sensor heater circuit uses a relay on the +B side of the circuit.

DTC No.

| DTC Detection Condition

| Trouble Area

|

P0037

| Heated oxygen sensor heater current is the specified value or less while the heater is operating (1 trip detection logic).

| - Open in heated oxygen sensor (sensor 2) heater circuit

- Heated oxygen sensor (sensor 2) heater

- ECM

|

P0038

| Heated oxygen sensor heater current reaches high limit

(Hybrid IC high current limiter monitor input "Fail") (1 trip detection logic).

| - Short in heated oxygen sensor (sensor 2) heater circuit

- Heated oxygen sensor (sensor 2) heater

- ECM

|

P0141

| Cumulative heater resistance correction value exceeds the threshold

(2 trip detection logic)

| - Open or short in heated oxygen sensor (sensor 2) heater circuit

- Heated oxygen sensor (sensor 2) heater

- ECM

|

MONITOR DESCRIPTION

The sensing portion of the heated oxygen sensor has a zirconia element which is used to detect the oxygen concentration in the exhaust gas. If the zirconia element is at the appropriate temperature, and the difference between the oxygen concentrations surrounding the inside and outside surfaces of the sensor is large, the zirconia element generates voltage signals. In order to increase the oxygen concentration detecting capacity of the zirconia element, the ECM supplements the heat from the exhaust with heat from a heating element inside the sensor. - Heated Oxygen Sensor Heater Range Check (P0037 and P0038):

- The ECM monitors the current applied to the heated oxygen sensor heater to check the heater for malfunctions.

If the heater current is outside the normal range, the signal transmitted by the heated oxygen sensor becomes inaccurate. When the current in the heated oxygen sensor heater is outside the normal operating range, the ECM interprets this as a malfunction in the sensor heater and stores a DTC.

- Heated Oxygen Sensor Heater Performance (P0141):

- After the accumulated heater ON time exceeds 100 seconds, the ECM calculates the heater resistance using the battery voltage and the current applied to the heater. If the resistance is above the threshold value, the ECM will determine that there is a malfunction in the heated oxygen sensor heater and set DTC P0141.

MONITOR STRATEGY

Related DTCs

| P0037: Heated oxygen sensor (sensor 2) heater range check (Low current)

P0038: Heated oxygen sensor (sensor 2) heater range check (High current)

P0141: Heated oxygen sensor (sensor 2) heater performance

|

Required Sensors/Components (Main)

| Heated oxygen sensor heater (sensor 2)

|

Required Sensors/Components (Related)

| -

|

Frequency of Operation

| Continuous: P0037, P0038

Once per driving cycle: P0141

|

Duration

| 0.2 seconds: P0038 (Case 2)

0.5 seconds: P0037

1 second: P0038 (Case 1)

10 seconds: P0141

|

MIL Operation

| Immediate: P0037, P0038

2 driving cycles: P0141

|

Sequence of Operation

| None

|

TYPICAL ENABLING CONDITIONS

AllMonitor runs whenever following DTCs are not present

| None

|

P0037Battery voltage

| 10.5 V or more, and less than 20 V

|

P0038 (Case 1)Battery voltage

| 10.5 V or more

|

Engine

| Running

|

Starter

| Off

|

P0038 (Case 2)Battery voltage

| 10.5 V or more, and less than 20 V

|

P0141All of the following conditions are met:

| -

|

Heated oxygen sensor circuit fail (P0037, P0038)

| Not detected

|

Battery voltage

| 10.5 V or more

|

Fuel cut

| Off

|

Time after fuel cut on to off

| 30 seconds or more

|

Accumulated heater on time

| 100 seconds or more

|

Learned heater off current operation

| Completed

|

Duration that heated oxygen sensor impedance is less than 15 kΩ

| 2 seconds or more

|

TYPICAL MALFUNCTION THRESHOLDS

P0037Heater output

| On

|

Heater current - Learned heater off current

| Less than 0.3 A

|

P0038 (Case 1)Learned heater off current

| More than 2 A

|

P0038 (Case 2)Hybrid IC high current limiter monitor input

| Fail

|

P0141Heater resistance

| Varies with sensor element temperature (Example: More than 23 Ω)

|

MONITOR RESULT

- Refer to Checking Monitor Status (COROLLA_ZRE142 RM000000PDR0CEX.html).

