Ecd System Cranking Holding Function Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

READ VALUE OF INTELLIGENT TESTER

CHECK ECM (STSW TERMINAL VOLTAGE)

CHECK ECM (STAR OUTPUT VOLTAGE)

INSPECT CLUTCH START SWITCH

CHECK WIRE HARNESS (ECM - MAIN BODY ECU)

INSPECT ST CUT RELAY

CHECK ST CUT RELAY (RELAY HOLDER TERMINAL VOLTAGE)

CHECK WIRE HARNESS (ECM - CLUTCH START SWITCH - MAIN BODY ECU)

CHECK NO. 7 RELAY BLOCK (CHECK FOR SHORT)

CHECK WIRE HARNESS (CLUTCH START SWITCH - ECM - ST RELAY)

INSPECT BATTERY

CHECK BATTERY TERMINAL

ECD SYSTEM - Cranking Holding Function Circuit |

DESCRIPTION

The cranking holding control system keeps energizing the ST relay after the ECM detects the starter signal (STSW signal) from the main body ECU until the ECM performs a judgment of "Engine started". Furthermore, the ECM outputs an accessory cut signal (ACCR signal) to the ACC relay during cranking to prevent flickering of the combination meter, clock, audio system, and other areas.When the ECM detects the STSW signal, the ECM outputs the starter relay drive signal (STAR signal) to the starter relay through the clutch start switch, and then the engine is cranked. When the ECM receives a stable engine speed signal (NE signal) (more specifically, when the NE signal reaches a predetermined value), the ECM stops outputting the STAR signal. Also, the ECM monitors the ST relay operating conditions based on the STA terminal voltage status.

WIRING DIAGRAM

INSPECTION PROCEDURE

- ПРИМЕЧАНИЕ:

- Perform electronic throttle learning after replacing the ECM (see page RAV4_ACA30 RM000000UZ301KX.html).

| 1.READ VALUE OF INTELLIGENT TESTER |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Enter the following menu items: Powertrain / Engine and ECT / Data List / Starter Signal.

Check the result when the ignition switch is turned on (IG).

Check the result when the engine starts.

- OK:

Ignition Switch Condition

| Tester Display (Starter Signal)

|

On (IG)

| OFF

|

Engine starts

| ON

|

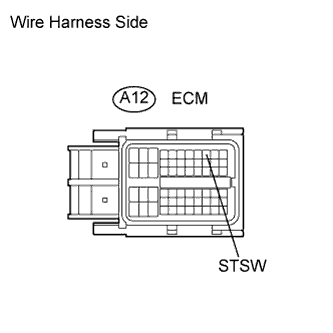

| 2.CHECK ECM (STSW TERMINAL VOLTAGE) |

Disconnect the A12 ECM connector.

Depress the clutch pedal fully.

Measure the voltage of the ECM terminal and the body ground when operating the ignition switch to start cranking.

- Standard voltage:

Tester Connection

| Specified Condition

|

A12-9 (STSW) - Body ground

| 10 to 14 V

|

Reconnect the ECM connector.

| 3.CHECK ECM (STAR OUTPUT VOLTAGE) |

Disconnect the A4 clutch start switch connector.

Measure the voltage of the terminal of clutch start switch connector and the body ground while cranking the engine.

- Standard voltage:

Tester Connection

| Specified Condition

|

A4-2 - Body ground

| 10 to 14 V

|

Reconnect the clutch start switch connector.

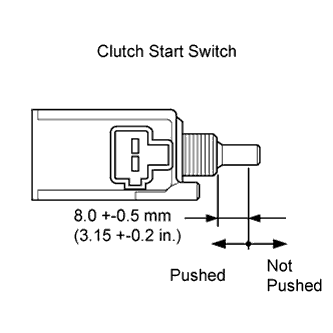

| 4.INSPECT CLUTCH START SWITCH |

Disconnect the A4 clutch start switch connector.

Measure the resistance of the terminals of the clutch start switch connector.

- Standard resistance:

Switch Condition

| Specified Condition

|

Pushed

| Below 1 Ω

|

Not pushed

| 10 kΩ or higher

|

Reconnect the clutch start switch connector.

| NG |

|

|

|

| REPLACE CLUTCH START SWITCH |

|

| 5.CHECK WIRE HARNESS (ECM - MAIN BODY ECU) |

Disconnect the E20 main body ECU connector.

