Fuel Injector -- Installation |

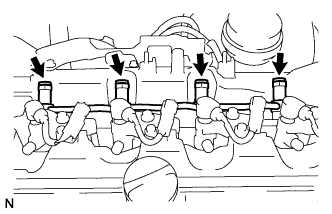

| 1. INSTALL INJECTOR ASSEMBLY |

- ПРИМЕЧАНИЕ:

- Before installing the injector, check for carbon, foreign matter, etc. on the seal surfaces of the cylinder head and injector. If there is foreign matter, remove it before installing the injector.

Install 4 new nozzle seats to the cylinder head.

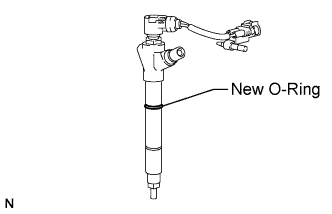

Install new O-rings to each injector.

|

Apply a light coat of engine oil to the O-rings on each injector.

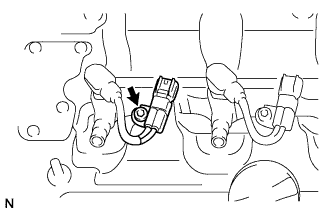

Install the 4 injectors to the cylinder head.

- ПРИМЕЧАНИЕ:

- Fit the injectors to the nozzle seats.

Temporarily install the 4 clamps to the cylinder head with the 4 bolts.

|

Using a hexagon socket wrench, tighten the 4 bolts.

- Момент затяжки:

- 9 Н*м{92 кгс*см, 80 фунт-сила-дюймов}

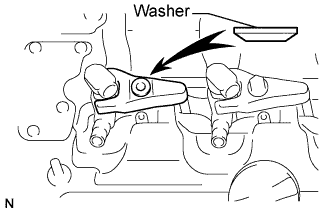

Install the nozzle holder clamps and washers as shown in the illustration.

|

Temporarily install the nozzle holder clamp bolts.

- ПРИМЕЧАНИЕ:

- Pay attention to the mounting orientation (beveled edge) of the washer.

- When temporarily attaching the nozzle holder clamp and the nozzle holder clamp bolt, be careful not to position them at an angle.

- УКАЗАНИЕ:

- Apply a light coat of engine oil on the threads of the nozzle holder clamp bolts.

Temporarily install the No. 1, No. 2, No. 3 and No. 4 injection pipe.

Temporarily install 4 new gaskets and the No. 1 leakage pipe with the 4 union bolts.

Tighten the 4 nozzle holder clamp bolts.

- Момент затяжки:

- 25 Н*м{255 кгс*см, 18 фунт-сила-футов}

| 2. INSTALL NO. 1 NOZZLE LEAKAGE PIPE ASSEMBLY |

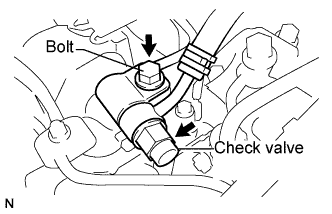

Temporarily install a new gasket, fuel check valve and bolt.

|

Tighten the 4 union bolts.

- Момент затяжки:

- 18 Н*м{184 кгс*см, 13 фунт-сила-футов}

|

Tighten the fuel check valve and bolt.

- Момент затяжки:

- 31.5 Н*м{321 кгс*см, 23 фунт-сила-футов} for fuel check valve

- 20.5 Н*м{209 кгс*см, 15 фунт-сила-футов} for bolt

| 3. INSTALL INJECTION PIPE SUB-ASSEMBLY |

- ПРИМЕЧАНИЕ:

- In a case where an injector is replaced, the injection pipes must also be replaced.

Temporarily install the 4 injection pipes.

|

Using SST, tighten the 4 nuts at the common rail end of the injection pipes.

- Специальный инструмент (SST):

- 09023-38401

- Момент затяжки:

- 27 Н*м{275 кгс*см, 20 фунт-сила-футов}

- УКАЗАНИЕ:

- Use of the proper SST is required to ensure that the correct torque is applied to the injection pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation.

If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new pipe.

Using SST, tighten the 4 nuts at the injector end of the injection pipes.

- Специальный инструмент (SST):

- 09023-38401

- Момент затяжки:

- 27 Н*м{275 кгс*см, 20 фунт-сила-футов}

- УКАЗАНИЕ:

- Use of the proper SST is required to ensure that the correct torque is applied to the injection pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation.

If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new pipe.

| 4. CONNECT ENGINE WIRE |

Connect the engine wire to the engine cover bracket.

Connect the glow plug wire harness.

Install the 2 nuts.

Install the nut and grommet.

- Момент затяжки:

- 2.2 Н*м{22 кгс*см, 19 фунт-сила-дюймов}

Connect the turbo pressure sensor connector.

Connect the discharge valve connector.

Connect the fuel pressure sensor connector.

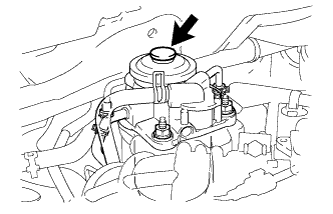

| 5. BLEED AIR FROM FUEL SYSTEM |

Using the hand pump indicated by the arrows in the illustration, bleed the fuel system. Continue pumping until pumping becomes difficult.

|

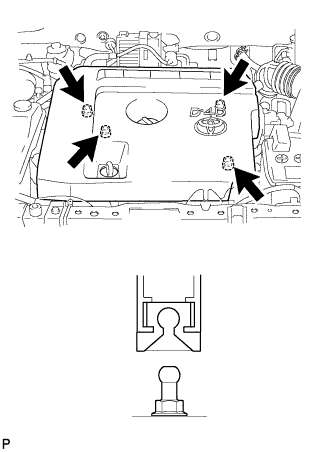

| 6. INSTALL NO. 1 ENGINE COVER |

Attach the 4 clips to install the engine cover.

|

| 7. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 8. PERFORM REGISTRATION OF INJECTOR COMPENSATION CODE |

- УКАЗАНИЕ:

- Each injector assembly has a characteristic fuel injecting behavior (see page RAV4_ACA30 RM000000TJ4007X.html).

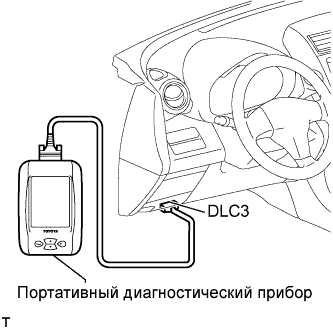

| 9. CHECK FOR FUEL LEAKS |

Perform the ACTIVE TEST.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG).

Turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Active Test.

Perform the Active Test.

Intelligent Tester Display Test Details Control Range Diagnostic Notes Test the Fuel Leak Pressurizing common rail internal fuel pressure, and checking for fuel leaks Stop/Start - Fuel pressure inside common rail pressurized to specified value and engine speed increased to 2,000 rpm when Start is selected

- Above conditions to be maintained while test is Start

- Fuel pressure inside common rail pressurized to specified value and engine speed increased to 2,000 rpm when Start is selected

|