CONFIRMATION DRIVING PATTERN

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON and turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC operation) (COROLLA_ZRE142 RM000000PDK0ZAX.html).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON and turn the Techstream on [A].

- Start the engine and idle it for 5 minutes or more [B].

- With the vehicle stationary, depress the accelerator pedal and maintain an engine speed of 3000 rpm for 1 minute [C].

- Idle the engine for 5 minutes or more [D].

- Enter the following menus: Powertrain / Engine and ECT / Trouble Codes [E].

- Read the pending DTCs.

- HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

- Input the DTC: P0037, P0038 or P0141.

- Check the DTC judgment result.

Techstream Display

| Description

|

NORMAL

| - DTC judgment completed

- System normal

|

ABNORMAL

| - DTC judgment completed

- System abnormal

|

INCOMPLETE

| - DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

|

N/A

| - Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

|

- HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform steps [B] through [E] again.

- If no pending DTC is output, perform a universal trip and check for permanent DTCs (COROLLA_ZRE142 RM000000PDK0ZAX.html).

- HINT:

- If a permanent DTC is output, the system is malfunctioning.

- If no permanent DTC is output, the system is normal.

WIRING DIAGRAM

Refer to DTC P0136 (COROLLA_ZRE142 RM000000WBY0GZX_08.html).

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the Techstream. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

- Sensor 1 refers to the sensor closest to the engine assembly.

- Sensor 2 refers to the sensor farthest away from the engine assembly.

- Change the fuel injection volume using the Control the Injection Volume function provided in the Active Test and monitor the heated oxygen sensor output voltage (COROLLA_ZRE142 RM000000WBY0GZX_10.html). If the sensor output voltage does not change (almost no reaction) while performing the Active Test, the sensor may be malfunctioning.

| 1.INSPECT HEATED OXYGEN SENSOR (HEATER RESISTANCE) |

Inspect the heated oxygen sensor (COROLLA_ZRE142 RM000001CK804AX.html).

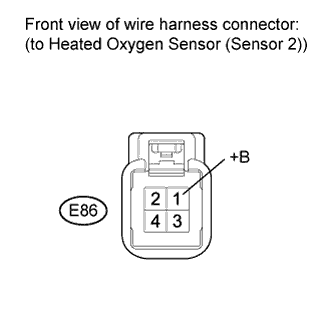

| 2.CHECK TERMINAL VOLTAGE (POWER SOURCE) |

Disconnect the heated oxygen sensor connector.

Turn the ignition switch to ON.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

E86-1 (+B) - Body ground

| Ignition switch ON

| 11 to 14 V

|

Reconnect the heated oxygen sensor connector.

| 3.CHECK HARNESS AND CONNECTOR (HEATED OXYGEN SENSOR - ECM) |

Disconnect the heated oxygen sensor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection

| Condition

| Specified Condition

|

E86-2 (HT1B) - B31-63 (HT1B)

| Always

| Below 1 Ω

|

- Standard Resistance (Check for Short):

Tester Connection

| Condition

| Specified Condition

|

E86-2 (HT1B) or B31-63 (HT1B) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the heated oxygen sensor connector.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (HEATED OXYGEN SENSOR - ECM) |

|

|

| 4.CHECK WHETHER DTC OUTPUT RECURS (DTC P0037, P0038 OR P0141) |

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Clear DTCs (COROLLA_ZRE142 RM000000PDK0ZAX.html).

Start the engine.

Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes / Pending.

Read the DTCs.

- Result:

Result

| Proceed to

|

DTC is not output

| A

|

DTC P0037, P0038 or P0141 is output

| B

|

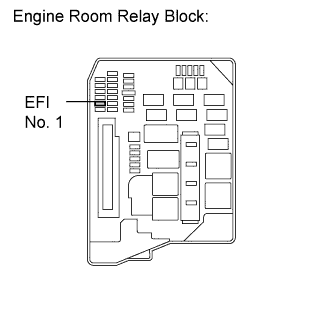

| 5.INSPECT FUSE (EFI NO. 1 FUSE) |

Remove the EFI No.1 fuse from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

EFI No. 1 fuse

| Always

| Below 1 Ω

|

Reinstall the EFI No. 1 fuse.

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR (INTEGRATION RELAY (EFI MAIN RELAY) - HEATED OXYGEN SENSOR) |

|