Disconnect the A12 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

E20-4 (STSW) - A12-9 (STSW )

| Below 1 Ω

|

E20-4 (STSW) - Body ground

| 10 kΩ or higher

|

Reconnect the main body ECU connector.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| OK |

|

|

|

| CHECK ENTRY AND START SYSTEM |

|

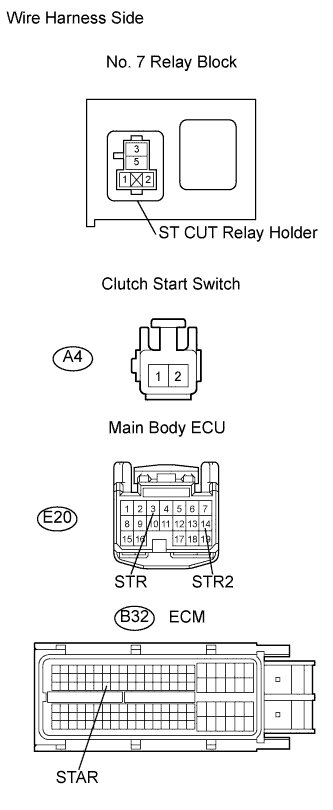

Remove the ST CUT relay from the No. 7 relay block.

Measure the resistance.

- Standard resistance:

Tester Connection

| Specified Condition

|

3 - 5

| 10 kΩ or higher

|

3 - 5

| Below 1 Ω

(When battery voltage applied to terminals 1 and 2)

|

Reinstall the relay.

| 7.CHECK ST CUT RELAY (RELAY HOLDER TERMINAL VOLTAGE) |

Remove the ST CUT relay from the No. 7 relay block.

Turn the ignition switch on (IG).

Measure the voltage of the terminals of the ST CUT relay holder.

- Standard voltage:

Tester Connection

| Specified Condition

|

1 - 2

| 10 to 14 V

|

Reinstall the relay.

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| 8.CHECK WIRE HARNESS (ECM - CLUTCH START SWITCH - MAIN BODY ECU) |

Remove the ST CUT relay from the No. 7 relay block.

Disconnect the A4 clutch start switch connector.

Disconnect the E20 main body ECU connector.

Disconnect the B32 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

ST CUT relay terminal 3 - B32-53 (STAR)

| Below 1 Ω

|

ST CUT relay terminal 3 - E20-14 (STR2)

| Below 1 Ω

|

E20-3 (STR) - ST CUT relay terminal 5

| Below 1 Ω

|

A4-2 - ST CUT relay terminal 5

| Below 1 Ω

|

ST CUT relay terminal 3 - Body ground

| 10 kΩ or higher

|

ST CUT relay terminal 5 - Body ground

| 10 kΩ or higher

|

Reinstall the ST CUT relay.

Reconnect the clutch start switch connector.

Reconnect the main body ECU connector.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| 9.CHECK NO. 7 RELAY BLOCK (CHECK FOR SHORT) |

Remove the ST CUT relay from the No. 7 relay block.

Disconnect the B32 ECM connector.

Measure the resistance of the terminals of the ST CUT relay holder.

- Standard resistance:

Tester Connection

| Specified Condition

|

No. 7 Relay block ST CUT relay terminal 3 - Body ground

| 10 kΩ or higher

|

No. 7 Relay block ST CUT relay terminal 5 - Body ground

| 10 kΩ or higher

|

Reinstall the ST CUT relay.

Reconnect the ECM connector.

| | CHECK ENTRY AND START SYSTEM |

|

|

| 10.CHECK WIRE HARNESS (CLUTCH START SWITCH - ECM - ST RELAY) |

Remove the ST relay from the No. 8 relay block.

Disconnect the A4 clutch start switch connector.

Disconnect the A12 ECM connector.

Measure the resistance of the wire harness side connector.

- Standard resistance:

Tester Connection

| Specified Condition

|

A4-1 - A12-43 (STA)

| Below 1 Ω

|

A4-1 - ST relay terminal 1

| Below 1 Ω

|

ST relay terminal 2 - Body ground

| Below 1 Ω

|

A4-1 - Body ground

| 10 kΩ or higher

|

Reinstall the ST relay.

Reconnect the clutch start switch connector.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

Check that the battery is not depleted.

- OK:

- Battery is not depleted.

| 12.CHECK BATTERY TERMINAL |

Check that the battery terminals are not loose or corroded.

- OK:

- Battery terminals are not loose or corroded.

| | REPAIR OR REPLACE BATTERY TERMINAL |

|

|

| OK |

|

|

|

| CHECK AND REPLACE STARTER POWER SOURCE CIRCUIT |

|