Vehicle Stability Control System -- Diagnosis System |

| DESCRIPTION |

The skid control ECU records DTCs when the computer detects a malfunction in the ECU itself or in its circuits.

To check the DTCs, connect the intelligent tester to the DLC3 on the vehicle. The intelligent tester enables you to clear the DTCs, activate the various actuators, and check the Freeze Frame Data and Data List.

Check the battery voltage.

- Standard voltage:

- 11 to 14 V

Check the DLC3.

The ECU uses ISO 15765-4 for communication. The terminal arrangement of the DLC3 complies with ISO 15031-3 and matches the ISO 15765-4 format.

If the result is not as specified, the DLC3 may have a malfunction. Repair or replace the harness and connector.

Verify the conditions listed in the table below.Symbols (Terminal No.) Terminal Description Condition Specified condition SIL (7) - SG (5) Bus "+" line During transmission Pulse generation CG (4) - Body ground Chassis ground Always Below 1 Ω SG (5) - Body ground Signal ground Always Below 1 Ω BAT (16) - Body ground Battery positive Always 11 to 14 V CANH (6) - CANL (14) CAN bus line *Ignition switch off 54 to 69 Ω CANH (6) - CG (4) HIGH-level CAN bus line *Ignition switch off 200 Ω or higher CANL (14) - CG (4) LOW-level CAN bus line *Ignition switch off 200 Ω or higher CANH (6) - BAT (16) HIGH-level CAN bus line *Ignition switch off 6 kΩ or higher CANL (14) - BAT (16) LOW-level CAN bus line *Ignition switch off 6 kΩ or higher - NOTICE:

- *: Before measuring the resistance, leave the vehicle as is for at least 1 minute and do not operate the ignition switch, any other switches or the doors.

- HINT:

- Connect the intelligent tester to the DLC3, turn the ignition switch on (IG) and attempt to use the tester. If the display indicates that a communication error has occurred, there is a problem either with the vehicle or with the tester.

- If communication is normal when the tester is connected to another vehicle, inspect the DLC3 on the original vehicle.

- If communication is still not possible when the tester is connected to another vehicle, the problem may be in the tester itself. Consult the Service Department listed in the tester's operator's manual.

|

| DIAGNOSIS |

If the skid control ECU detects a malfunction, the ABS warning, BRAKE warning and SLIP indicator lights will come on in order to warn the driver.

The DTCs are simultaneously stored in the memory. The DTCs can be read by connecting the SST between terminals TC and CG of the DLC3 and observing the blinking pattern of the ABS warning and SLIP indicator lights, by reading the multi information display, or by connecting the intelligent tester.

This system has a Test Mode (signal check) function (CAMRY_ACV40 RM000000XHT06DX.html).

The DTC can be read by connecting the intelligent tester and observing the blinking pattern of the ABS warning and SLIP indicator lights, by reading the multi information display.

|

| WARNING LIGHT AND INDICATOR LIGHT CHECK |

Release the parking brake.

- NOTICE:

- When releasing the parking brake, move the shift lever to the P position for safety (A/T) or set the chocks to hold the vehicle for safety (M/T).

- HINT:

- When the parking brake is applied or the level of the brake fluid is low, the BRAKE warning light comes on.

When the ignition switch is turned on (IG), check that the ABS warning, BRAKE warning and SLIP indicator lights come on for approximately 3 seconds.

- HINT:

- If the warning light and indicator light check result is not normal, proceed to troubleshooting for the ABS warning, BRAKE warning and SLIP indicator light circuits.

Trouble Area See procedure ABS warning light circuit CAMRY_ACV40 RM000000XIH095X.html BRAKE warning light circuit CAMRY_ACV40 RM000000YHG096X.html SLIP indicator light circuit CAMRY_ACV40 RM000000YHI06SX.html

|

| SYMPTOM SIMULATION |

- HINT:

- The most difficult case in troubleshooting is when no symptoms occur. In such cases, a thorough customer problem analysis must be carried out. Then the same or similar conditions and environment in which the problem occurred in the customer's vehicle should be reproduced. No matter how experienced or skilled a technician may be, if they proceeds to troubleshoot without confirming the problem symptoms, they will likely overlook something important and make a wrong guess at some points in the repair operation. This leads to a standstill in troubleshooting.

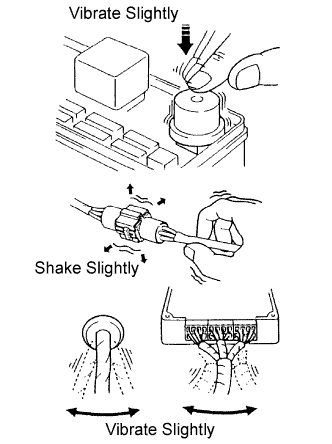

Vibration method: When vibration seems to be the major cause.

- HINT:

- Perform the simulation method only during the primary check period (for approximately 6 seconds after the ignition switch is turned on (IG)).

Slightly vibrate the part of the sensor considered to be the problem cause with your fingers and check whether the malfunction occurs.

Slightly shake the connector vertically and horizontally.

- HINT:

- Shaking the relays too strongly may result in open relays.

Slightly shake the wire harness vertically and horizontally. The connector joint and fulcrum of the vibration are the major areas to be checked thoroughly.

|